Polymer/graphene foamed material with electromagnetic shielding performance, and preparation method and application thereof

A foaming material and electromagnetic shielding technology, applied in the field of polymer/graphene foaming material and preparation, can solve problems such as processing and foaming process difficulties, and achieve easy industrialized mass production, good market application prospects, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 0.63 g of graphene into 100 mL of DMF, and ultrasonically disperse for 5 minutes. Then, 15 g of polyurethane particles were added therein, and after high-speed stirring and dissolution, the mixed solution was poured into the scraping groove of a scraper to coat a film on a clean glass plate. After completion, put it in a constant temperature and humidity oven with a temperature of 25° C. and a relative humidity of 78% for 5 hours. Finally, the obtained material was placed in a vacuum oven for drying treatment to obtain a polyurethane / graphene microfoaming film with a graphene content of 4wt.%.

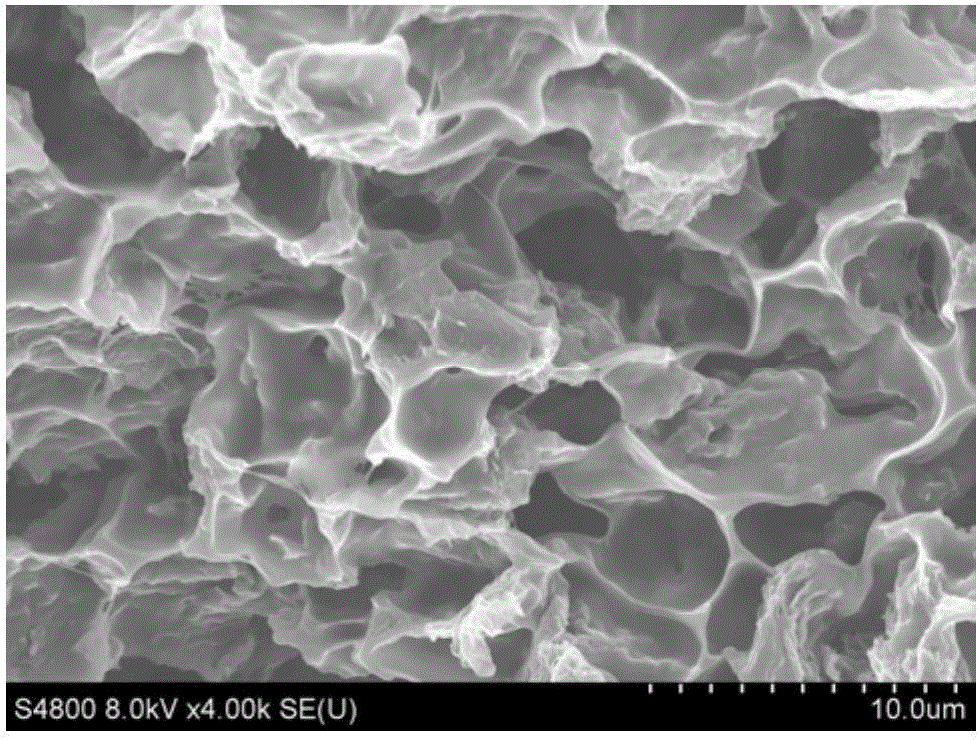

[0035] In addition, polyurethane / graphene microfoamed films with graphene content of 8wt.% and 16wt.% were also prepared by the same method. Wherein, graphene content is the cross-section morphology figure of the polyurethane / graphene microfoam film of 8wt.%. figure 1 As shown, the average cell size is about 5 μm. In addition, the thickness and cell morphology of the ...

