Tantalum-doped cubic garnet structure Li7La3Zr2-xTaxO12 material and preparation method thereof

A garnet and cubic technology, which is applied in the field of lithium-ion battery electrolyte materials, can solve problems such as cost increase, energy consumption, and Li element loss, and achieve the effects of energy saving, good crystal form, and reduced content requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

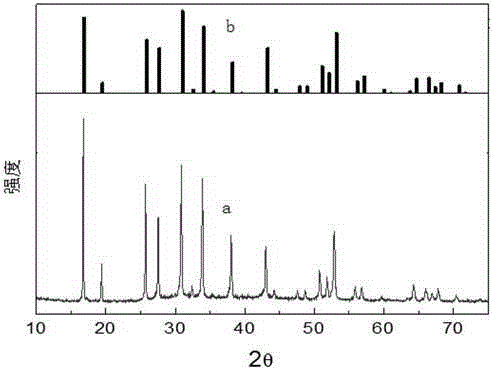

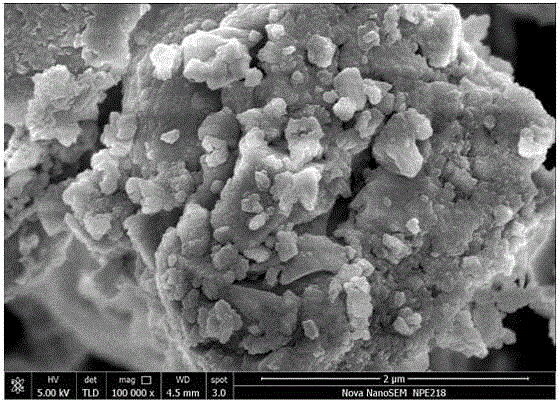

Image

Examples

Embodiment 1

[0026] (1) Weigh lanthanum zirconate, lanthanum oxide, lithium acetate and lithium tantalate. The molar ratio of lanthanum zirconate to lanthanum oxide is 7:5, the molar ratio of lanthanum zirconate to lithium acetate is 1:8, and the molar ratio of lanthanum zirconate to lithium acetate is 1:8. The molar ratio to lithium tantalate is 7:2 to comply with Li 7 La 3 Zr 1.75 Ta 0.25 O 12 The molar ratio of the elements in the molecular formula. The above materials were successively placed in a glass beaker and a complexing agent was added and stirred for 6 hours.

[0027] (2) After the mixing is uniform, the stirrer starts to heat, and the temperature is gradually raised to 80 °C and kept at a temperature until the excess water is removed, and the final paste is the precursor of the high-temperature solid-phase treatment.

[0028] (3) Pre-heat the precursor at 400°C for 3 hours in a tube furnace to remove cyclodextrin and a small amount of residual water, and take out the prod...

Embodiment 2

[0033] (1) Weigh lanthanum zirconate, lanthanum oxide, lithium acetate and lithium tantalate. The molar ratio of lanthanum zirconate to lanthanum hydroxide is 7:10, the molar ratio of lanthanum zirconate to lithium acetate is 1:8, and the zirconate The molar ratio of lanthanum to lithium tantalate was 7:2 to match the Li 7 La 3 Zr 1.75 Ta 0.25 O 12 molar ratio. The above materials were successively placed in a glass beaker and a complexing agent was added and stirred for 4 hours.

[0034] (2) After the mixing is uniform, the stirrer starts to heat, and the temperature is gradually raised to 80 °C and kept at a temperature until the excess water is removed, and the final paste is the precursor of the high-temperature solid-phase treatment.

[0035] (3) Pre-heat the precursor at 400°C for 3 hours in a tube furnace to remove cyclodextrin and a small amount of residual water, and take out the product, fully grind it with an agate mortar, and then roast it in a tube furnace at...

Embodiment 3

[0038] (1) Weigh lanthanum zirconate, lanthanum oxide, lithium nitrate and lithium tantalate. The molar ratio of lanthanum zirconate to lanthanum oxide is 7:5, the molar ratio of lanthanum zirconate to lithium nitrate is 1:8, and the molar ratio of lanthanum zirconate to lithium nitrate is 1:8. The molar ratio to lithium tantalate is 7:2 to comply with Li 7 La 3 Zr 1.75 Ta 0.25 O 12 molar ratio. The above materials were successively placed in a glass beaker and a complexing agent was added and stirred for 4 hours.

[0039] (2) After the mixing is uniform, the stirrer starts to heat, and the temperature is gradually raised to 80 °C and kept at a temperature until the excess water is removed, and the final paste is the precursor of the high-temperature solid-phase treatment.

[0040] (3) Pre-heat the precursor at 400°C for 4 hours in a tube furnace to remove cyclodextrin and a small amount of residual water, and take out the product, fully grind it with an agate mortar, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com