An environmentally friendly 3D printing material processing device

A 3D printing and material processing technology, applied in the field of 3D printing, can solve the problems of low processing efficiency, material shortage, immature application, etc., and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

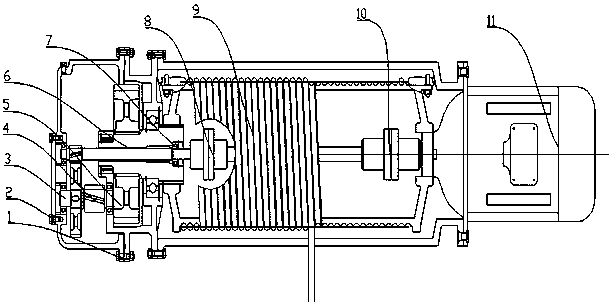

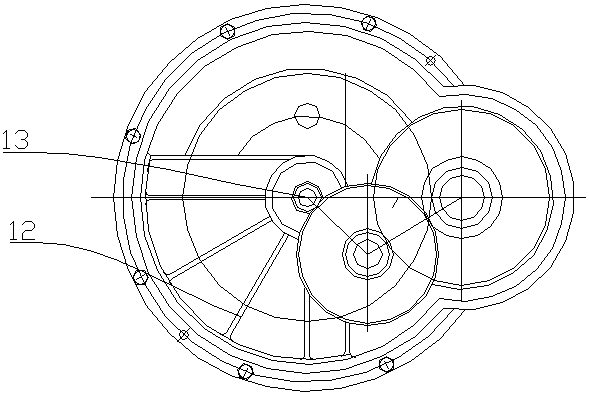

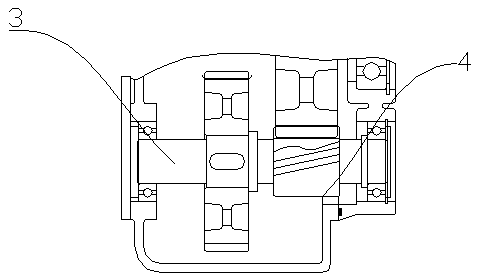

[0032] Such as Figure 1-Figure 3As shown, an environmentally friendly 3D printing material processing device includes a printing nozzle 1, a microprocessor 4, a feeder 8 and a motor 11, and a regulating valve 2 is installed outside the upper end of the printing nozzle 1 to adjust the printing frequency and speed of the printed body. A sensor 3 is installed on the inner side of the regulating valve 2, which can sense the whole process of printing, and dynamically and automatically control printing. The inner side of the sensor 3 is connected to a microprocessor 4, which can play a good role in control and processing. There is an adapter 5, which can adapt and print different materials. A telescopic shaft 6 is installed on the upper end of the adapter 5, which can be stretched and flexibly printed. The other end of the telescopic shaft 6 is equipped with a lubricator 7 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com