Embodiment 2

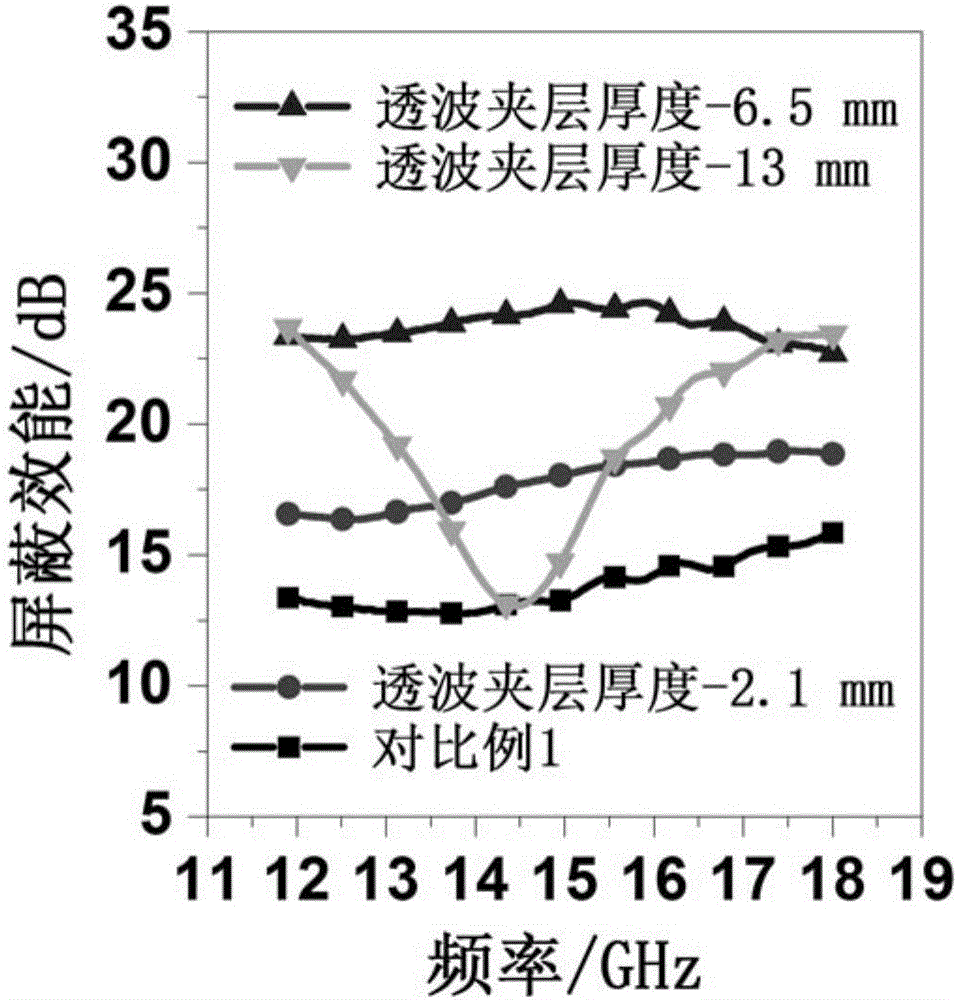

[0041] The materials used in this example are polyurethane / graphene microfoaming films and polystyrene foams with graphene content of 8wt.% and 16wt.% prepared in Example 1.

[0042] Three kinds of single-layer polystyrene foams with a thickness of 2.1, 6.5 and 13.0 mm were sandwiched between the above two single-layer polyurethane / graphene micro-foamed films, and the layers were bonded with glue to form three kinds of sandwiches. Structural all-in-one polymer / graphene foams.

Embodiment 3

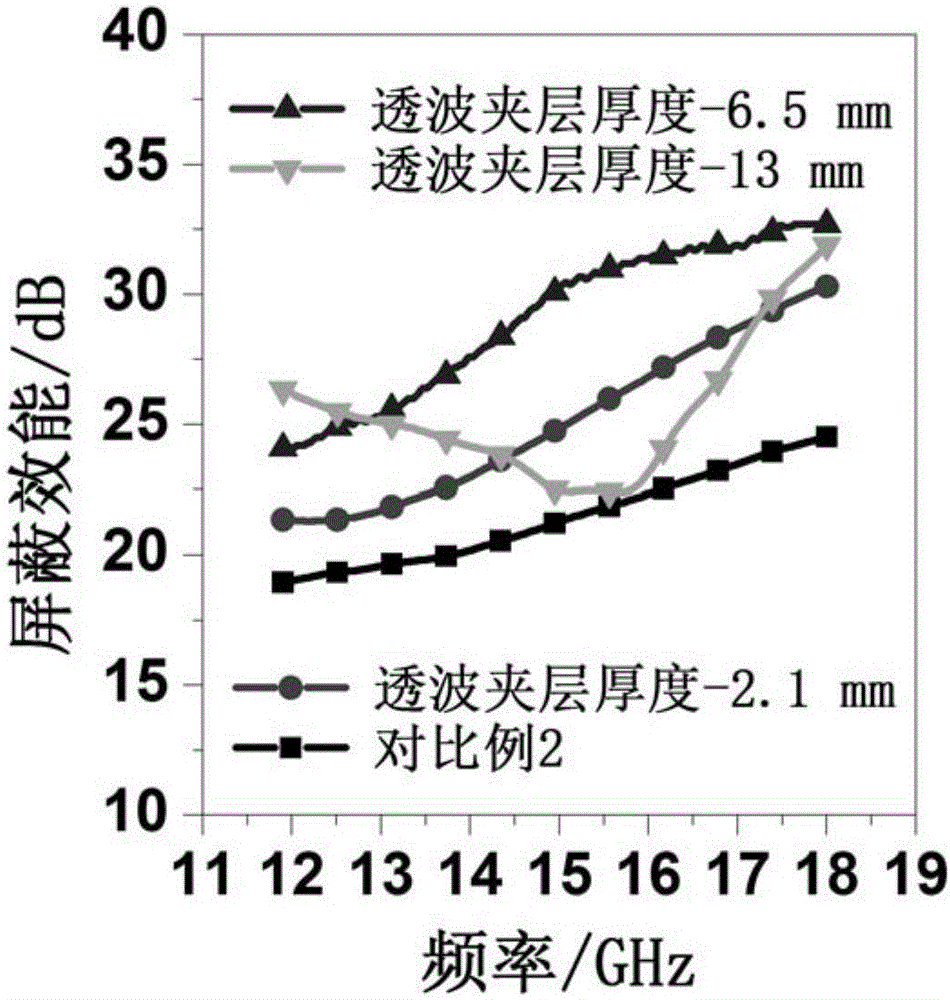

[0048] The materials used in this example are the polyurethane / graphene microfoaming film and polystyrene foam with a graphene content of 8wt.% prepared in Example 1.

[0049] The specific method is that a layer of polystyrene foam with a thickness of 6.5mm is sandwiched between two layers of polyurethane / graphene micro-foamed films with a graphene content of 8wt.%, and the layers are bonded with glue to form a An integrated polymer / graphene foam with a sandwich structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com