Device for separately refluxing nitrifying liquid and sludge

A backflow device and nitrifying solution technology, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

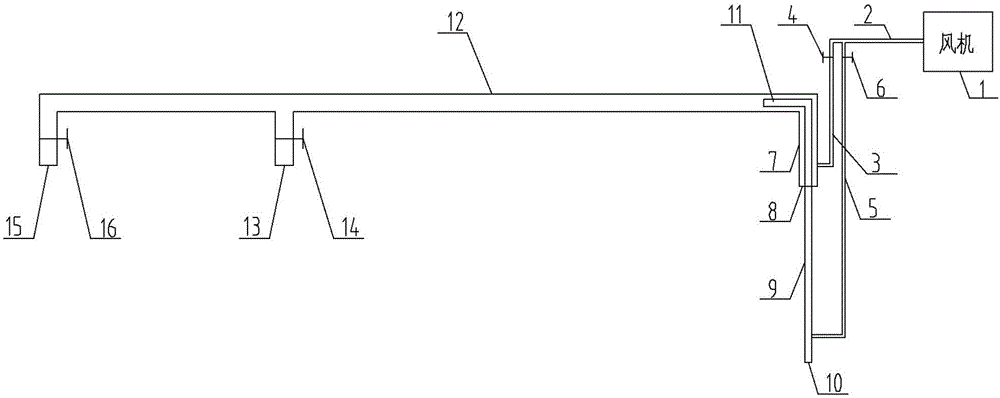

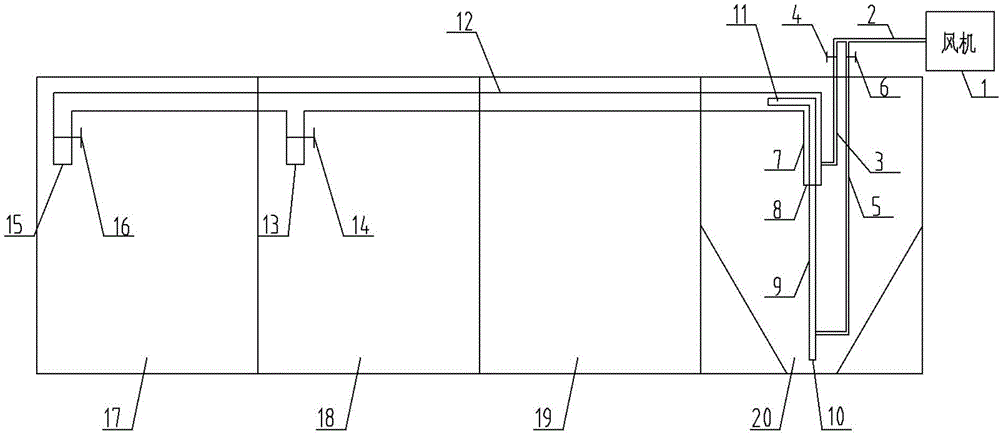

[0027] figure 1 Shown is a specific embodiment of the nitrifying liquid sludge return device respectively, the device mainly includes a nitrifying liquid riser 7 and a sludge riser 9, wherein the nitrifying liquid riser 7 and the sludge riser 9 are vertically inserted into the In the settling area 20, and the nitrification liquid riser sleeve 7 is arranged on the outside of the sludge riser 9; the nitrification liquid riser 7 has a liquid lift section extending from top to bottom to the supernatant position of the biochemical tank sedimentation area 20, And the pumping device for sucking the nitrifying liquid from the nitrifying liquid lifting pipe water inlet 8 of the liquid lifting section; the sludge lifting pipe 9 has a mud lifting section stretching from top to bottom to the bottom of the sedimentation zone 20, and lifts from the mud A sludge pumping device for sucking sludge through the sludge lifter inlet 10 of the sludge lifter section, wherein the sludge lifter inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com