Electroconductive woodceramic powder and its manufacturing method

A technology of wood ceramics and conductive powder, which is applied in the field of wood ceramic materials and its preparation, can solve the problems of high brittleness and easy cracking, and achieve the effects of improving shielding effect, reducing costs and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

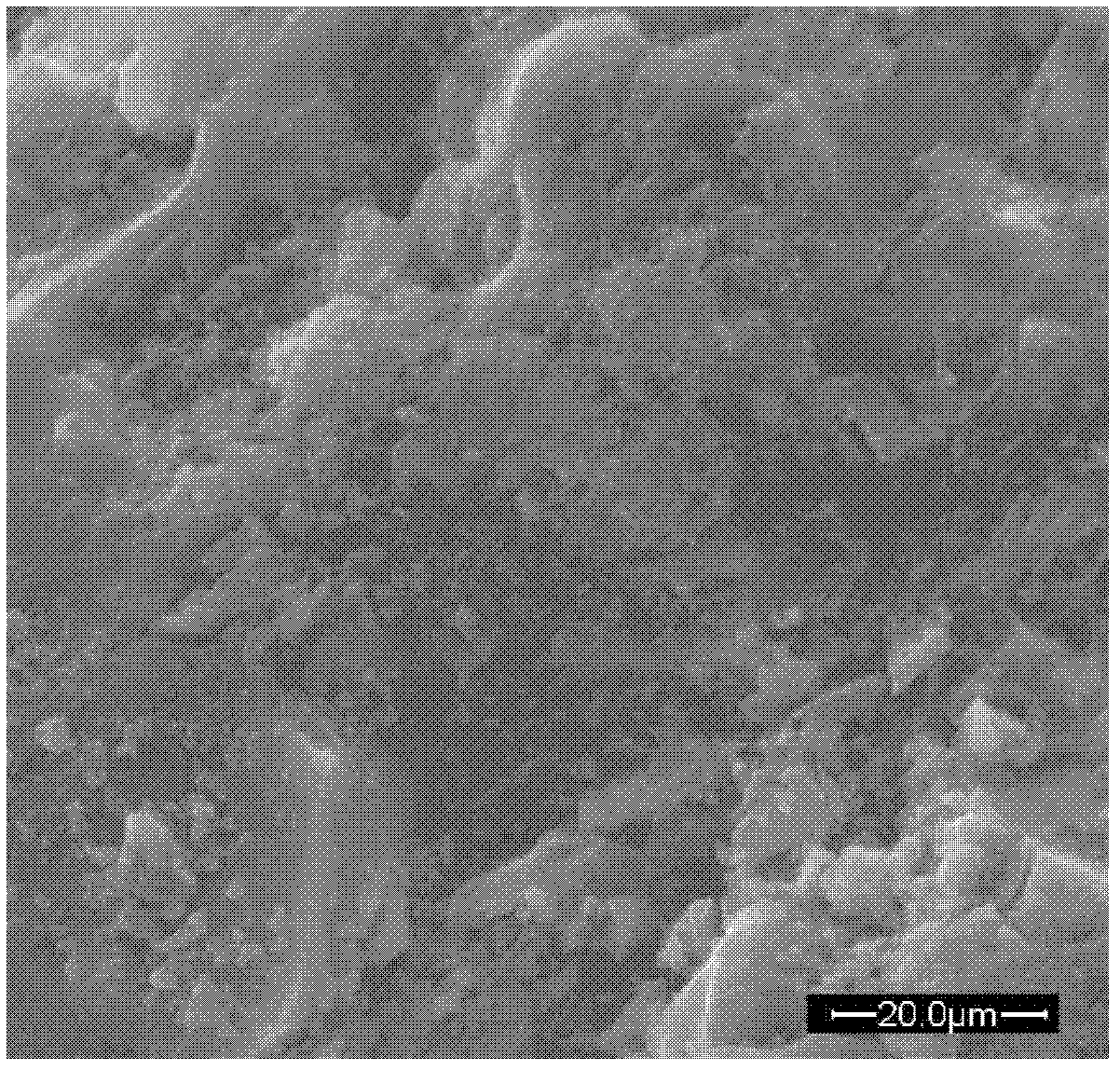

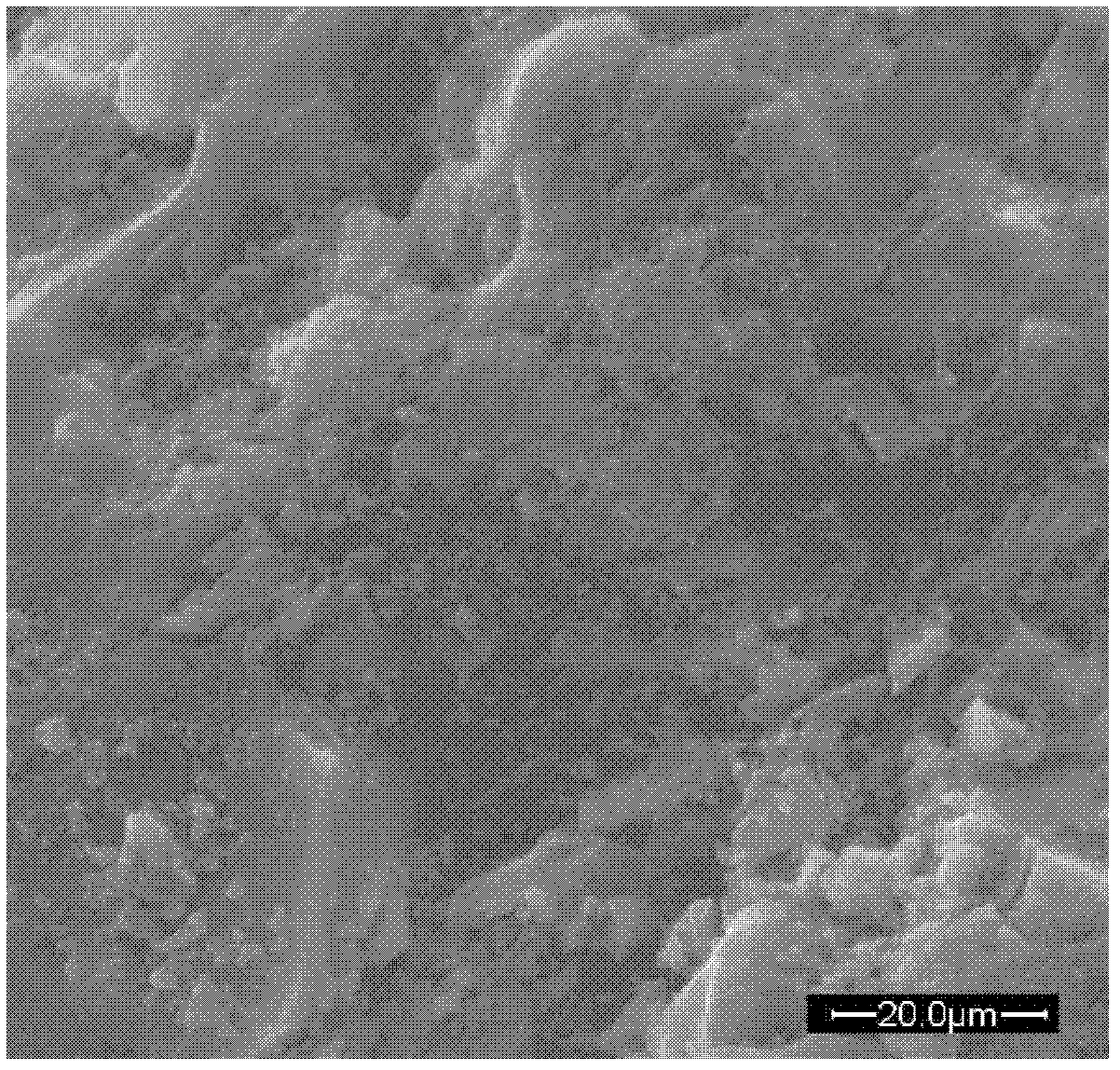

[0021] Specific embodiment one: a kind of conductive wood ceramic powder of this embodiment takes wood ceramic powder as the core body, and the conductive powder body of a layer of metal film is chemically plated on the surface of the core body, and the adhesion amount of metal is the quality of wood ceramic powder. 1% to 50%; the metal is nickel, iron or cobalt.

[0022] The conductive wood ceramic powder of this embodiment is a wood ceramic powder / metal composite core-shell type composite material. The combination of metal and porous wood ceramic powder can effectively absorb electromagnetic waves, especially for broadband 100KHz-30000MHz electromagnetic waves. absorb. It can be used as a conductive filler for the preparation of electromagnetic shielding materials. This conductive filler is easy to disperse evenly and can establish a good conductive network. The porous structure of wood ceramics can make electromagnetic waves reflect and absorb multiple times inside it, resu...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that: the amount of metal attached is 5% to 40% of the mass of the wood ceramic powder. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the preparation method of the wood ceramic powder as the core is carried out as follows: the biomass raw material is dried at a temperature of 30 ° C to 100 ° C to Dry, then sinter the dried biomass raw material at a temperature of 600°C to 2500°C for 2h to 10h in a vacuum environment or under the protection of an inert gas, and then use a ball mill to crush it to a particle size of 0.1μm to 200μm to obtain wood ceramic powder as a core wherein the biomass raw material is wood, walnut shell, bamboo, rice husk, coffee grounds, tea grounds, tobacco rods, bagasse, lignin or waste paper. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com