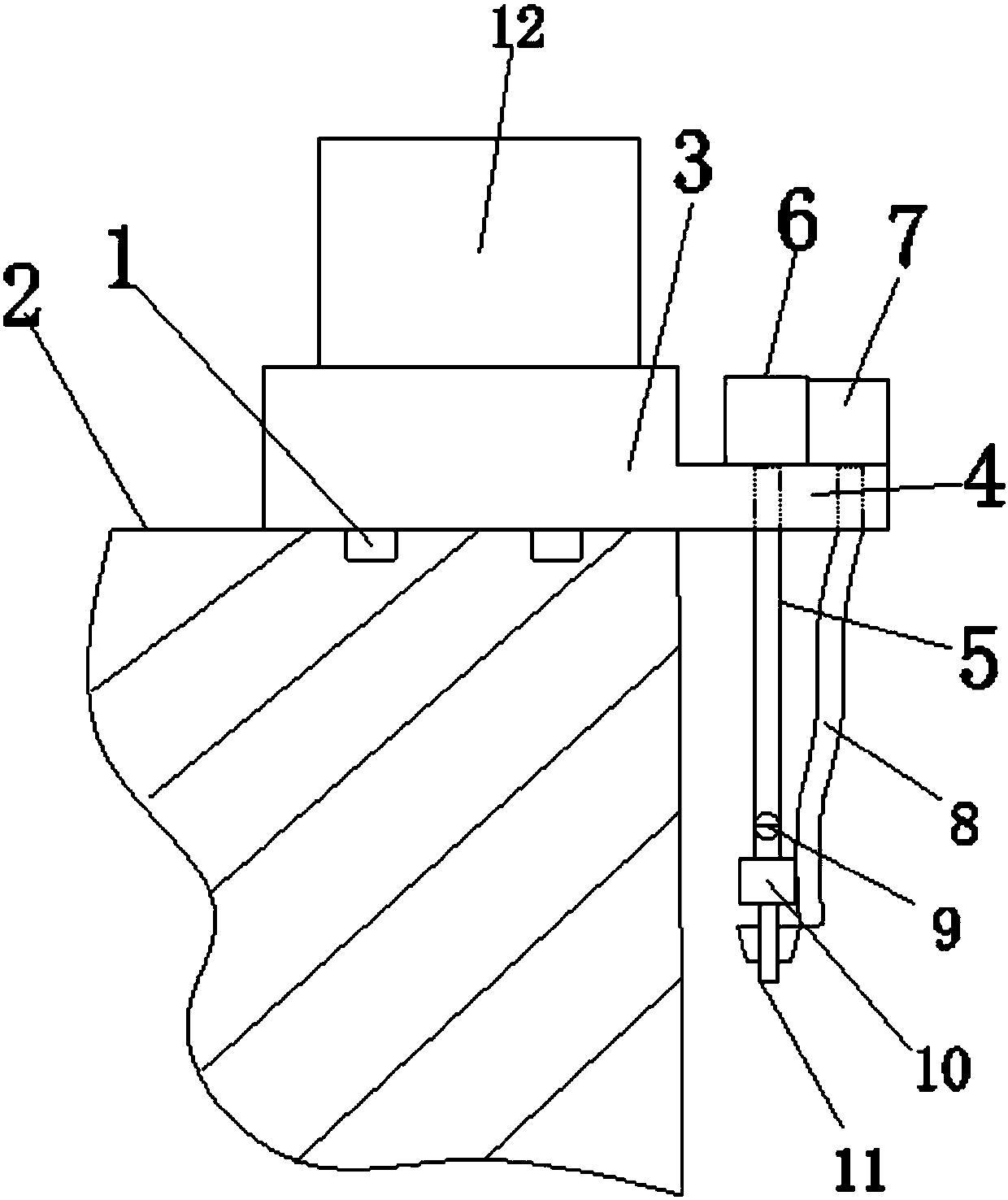

Wharf bottom desilting machine and method

A wharf and machine tool technology, applied in the wharf field, can solve problems such as low return on investment, low work efficiency, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

