Plasma recombination boosting turbine fan jet aerial engine

An aero-engine and turbofan technology, applied in the field of aero-engines, can solve serious problems affecting combat maneuverability, air pollution, etc., and achieve the effects of reducing environmental pollutants, saving aviation kerosene, and quickly capturing targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

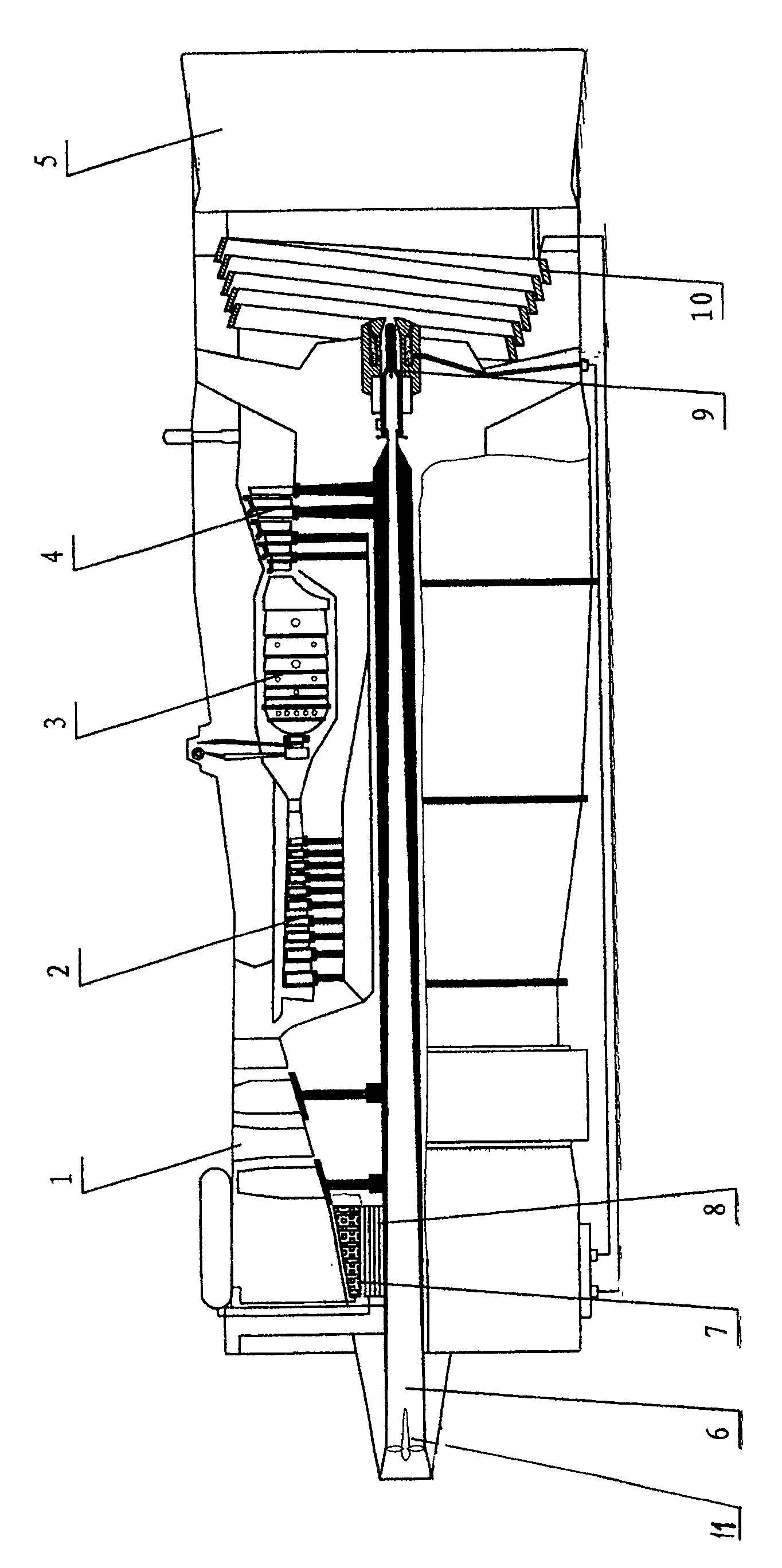

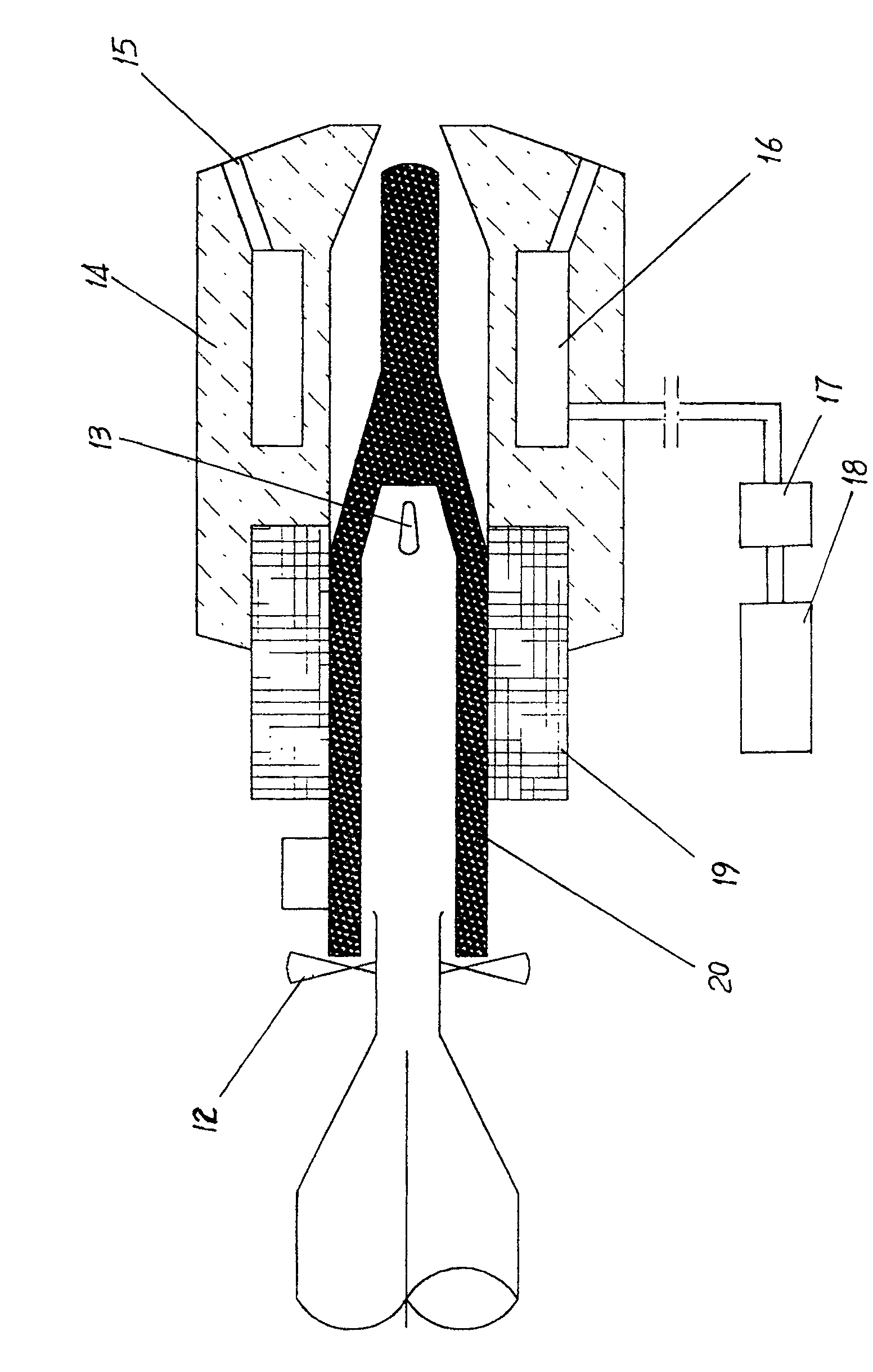

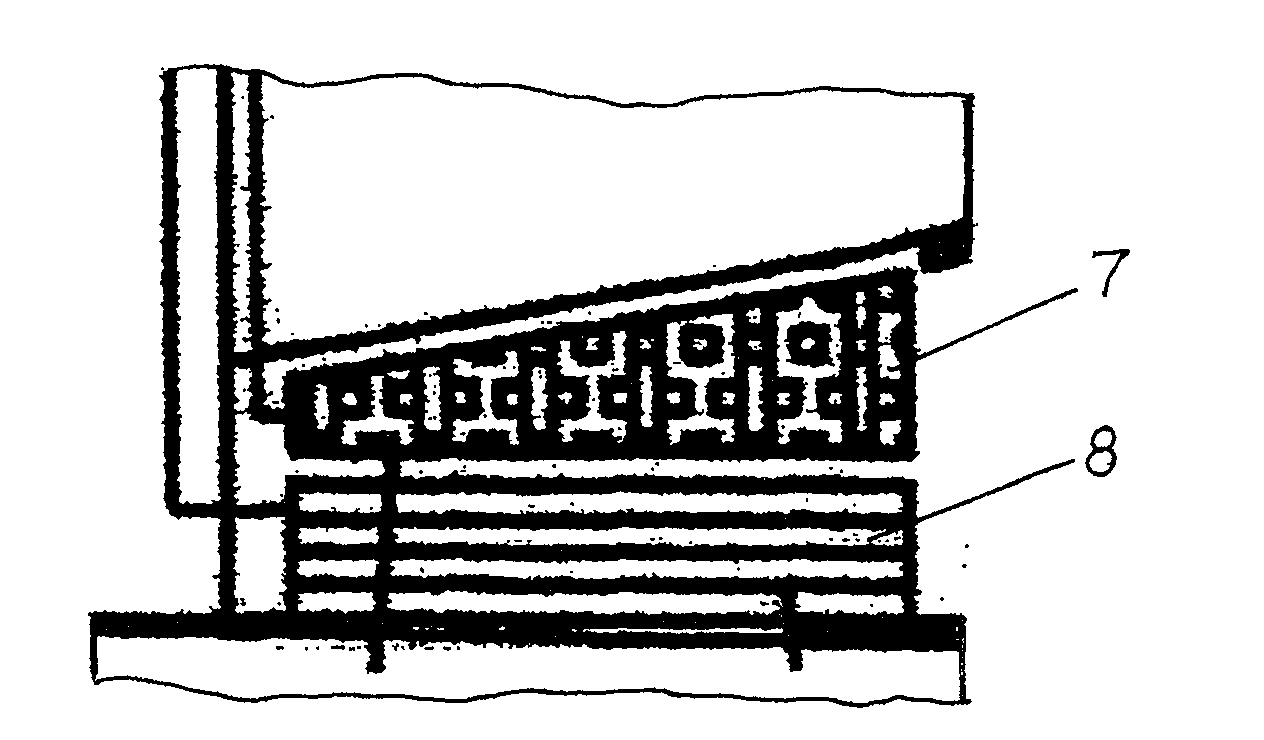

[0016] See figure 1 -5, the concrete structure of the present invention is as follows: it adopts the structure of the low-pressure fan 1, the high-pressure compressor 2, the combustion chamber 3, the turbine 4, and the tail nozzle 5 of the existing turbojet engine. The shaft 6 is provided with an inner cone axis duct, and an impeller 11 composed of twisted blades is fixed at the entrance of the front end of the shaft duct. The body is compressed to 4.2 atmospheres, and a dynamic sealing impeller 12 is installed outside the shaft tail of the turbine shaft 6 to ensure that the compressed air does not leak out, and an air hole 13 is opened at the shaft tail to deliver the air pressure to the plasma generator 9. Assemble the nano permanent magnetic steel rotor 8 on the turbine shaft 6, select the superconducting material N b12 AL 2 Ge, three times higher current density than copper conductor material. A superconducting material stator 7 is assembled on the periphery of the nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com