Preparation method of electromagnetic shielding honeycomb core material

An electromagnetic shielding, honeycomb core material technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of coating peeling, affecting shielding effect, heavy weight, etc., to achieve light structure and function Quantification, maintaining good mechanical properties, and integrating structure and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

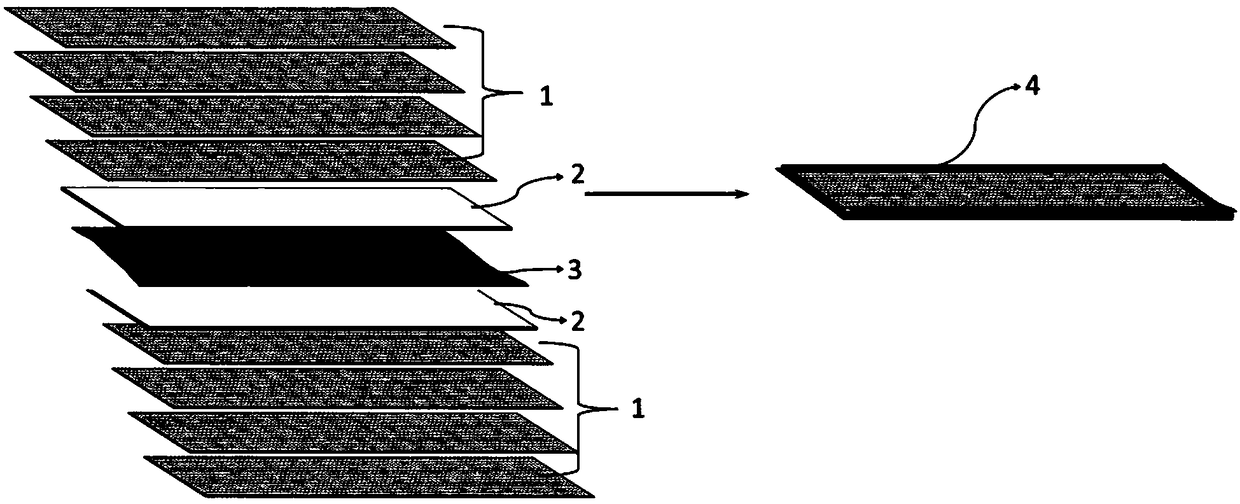

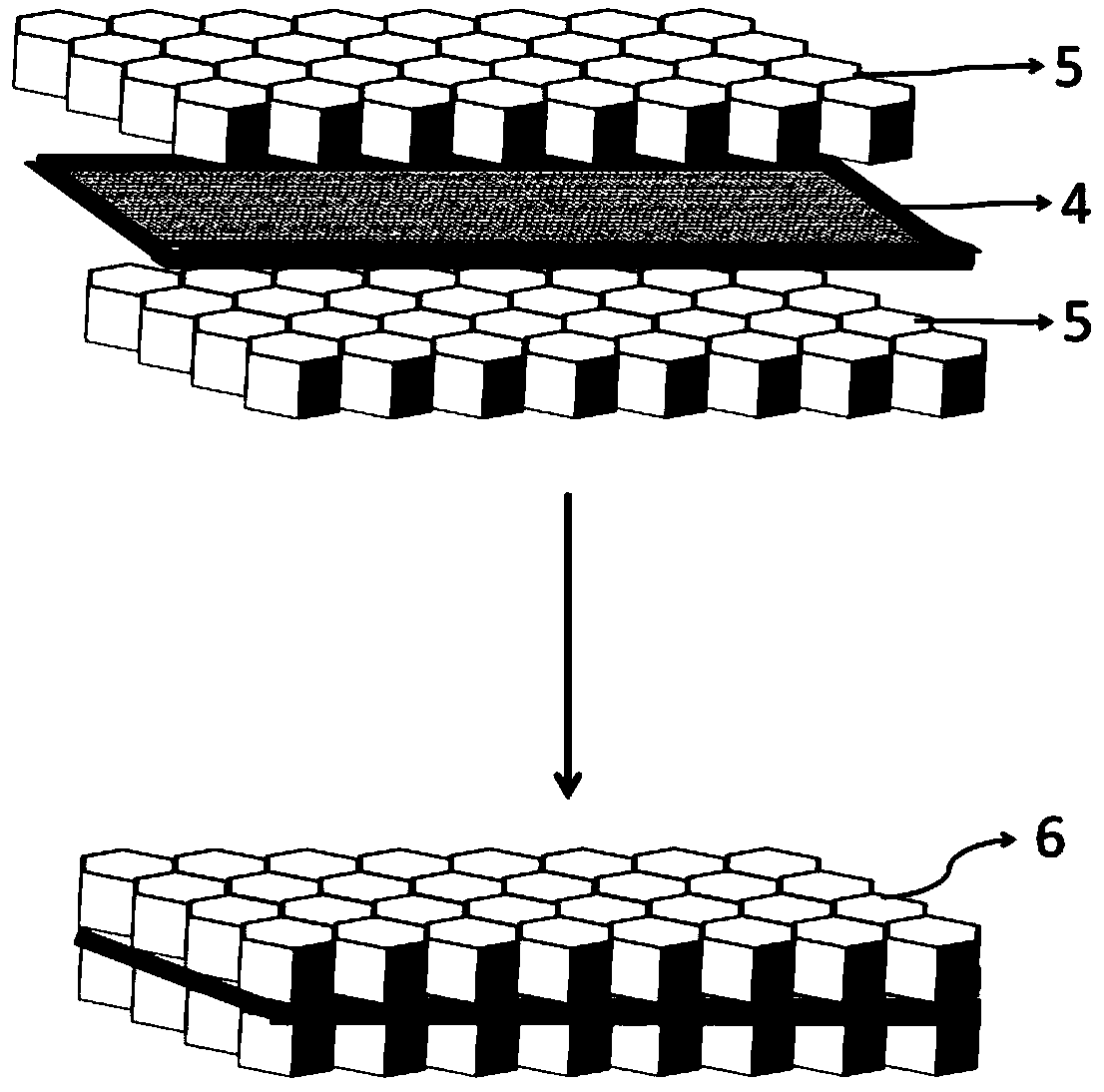

[0033] A kind of manufacture technology of graphene / ferrite electromagnetic shielding interlayer honeycomb core material, it is characterized in that, design and preparation step ( figure 1 , figure 2 )as follows:

[0034] (1) 0.5-5g graphene, 1000-2200g deionized water, 50-600g ferric chloride, 30-200g ferrous chloride, 10-100mL ammonia water;

[0035] Add the above mass parts of graphene into deionized water, and disperse for 0.5-5 hours at a temperature of 30-80°C using an ultrasonic disperser; add the above mass parts of ferric chloride and ferrous chloride into the graphene suspension , continue to stir in a water bath at 30-80°C for 10-60 minutes; then add 10-100g of the above-mentioned mass fraction of ammonia water, and continue to stir in a water bath for 10-60 minutes; use deionized water to repeatedly wash the graphene / ferrite particles until the graphene / The ferrite suspension is neutral.

[0036] (2) Using a magnet to separate the graphene / ferrite particles f...

Embodiment 2

[0041] A kind of manufacture technology of graphene / ferrite electromagnetic shielding interlayer honeycomb core material, it is characterized in that, design and preparation step ( figure 1 , figure 2 )as follows:

[0042] (1) 0.5-5g graphene, 1000-2200g deionized water, 50-600g ferric chloride, 30-200g ferrous chloride, 10-100mL ammonia water;

[0043] Add the above mass parts of graphene into deionized water, and disperse for 0.5-5 hours at a temperature of 30-80°C using an ultrasonic disperser; add the above mass parts of ferric chloride and ferrous chloride into the graphene suspension , continue to stir in a water bath at 30-80°C for 10-60 minutes; then add 10-100g of the above-mentioned mass fraction of ammonia water, and continue to stir in a water bath for 10-60 minutes; use deionized water to repeatedly wash the graphene / ferrite particles until the graphene / The ferrite suspension is neutral.

[0044] (2) Using a magnet to separate the graphene / ferrite particles f...

