Carbon nano tube toughened SiBCN(O) metal-based ceramic coating and preparation method thereof

A technology of ceramic coating and carbon nanotubes, which is applied in the field of SiBCN metal-based ceramic coating and its preparation, can solve the problems of complexity and high production cost, and achieve the effects of improving toughness, reducing energy consumption, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A preparation method of SiBCN (O) metal-based ceramic coating, comprising the following steps:

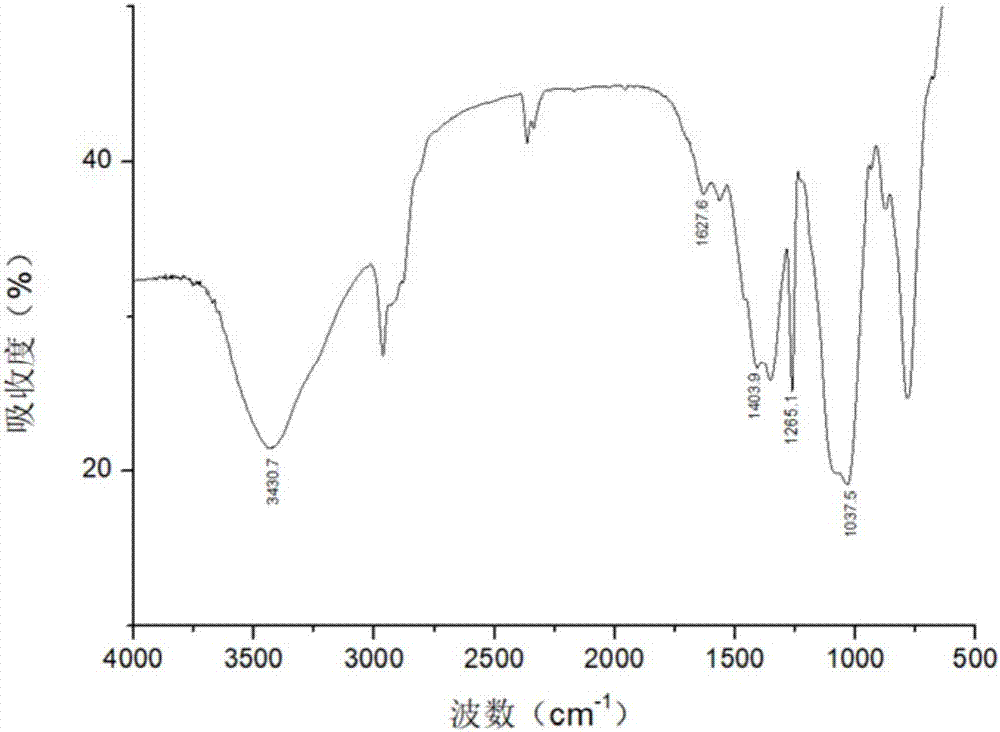

[0031] (1) Preparation of polyborosilazane

[0032] Repeatedly evacuate the Schlenk reaction bottle and fill it with high-purity argon for at least three times to ensure that the air and water in the bottle are completely discharged. Then add 100 ml of anhydrous tetrahydrofuran with a syringe, and then add 10 g of vinyl chlorosilane and 1 g of phenyl chlorosilane. Pass high-purity ammonia gas (99.9999%) at 0-10°C for 2.5 hours, and then react for 2 hours under the protection of argon; distill the solvent under reduced pressure to obtain viscous liquid polysilazane; under the protection of argon , 12.5ml of toluene solution (2M) of borane dimethyl sulfide was slowly added dropwise at 0°C. After the dropwise addition, the temperature was raised to room temperature, reacted for 24 hours, and distilled under reduced pressure to obtain polyborosilazane; the above operations were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com