A method of a modified silicon -based polymer to prepare the structure function of integrated coating

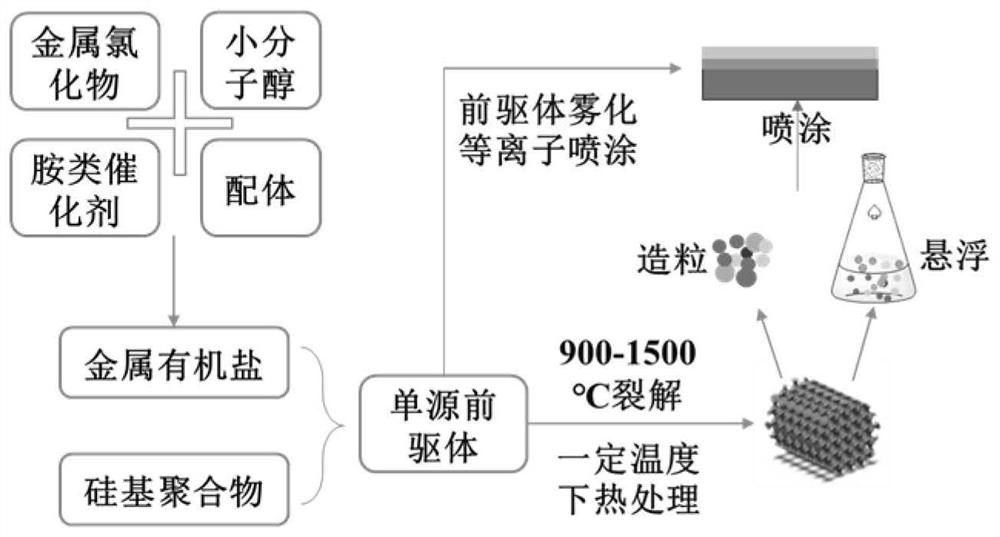

A technology of silicon-based polymers and polymers is applied to the preparation of structural-functional integration materials. . , a modified silicon-based polymer in the field of integrated structure and function, which can solve the problems that are difficult to greatly improve the ablation resistance and microwave absorption performance, and achieve the effects of strong designability, high efficiency, and great development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