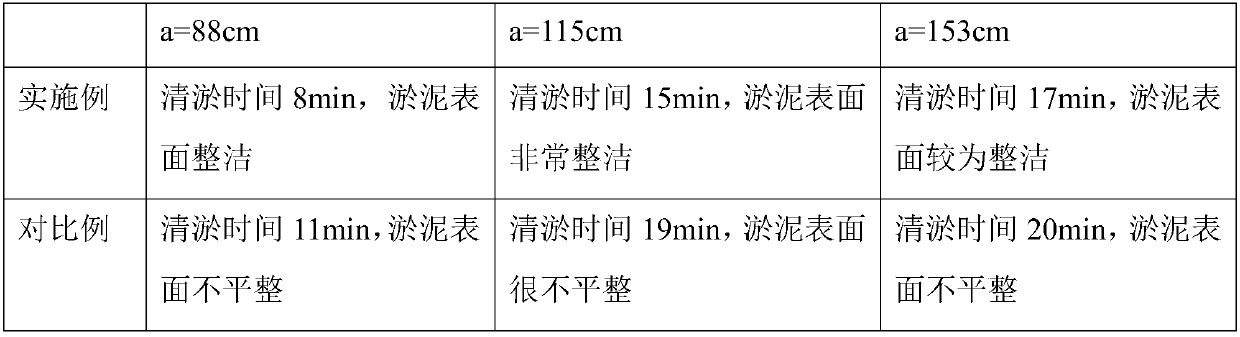

Embodiment 1

[0045]Embodiment 1 obtains the silt height c of 88cm at the position to be dredged, which is the difference between a and b, which is 38cm, and calculates the volume v of the silt to be removed according to the silt height, and v equals the work of the dredging parts The product of area s and c, s is 1m 2 , then v is 0.38m 3 , move the support platform to the position to be dredged through the cooperation of the slide rail and the chute, and fix it;

[0046] When the hydraulic cylinder is turned on, the dredging parts will drop by 88cm driven by the telescopic rod; when the hydraulic cylinder is turned off, the dredging parts will stop falling;

[0047] Turn on the motor, the agitating fins start to rotate, and at the same time turn on the high-pressure water pump, the water flow is sprayed out through the water pipe and the nozzle, after a predetermined lag time, the mud pump is turned on, and the sludge enters the mud storage tank through the mud delivery pipe;

[0048] Th...

Embodiment 2

[0052] Obtain the silt height c of 115cm at the position to be dredged, which is the difference between a and b, which is 65cm, and calculate the volume v of the silt to be removed according to the silt height, and v is equal to the working area s and The product of c, s is 1m 2 , then v is 0.65m 3 , move the support platform to the position to be dredged through the cooperation of the slide rail and the chute, and fix it;

[0053] When the hydraulic cylinder is turned on, the dredging part will drop 115cm under the drive of the telescopic rod; when the hydraulic cylinder is turned off, the dredging part will stop falling;

[0054] Turn on the motor, the agitating fins start to rotate, and at the same time turn on the high-pressure water pump, the water flow is sprayed out through the water pipe and the nozzle, after a predetermined lag time, the mud pump is turned on, and the sludge enters the mud storage tank through the mud delivery pipe;

[0055] The hydraulic cylinder i...

Embodiment 3

[0059] Obtain the silt height c of 153cm at the position to be dredged, which is the difference between a and b, which is 103cm, and calculate the volume v of the silt to be removed according to the silt height, and v is equal to the working area s and The product of c, s is 1m 2 , then v is 1.03m 3 , move the support platform to the position to be dredged through the cooperation of the slide rail and the chute, and fix it;

[0060] When the hydraulic cylinder is turned on, the dredging parts will drop 153cm under the drive of the telescopic rod, and when the hydraulic cylinder is turned off, the dredging parts will stop falling;

[0061] Turn on the motor, the agitating fins start to rotate, and at the same time turn on the high-pressure water pump, the water flow is sprayed out through the water pipe and the nozzle, after a predetermined lag time, the mud pump is turned on, and the sludge enters the mud storage tank through the mud delivery pipe;

[0062] The hydraulic cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com