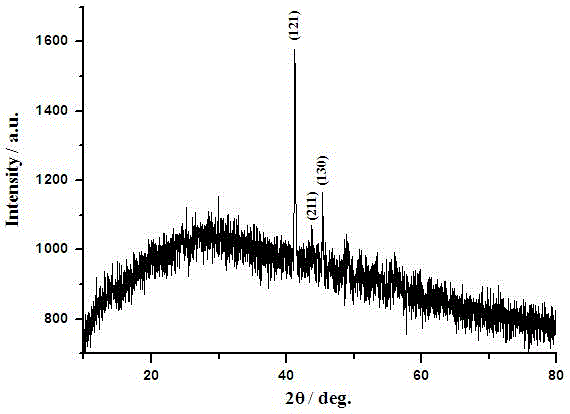

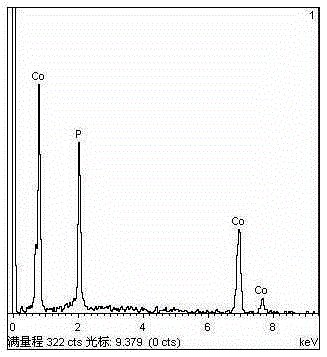

A kind of preparation method of transition metal phosphide co2p

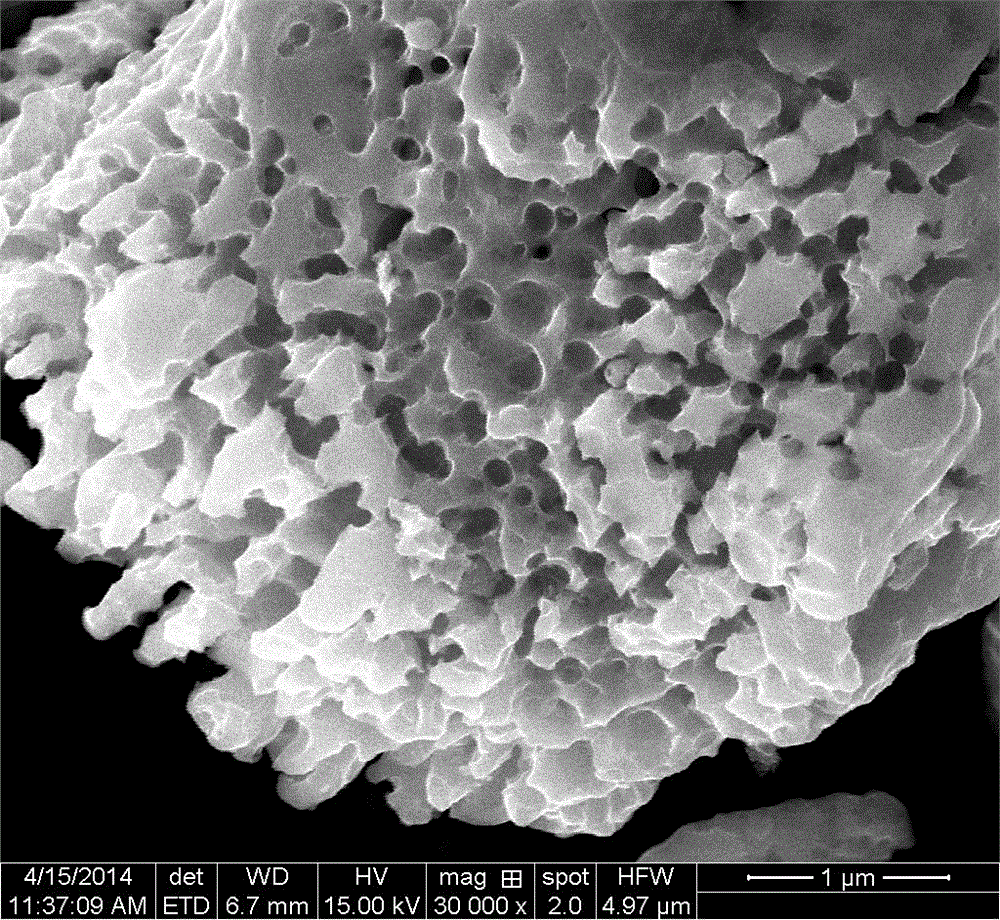

A transition metal and phosphide technology, applied in phosphide and other directions, can solve the problems of unsuitable control and complicated procedures, and achieve the effect of reducing preparation requirements, simple process and more pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) The raw materials are weighed according to the mass percentage of industrial pure copper 19.90%, copper-cobalt alloy 51.50%, copper-phosphorus alloy 28.60%. Wherein the mass percentage of copper in the copper-cobalt alloy is 70.3%, and the mass percentage of cobalt is 29.7%; The mass percentage of copper in the copper-phosphorus alloy is 86.0%, and the mass percentage of phosphorus is 14.0%;

[0030] (2) In a vacuum arc melting furnace, copper-cobalt-phosphorus alloy ingots are melted. The specific steps are as follows: put the prepared raw materials in the copper crucible of the electric arc furnace, adjust to the intermediate frequency, use arc discharge to generate high temperature, control the heating time to 60s, and melt to obtain the mother ingot. Here, the smelting was repeated 5 times to ensure uniform smelting. The surface oxide layer of the alloy master ingot must be removed after each smelting

[0031] (3) The obtained copper-cobalt-phosphorus alloy ma...

Embodiment 2

[0034] (1) The raw materials are weighed according to the mass percentage of industrial pure copper 13.85%, copper-cobalt alloy 50.00%, copper-phosphorus alloy 36.15%. The mass percentage of copper in the copper-cobalt alloy is 80.0%, and the mass percentage of cobalt is 20.0%; the mass percentage of copper in the copper-phosphorus alloy is 91.7%, and the mass percentage of phosphorus is 8.3%.

[0035] (2) In a vacuum arc melting furnace, copper-cobalt-phosphorus alloy ingots are melted. The specific steps are as follows: put the prepared raw materials in the copper crucible of the electric arc furnace, adjust to the intermediate frequency, use arc discharge to generate high temperature, control the heating time to 50s, and melt to obtain the mother ingot. Here, the smelting was repeated 4 times to ensure uniform smelting. After each smelting, the surface oxide layer of the alloy master ingot should be removed.

[0036] (3) The obtained copper-cobalt-phosphorus alloy master ...

Embodiment 3

[0039] (1) The raw materials are weighed according to the mass percentage of industrial pure copper 14.30%, copper-cobalt alloy 28.60%, copper-phosphorus alloy 57.10%. The mass percentage of copper in the copper-cobalt alloy is 93.0%, and the mass percentage of cobalt is 7.0%; the mass percentage of copper in the copper-phosphorus alloy is 93.0%, and the mass percentage of phosphorus is 7.0%.

[0040] (2) In a vacuum arc melting furnace, copper-cobalt-phosphorus alloy ingots are melted. The specific steps are as follows: put the prepared raw materials in the copper crucible of the electric arc furnace, adjust to the intermediate frequency, use arc discharge to generate high temperature, control the heating time to 45s, and melt to obtain the mother ingot. Here, the smelting was repeated 3 times to ensure uniform smelting. After each smelting, the surface oxide layer of the alloy master ingot should be removed.

[0041] (3) The obtained copper-cobalt-phosphorus alloy is subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com