Chemical plating activation process for fabric by using supercritical carbon dioxide fluid

A carbon dioxide, supercritical technology, used in liquid chemical plating, metal material coating process, textiles and papermaking, etc., to achieve easy mass production, simple process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

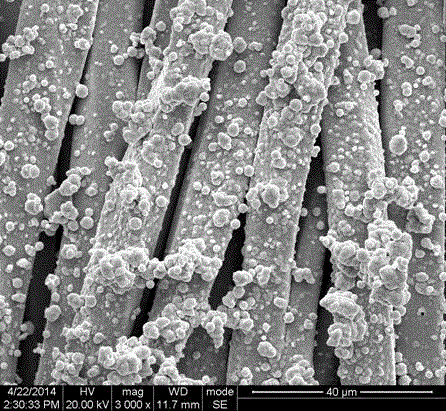

[0040] The polyester fabrics with a size of 5cm×5cm were ultrasonically cleaned with acetone and ethanol for 30min respectively, and the fabrics were taken out, washed in deionized water, and dried in an oven; the cleaned polyester fabrics and nickel acetylacetonate were placed in a supercritical fluid device, Under the condition of 90℃, 10MPa, treated for 20min, take out the polyester fabric, after ultrasonic treatment in 5g / L sodium borohydride for 5min, put it into the electroless copper plating solution, the plating solution contains copper sulfate 14g / L, ethylenediaminetetramine Disodium acetate 20g / L, glyoxylic acid 12g / L, potassium ferrocyanide 10mg / L, heated in a water bath at 70°C, and reacted for 20min; finally, the cloth sample was taken out, washed repeatedly with deionized water, and dried in an oven at 80°C.

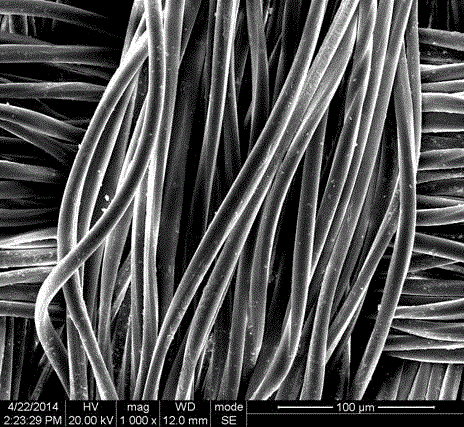

[0041] The surface morphology and conductive energy of polyester fabric after supercritical fluid activation treatment and electroless copper plating are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com