River and lake contaminated bottom sediment ecological desilting ship

A technology for polluting sediment and dredging boats, which is applied in the direction of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., and can solve the problems of plant damage, low cleaning efficiency, and inability to protect plants. Achieve the effects of protecting plants, increasing the effective range, and improving dredging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

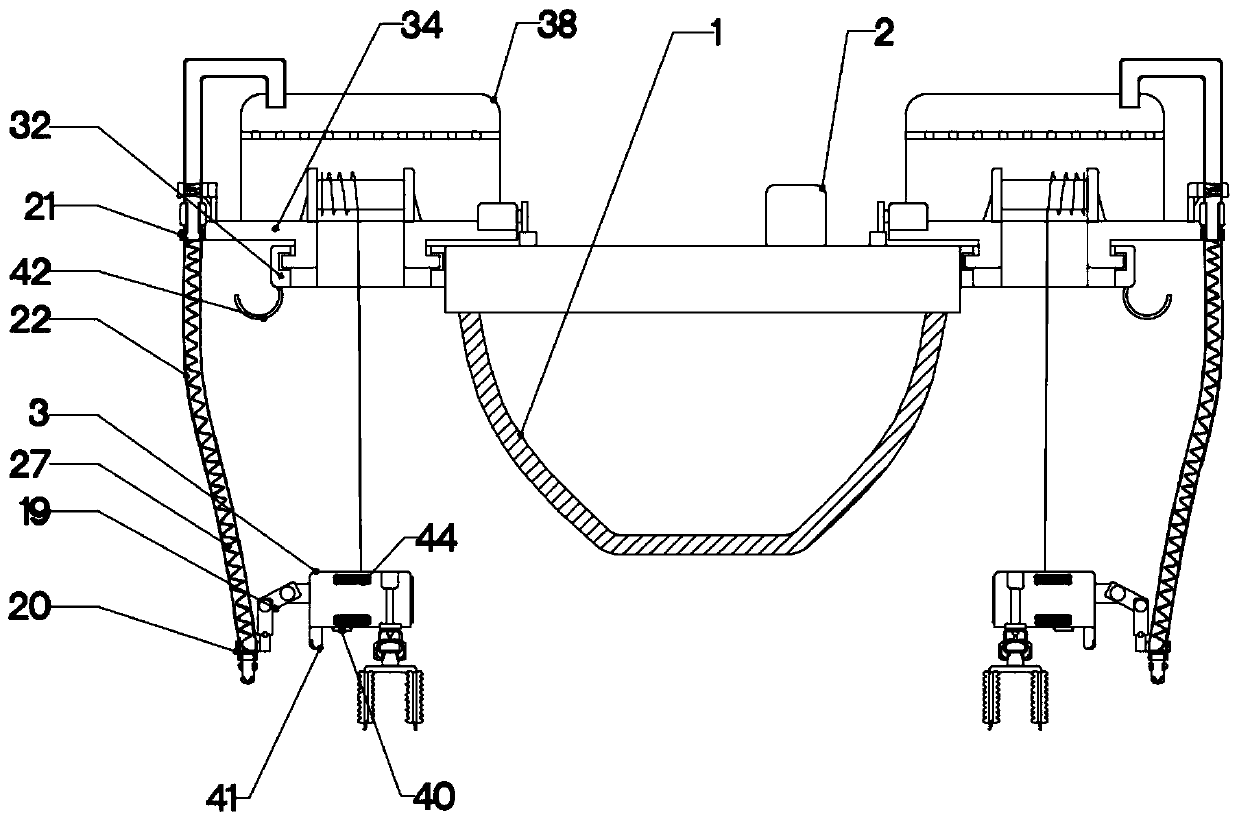

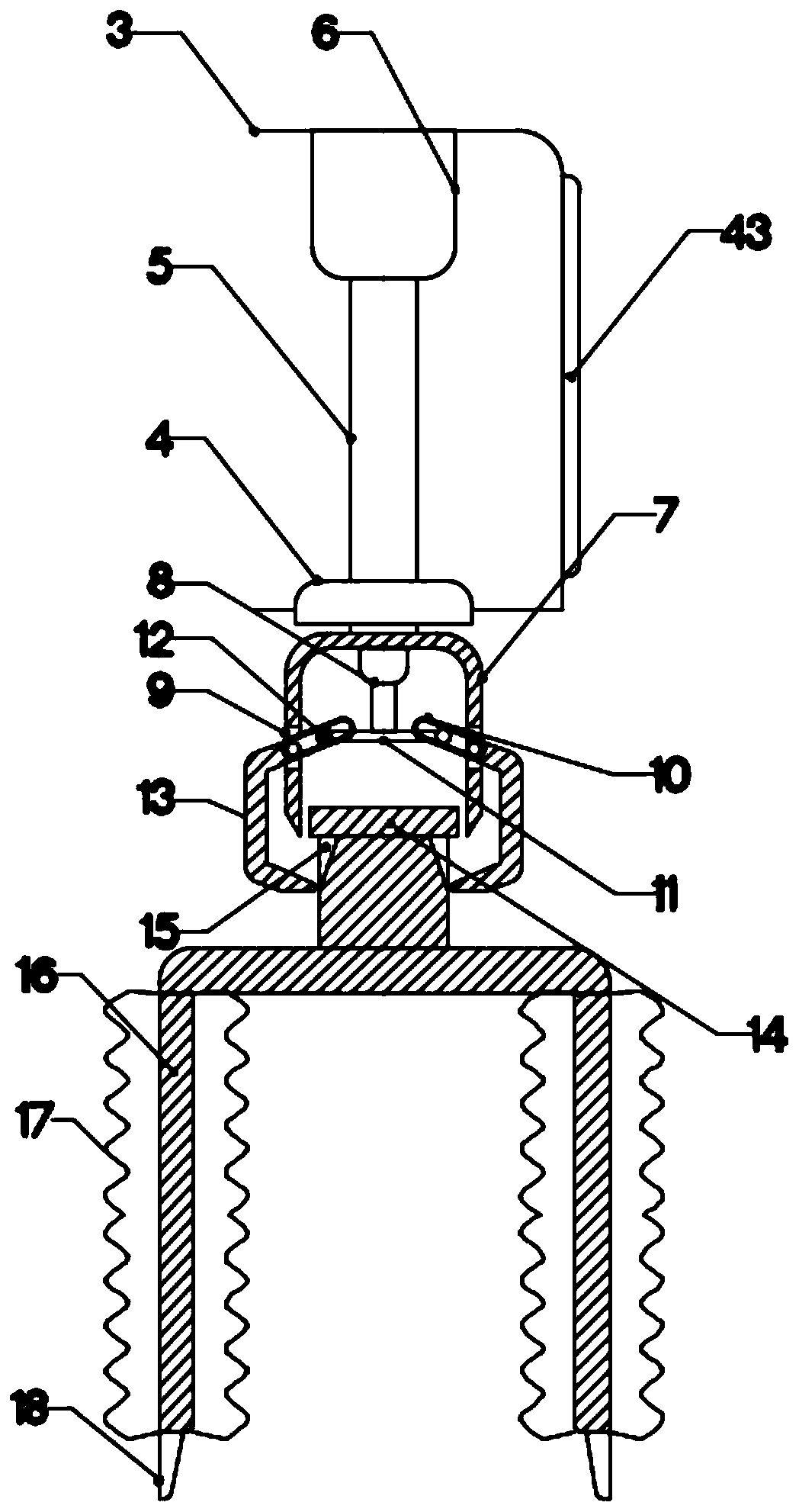

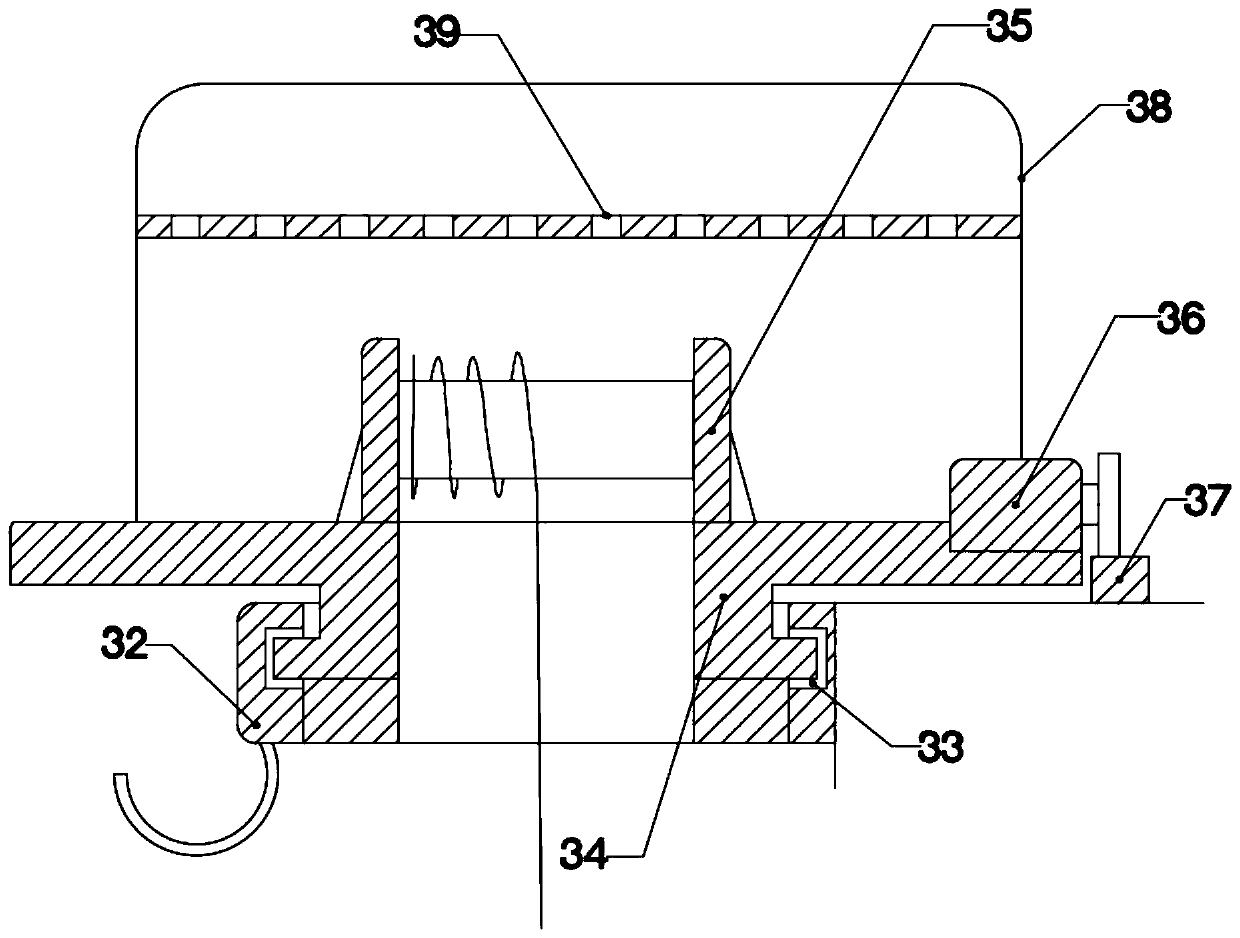

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0025] In this embodiment, the model of the controller 2 is MSP430, and the control signal output terminal of the controller 2 is connected to the rotary motor 6, the waterproof linear motor 8, the mechanical arm 19, the hollow shaft motor 23, the suction pump 31, the winch 35, the distance The control signal input ends of the sensor 40 and the camera 41 are electrically connected, and the power output end of the controller 2 is connected to the rotating motor 6, the waterproof linear motor 8, the mechanical arm 19, the hollow shaft motor 23, the suction pump 31, the winch 35, and the distance The power input terminals of the sensor 40 and the camera 41 are electrically connected. The signal output end of the camera 41 is electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com