Mixed type connector plug

A connector plug and mixed-type technology, applied in the field of mixed-type connector plugs, can solve the problems of increased product cost, wear and tear, wasting time, etc., and achieve the effects of high positioning accuracy, good anti-vibration, and convenient product installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

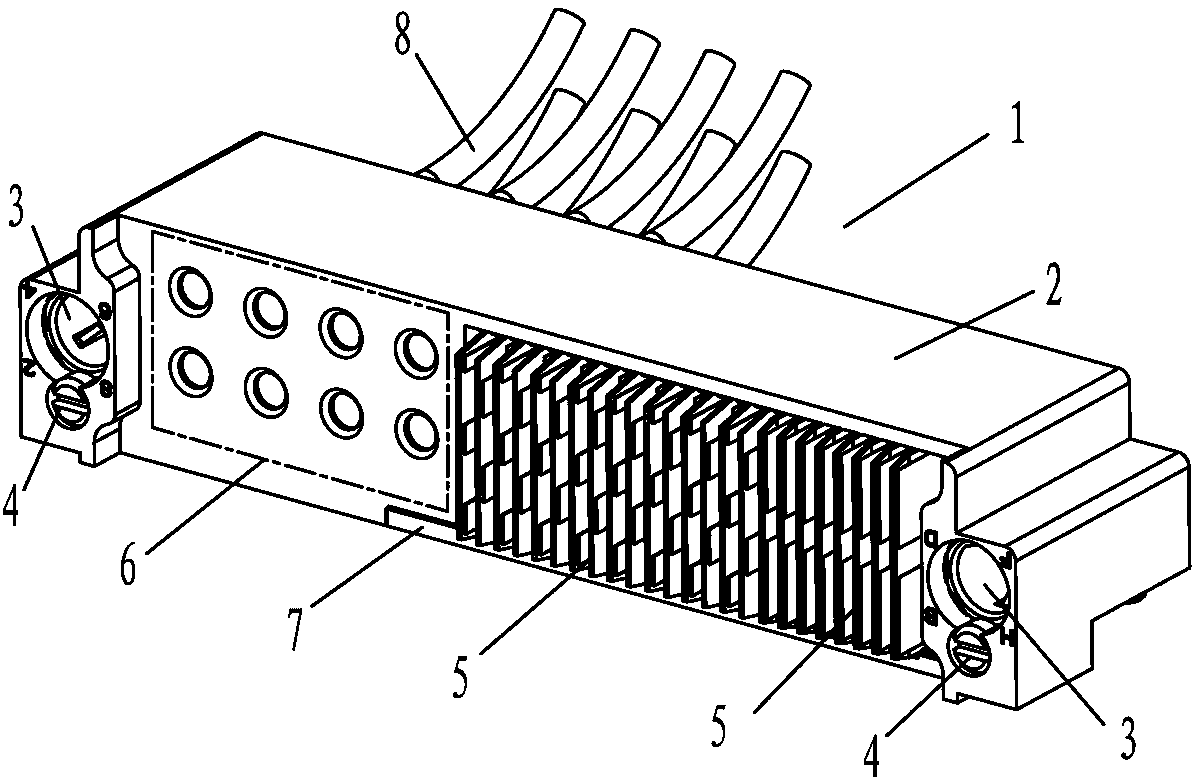

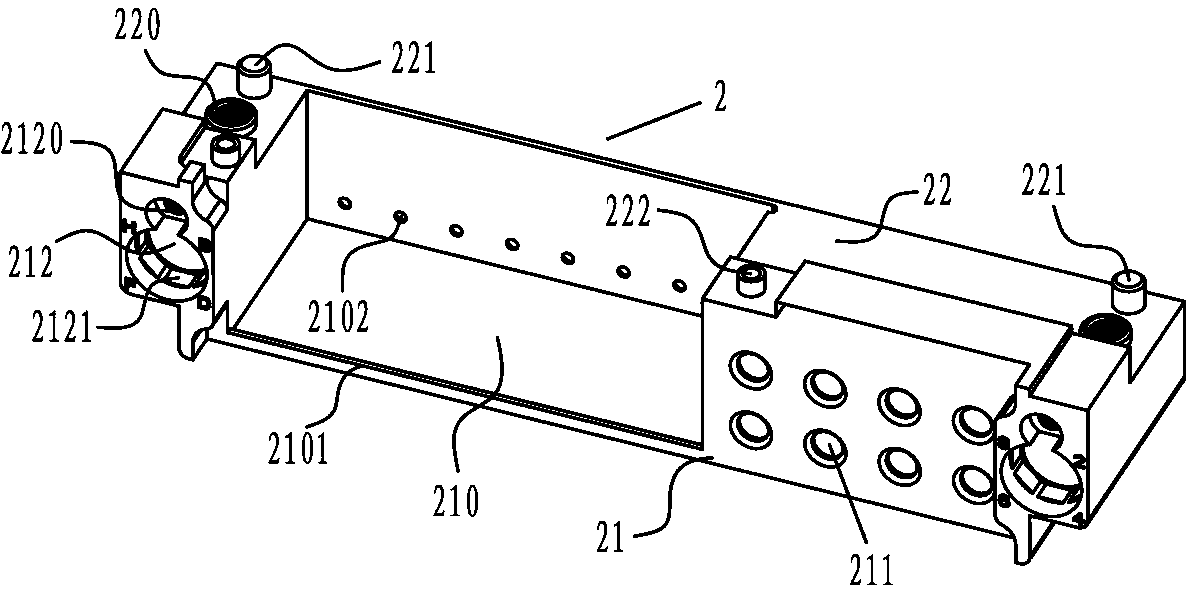

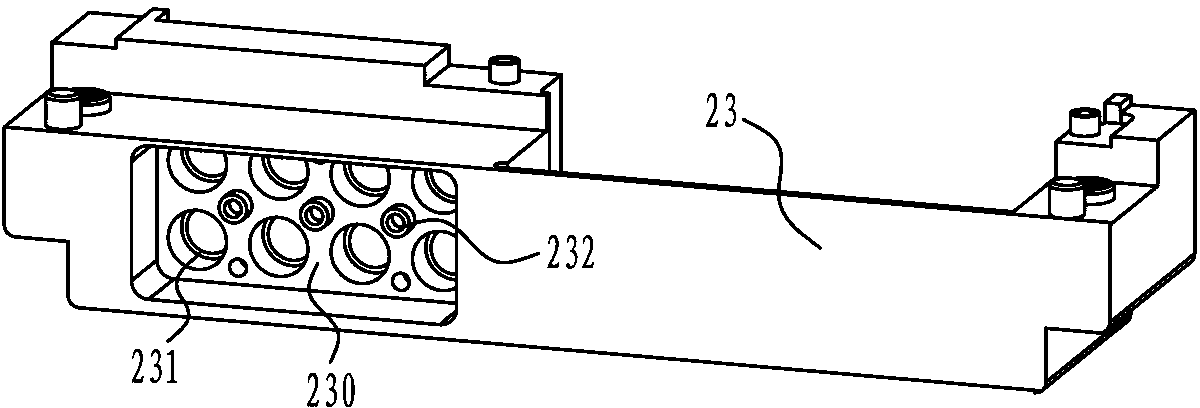

[0023] refer to figure 1 , the present invention 1 is composed of a housing part, a guide part, a module part and a functional terminal part, wherein the housing part includes: a fixed cover 2 formed by machining and a clamping plate 7 for fixing; The guide part includes a locking screw 4 for fixing and a guide ring 3 for positioning and guiding. They are fixed on both ends of the fixed cover 2 and located on both sides of the connector module, which can realize the connection between the connector module and the guide. High relative position relationship between components; the module part includes: digital module 5 and functional module 6, wherein the digital module 5 is fixed in the inner cavity of the fixed cover 2 through the clamp plate 7; the functional module 6 includes reinforcement units and accessories unit, the reinforcement un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com