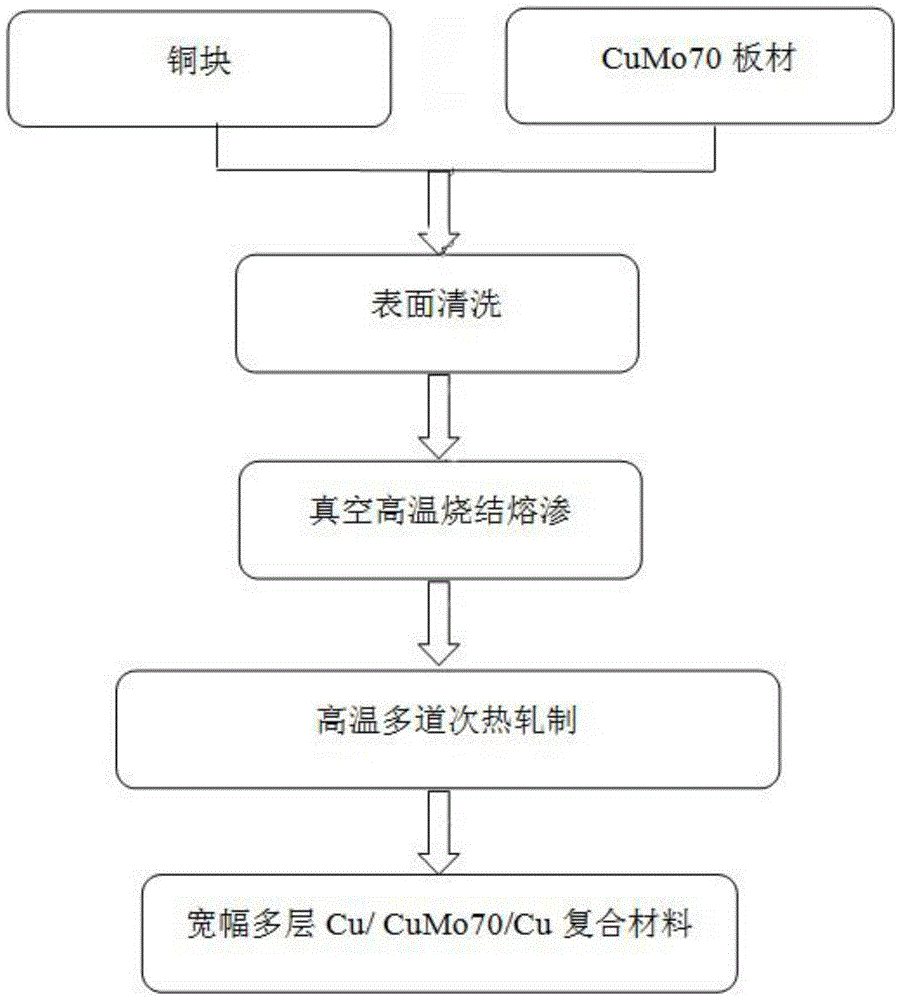

Preparation method of wide multi-layer cu-cumo70-cu composite material

A cu-cumo70-cu and composite material technology is applied in the field of preparation of wide-width multi-layer Cu-CuMo70-Cu composite materials, which can solve cracking, cannot prepare wide-width and large-size multi-layer Cu-Mo-Cu composite materials, deformation and other problems, to achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In order to prepare a 3-layer Cu-CuMo70-Cu composite material, a mold with 3 layers of heterogeneous materials was designed, a CuMo70 plate with a size of 100mm×100mm×3mm was machined, and a T2 pure Cu material with a size of Φ48mm×198mm was prepared ;

[0030] Wash the residual scale on the surface of the Cu material with gasoline, and then use alcohol to clean the oil stains remaining on the surface of the Cu material; perform electrolytic corrosion of 75% phosphoric acid on the surface of the CuMo70 plate for 1 min;

[0031] Put the CuMo70 plate in the middle layer of the 3-layer heterogeneous material forming mold, put the surface-treated Cu material into the graphite crucible, and add 10 grams of CuNi10 material to it, place the graphite crucible on the mold and put it into the ZRS- In the 18Q microcomputer program-controlled vacuum high-temperature sintering furnace, vacuum the ZRS-18Q microcomputer program-controlled vacuum high-temperature sintering furnace. Whe...