Embodiment 3

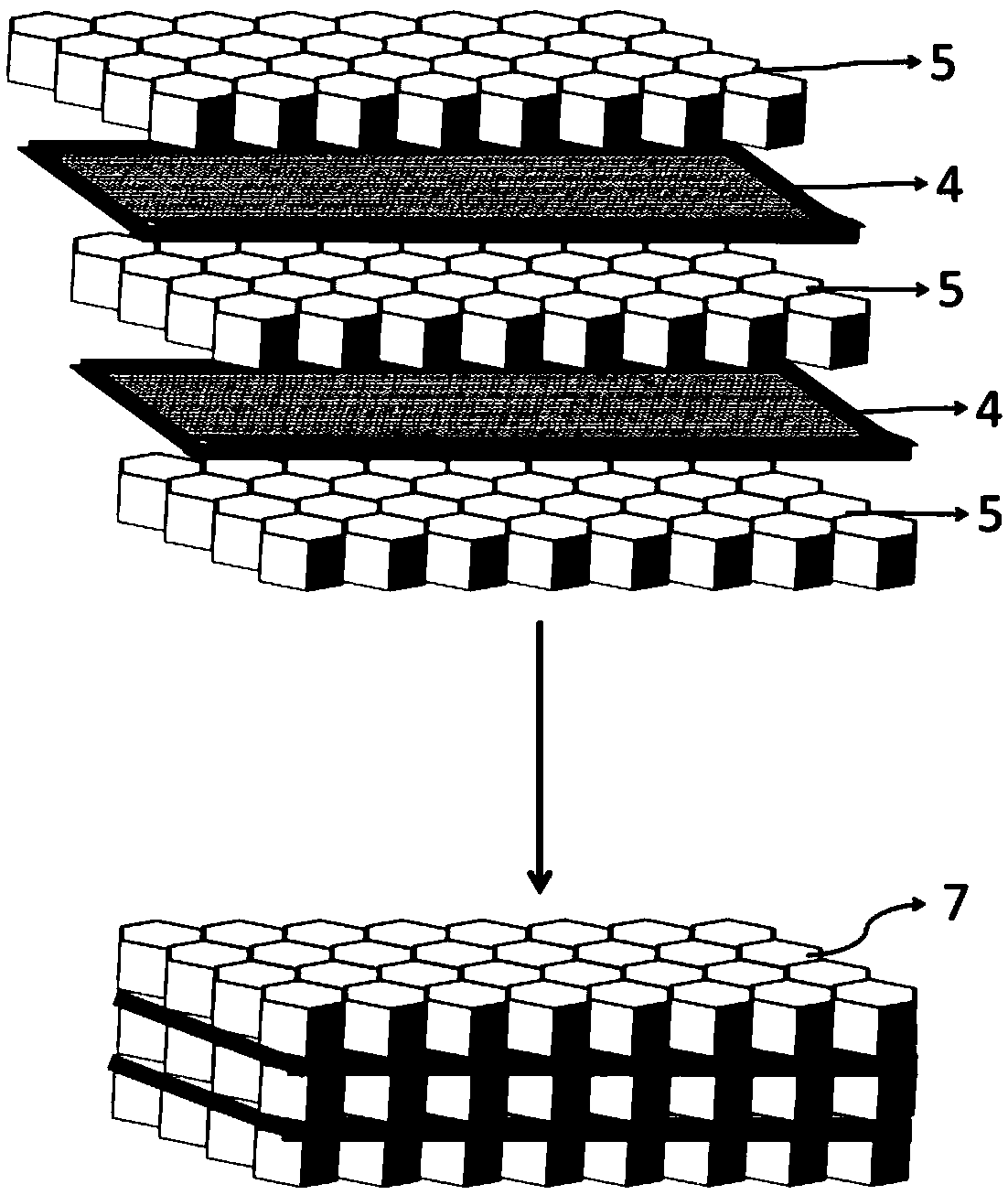

[0049] Similar to embodiment 1, a kind of manufacturing technology of graphene / ferrite electromagnetic shielding foam is characterized in that, design and preparation steps ( Figure 1-3 )as follows:

[0050] A kind of manufacture technology of graphene / ferrite electromagnetic shielding interlayer honeycomb core material, it is characterized in that, design and preparation step ( figure 1 , figure 2 )as follows:

[0051] (1) 0.5-5g graphene, 1000-2200g deionized water, 50-600g ferric chloride, 30-200g ferrous chloride, 10-100mL ammonia water;

[0052] Add the above mass parts of graphene into deionized water, and disperse for 0.5-5 hours at a temperature of 30-80°C using an ultrasonic disperser; add the above mass parts of ferric chloride and ferrous chloride into the graphene suspension , continue to stir in a water bath at 30-80°C for 10-60 minutes; then add 10-100g of the above-mentioned mass fraction of ammonia water, and continue to stir in a water bath for 10-60 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com