Special-shaped square cabin

A special-shaped shelter technology, applied in armored vehicles, motor vehicles, transportation and packaging, etc., can solve the problem of poor electromagnetic shielding, special-shaped shelters that cannot meet thermal insulation, electromagnetic shielding and stealth, and the cabin does not have stealth and other issues, to achieve good thermal insulation and air tightness, the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

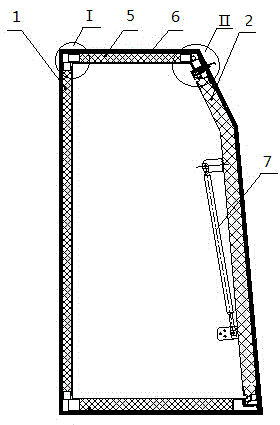

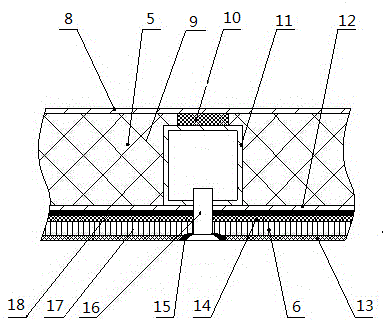

[0030] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

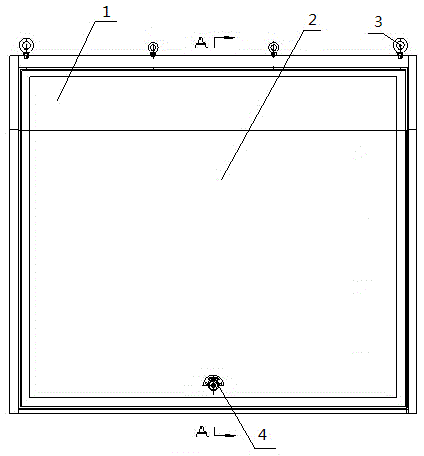

[0031] As shown in the drawings: a special-shaped shelter, including a shelter body 1 composed of upper, lower, left, right, front and rear wall panels 5, the shelter body 1 is provided with a hatch 2, and the wall panels 5 include inner Mongolia Board 8, metal skeleton 11, outer covering board 12, metal skeleton 11 is scattered between inner covering board 8 and outer covering board 12, and is connected with outer covering board 12, and a heat insulating layer is provided between metal skeleton 11 and inner covering board 8 10. The heat insulation material used in the heat insulation layer 10 is a vacuum heat insulation board, which has a good heat insulation effect. There is also a polyethylene foam 9 between the inner cover board 8 and the outer cover board 12. The thickness of the polyethylene foam 9 is 30 Between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com