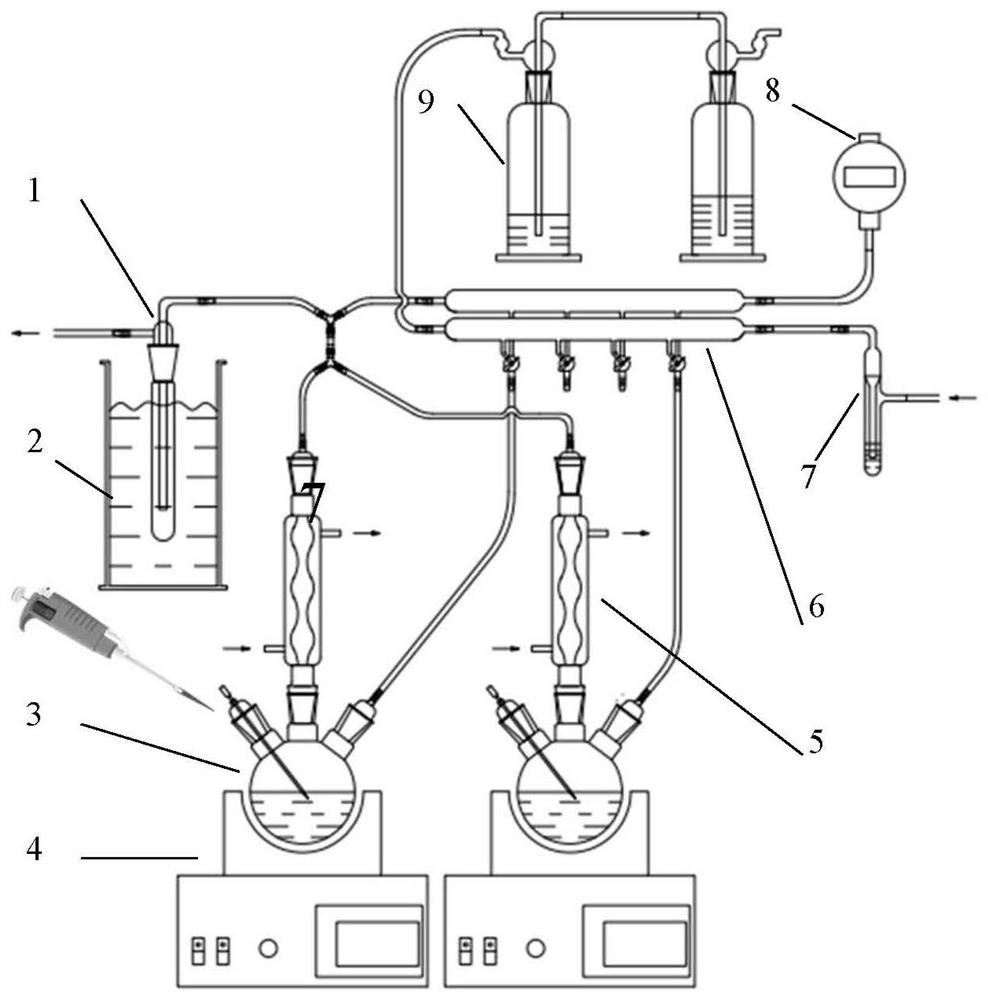

[0030] First, weigh 3.5g of polycarbosilane into a three-necked flask, add magnetron and zeolite, apply a certain amount of vacuum grease to each grinding joint of the schlenk equipment, connect the equipment, and place the Dewar flask in the equipment Under the cold sink, put liquid nitrogen in the Dewar bottle for sealing, then turn on the vacuum pump to vacuum to remove the air in the equipment and the water vapor in the glass wall, until the vacuum degree is in the range of -0.9~-1.0mpa, close the vacuum pump Carry out pressure maintenance to ensure good air tightness of the equipment. At this time, turn on the argon switch again, and adjust the argon flow rate to select an appropriate flow rate according to the gas output of the bubbler to ensure stable airflow. At this time, slowly open the valve on the double-row pipe to the vacuum side until the vacuum degree in the three-neck bottle is consistent and stable with the vacuum degree at other positions of the equipment, a...

Embodiment 2

[0035] First, weigh 4 mol of hafnium chloride and 1 mol of tantalum chloride into a three-necked flask, add magnetron and zeolite, apply a certain amount of vacuum grease to the ground joints of the schlenk equipment, and connect the equipment. Put it under the cold sink in the equipment, and put liquid nitrogen into the Dewar flask for sealing, and then turn on the vacuum pump to vacuum to remove the air in the equipment and the water vapor in the glass wall until the vacuum degree is -0.9~-1.0mpa Turn off the vacuum pump to keep the pressure in the range to ensure good air tightness of the equipment. At this time, turn on the argon switch again, and adjust the argon flow rate to select an appropriate flow rate according to the gas output of the bubbler to ensure stable airflow. At this time, slowly open the valve on the double-row pipe to the vacuum side until the vacuum degree in the three-neck bottle is consistent and stable with the vacuum degree at other positions of the...

Embodiment 3

[0040] First, weigh 0.4mol zirconium acetylacetonate, 0.1mol titanium acetylacetonate, and 0.3mol polycarbosilane, dissolve them in xylene, pour them into a three-necked flask, add magnetron and zeolite, and smear the ground joints of the schlenk equipment. A certain amount of vacuum grease and the equipment are connected, the Dewar flask is placed under the cold sink in the equipment, and the Dewar flask is filled with liquid nitrogen for sealing, and then the vacuum pump is turned on to remove the air and glass wall in the equipment. When the vacuum degree is in the range of -0.9~-1.0mpa, turn off the vacuum pump to maintain the pressure to ensure good air tightness of the equipment. At this time, turn on the argon switch again, and adjust the argon flow rate to select an appropriate flow rate according to the gas output of the bubbler to ensure stable airflow. At this time, slowly open the valve on the double-row pipe to the vacuum side until the vacuum degree in the three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com