Graphene provided with polynitrogen coordination structure and preparation method and application thereof

A graphene and coordination technology, applied in the fields of catalysts, new materials, new energy and energy conservation and environmental protection, can solve the problems of ununified graphene preparation methods, difficulties in realization, and difficulties in compounding, and achieve efficient catalytic active sites, flexible regulation and control. ability, efficient catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

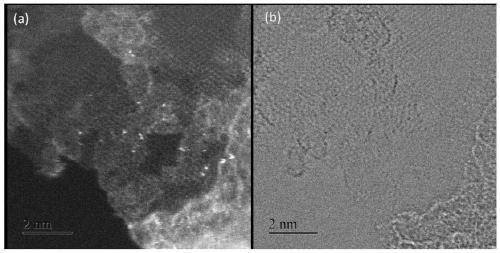

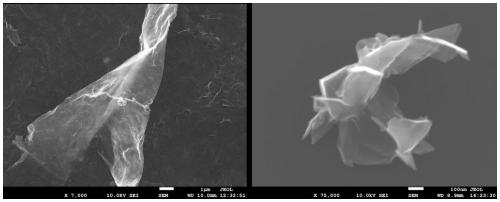

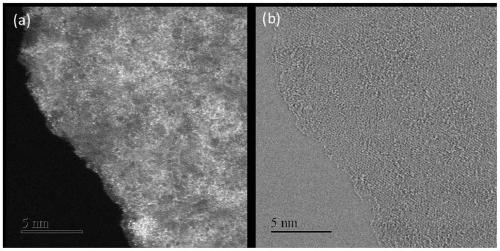

Image

Examples

Embodiment 1

[0105] Provide graphite-containing slabs and liquids. The mass of the liquid is 30 times the mass of graphite-containing slabs. Graphite strips are coated with titanium for electrolysis, and ceramic sheets are placed between each titanium strip to prevent short circuits. ; Graphite: titanium: the mass ratio of ceramics is 60%: 20%: 20%. The graphite strip is 1cm wide, and the number of slats is 11. The area of each slat is 0.2 square meters. The slats are arranged in parallel, and the distance between adjacent slats is 2 cm. The slats are isolated from each other and are airtight. Place the graphite strips in the electrolyte 1 and electrolyte 2 in turn, conduct electrolysis at room temperature with direct current, with a voltage of 1-8V (the voltage may rise spontaneously during the electrolysis process), and electrolyze each electrolyte for 24 hours. Electrolyte 1-perchloric acid aqueous solution 65%, electrolyte 2-ferric chloride, urea, melamine aqueous dispersion, the con...

Embodiment 2

[0107] Provide graphite-containing slabs and liquids. The mass of the liquid is 30 times the mass of graphite-containing slabs. Graphite strips are coated with titanium for electrolysis, and ceramic sheets are placed between each titanium strip to prevent short circuits. ; Graphite: titanium: the mass ratio of ceramics is 60%: 20%: 20%. The graphite strip is 1cm wide, and the number of slats is 11. The area of each slat is 0.2 square meters. The slats are arranged in parallel, and the distance between adjacent slats is 2 cm. The slats are isolated from each other and are airtight. The graphite strips were placed in the electrolyte solution 1, electrolyte solution 2, and electrolyte solution 3 respectively in turn, and electrolyzed at room temperature by direct current, with a voltage of 1-8V, and each electrolyte solution was electrolyzed for 24 hours. Electrolyte 1-perchloric acid aqueous solution 65%, electrolyte 2-ferric chloride, urea, melamine aqueous dispersion, the co...

Embodiment 3

[0109] Provide graphite-containing slabs and liquids. The mass of the liquid is 30 times the mass of graphite-containing slabs. Graphite strips are coated with titanium for electrolysis, and ceramic sheets are placed between each titanium strip to prevent short circuits. ; Graphite: titanium: the mass ratio of ceramics is 60%: 20%: 20%. The graphite strip is 1cm wide, and the number of slats is 11. The area of each slat is 0.2 square meters. The slats are arranged in parallel, and the distance between adjacent slats is 2 cm. The slats are isolated from each other and are airtight. The intercalated graphite strips are halogen intercalated graphite strips, which are obtained by intercalating halogen ions in graphite under the condition of electrification and electrolysis. Graphite strips are used as electrodes, placed in a water-in-salt electrolyte, energized and electrolyzed to obtain chlorine-intercalated graphite. The concentration of lithium chloride in the water-in-salt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com