Pipeline dredging system

A technology for pipelines and water pipes, applied in the field of pipeline dredging systems, can solve problems such as difficult dredging, and achieve the effects of improving dredging effect, improving dredging efficiency and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

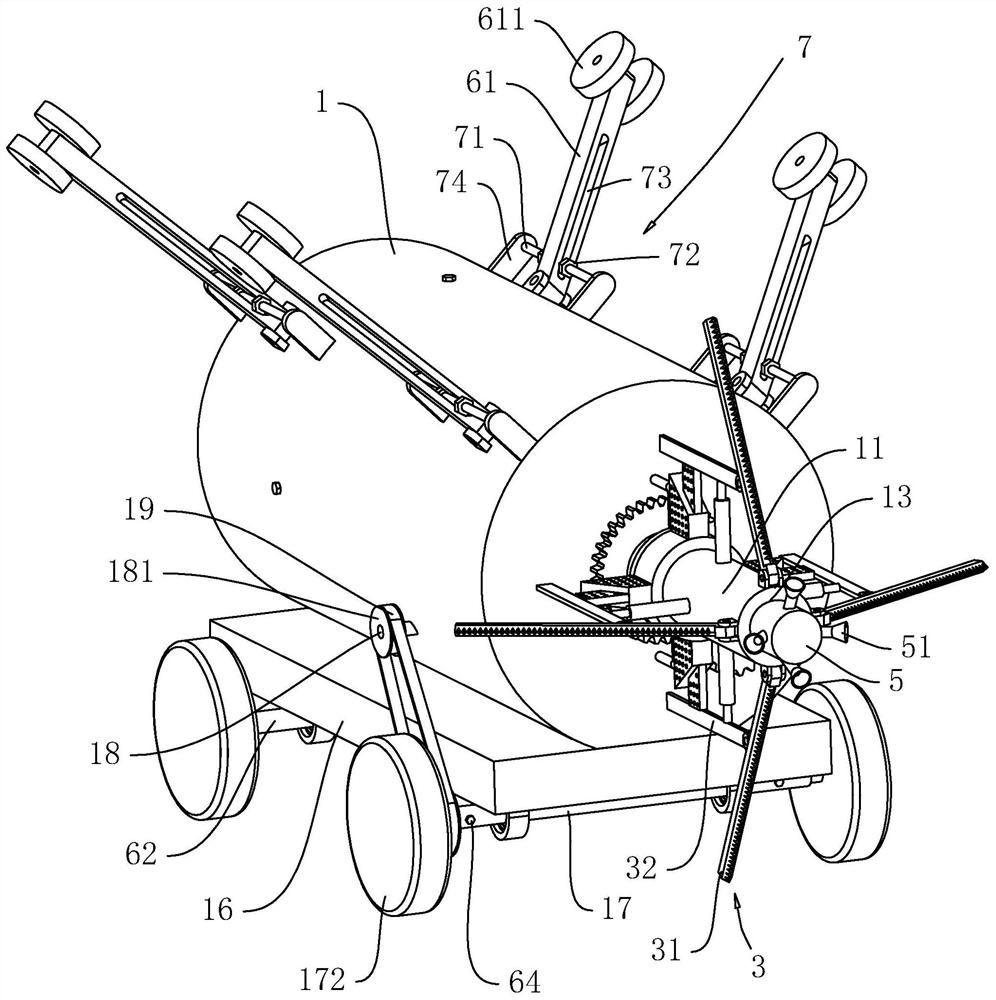

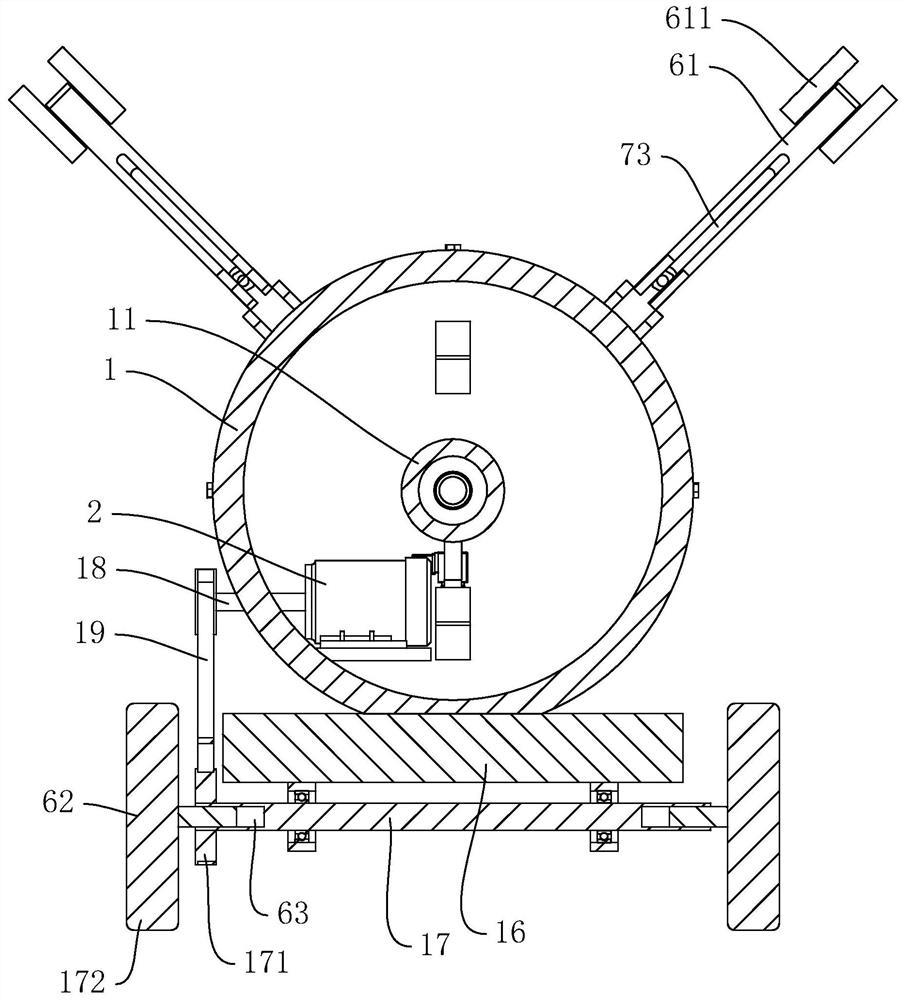

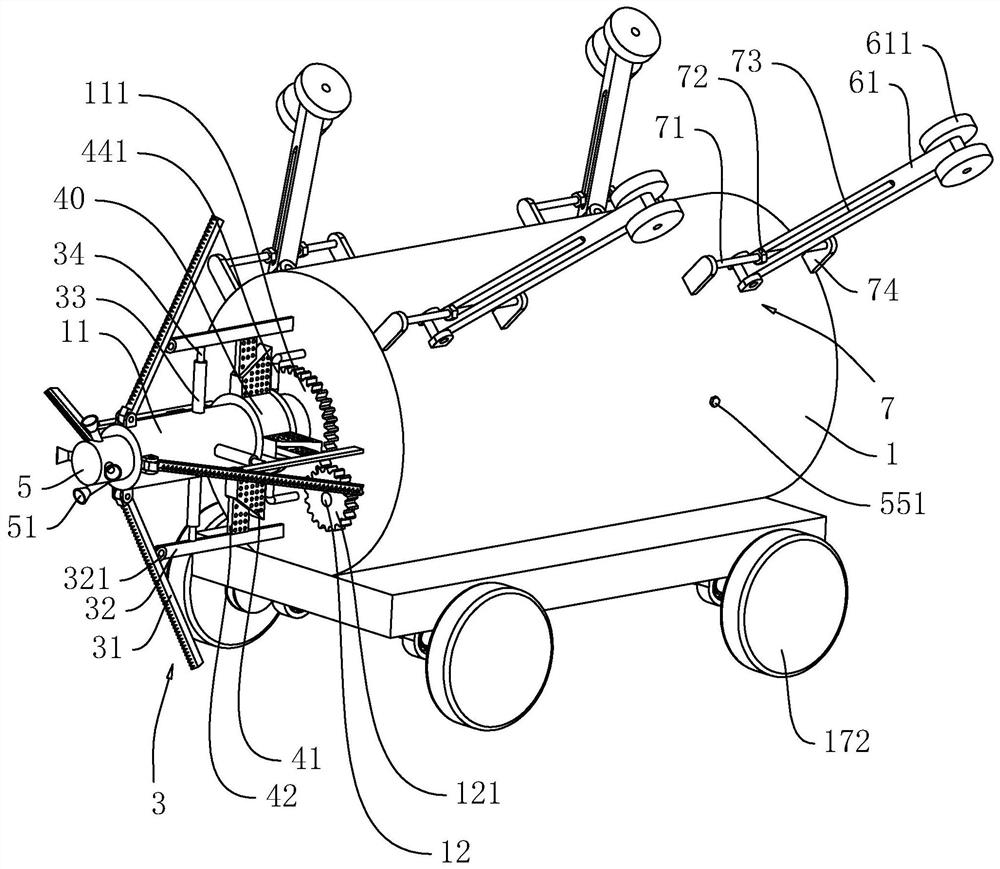

[0038] The following is attached Figure 1-5 The application is described in further detail.

[0039] The embodiment of the present application discloses a pipeline dredging system. Such as figure 1 with figure 2 The dredging system includes a drill barrel 1, the outer wall of the drill barrel 1 is provided with a chassis 16, the outer wall of the drill barrel 1 is provided with a chassis 16, and the side of the chassis 16 away from the drill barrel 1 is rotationally connected with two parallel rotating shafts 17, and the axis of the rotating shaft 17 is Perpendicular to the axis of the drill barrel 1, both ends of each rotating shaft 17 are provided with telescopic grooves 63 extending axially, each telescopic groove 63 is inserted with a telescopic column 62, and the telescopic column 62 is located outside the rotating shaft 17. One end is coaxially provided with a walking wheel 172, and the rotating shaft 17 is threadedly connected with an adjusting screw 64, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com