Embodiment 2

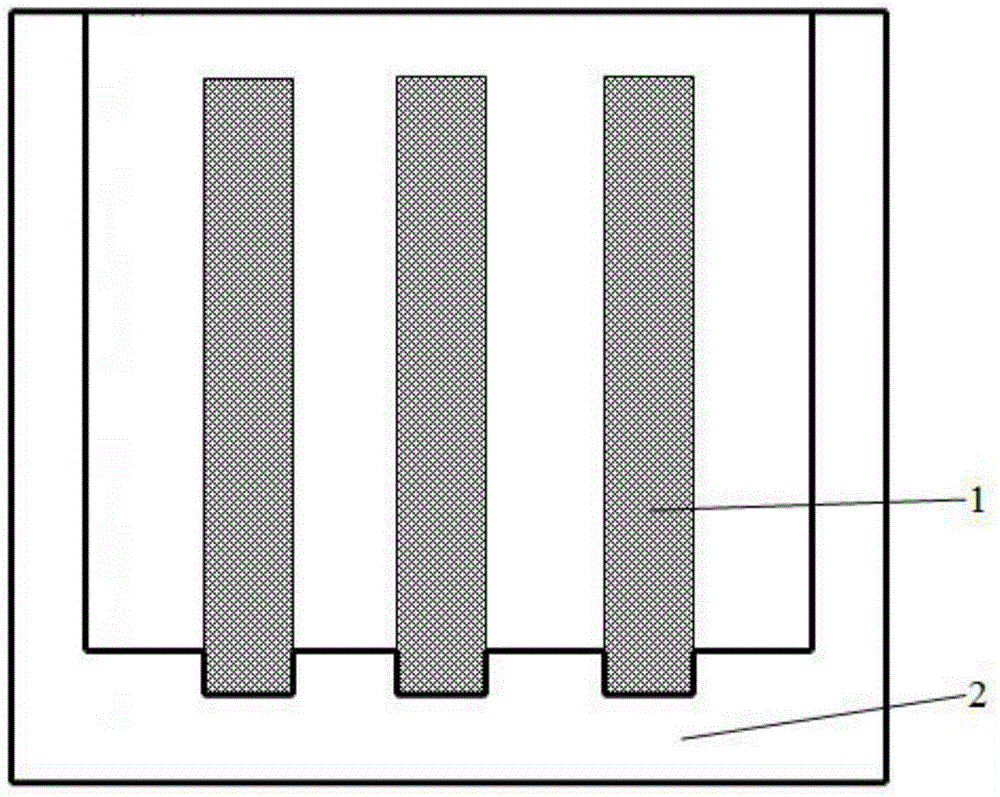

[0034] In order to prepare 7-layer Cu-CuMo70-Cu composites, the design as figure 2 The mold 2 shown has 7 layers of heterogeneous material molding, machining 3 CuMo70 plates with a size of 100mm×100mm×1mm, and preparing a T2 pure Cu material with a size of Φ48mm×172mm;

[0035] Wash the residual scale on the surface of the Cu material with gasoline, and then use alcohol to clean the oil stains remaining on the surface of the Cu material; perform electrolytic corrosion of 75% phosphoric acid on the surface of the CuMo70 plate for 2 minutes;

[0036]Put the pretreated CuMo70 plate 1 on the even-numbered layer in the 7-layer heterogeneous material forming mold 2, put the Cu material for surface treatment into the graphite crucible, and add 30 grams of CuNi10 material therein, and place the graphite crucible on the mold Put it into the ZRS-18Q microcomputer program-controlled vacuum high-temperature sintering furnace, and vacuum the ZRS-18Q microcomputer program-controlled vacuum...

Embodiment 3

[0039] In order to prepare a 13-layer Cu-CuMo70-Cu composite material, a mold with 13 layers of heterogeneous materials was designed, 6 CuMo70 plates with a size of 100mm×100mm×0.8mm were machined, and T2 pure Cu with a size of Φ48mm×132mm was prepared Material;

[0040] Rinse the residual scale on the surface of the Cu material with gasoline, and then use alcohol to clean the oil stains remaining on the surface of the Cu material; perform electrolytic corrosion of 75% phosphoric acid on the surface of the CuMo70 plate for 3 minutes;

[0041] Put the pre-treated CuMo70 sheet on the even-numbered layer in the 13-layer heterogeneous material forming mold, put the surface-treated Cu material into the graphite crucible, and add 60 grams of CuNi10 material into it, put the graphite crucible on the mold and put it into ZRS -18Q microcomputer program-controlled vacuum high-temperature sintering furnace, vacuumize the ZRS-18Q microcomputer program-controlled vacuum high-temperature si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com