Preparation method of neohesperidin without heavy metals

A new hesperidin and heavy metal removal technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., to achieve the effects of ensuring balance, reducing the effect of impurity removal, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0087] Preparation of modified chitosan: the modification method is the chloroacetic acid method. Specifically, after soaking and swelling 10g chitosan in 10L deionized water, add 50ml, 36% hydrochloric acid to fully dissolve it, and then add 10g sodium hydroxide and 40g of chloroacetic acid at a temperature of 40°C for 1 hour to carboxymethylate chitosan, and finally obtain it after separation and purification by ethanol precipitation.

Embodiment 1

[0089] 1. Impurity removal: After 50kg of citrus aurantium is broken, add 500kg in three times, pH is 4.5 (hydrochloric acid), basic zinc chloride concentration is 0.9%, ethanol volume fraction is the aqueous solution of 5% 4 ℃, each time Leakage and reflux for 4 hours, after bag centrifugation, collect and remove impurities;

[0090] 2. Extraction: Add 500kg of hot water at 90°C to the obtained residue for three times, stirring and extracting for 3 hours each time, centrifuging with cloth bag while it is hot, and collecting 363.2kg of extracting filtrate;

[0091] 3. Flocculation: Dissolve 2.5kg of the modified chitosan prepared in Preparation Example 1 in 10L of 1% acetic acid solution, then pour it all into the filtrate. A ceramic membrane with a molecular weight cut-off of 4000Da obtained a permeate of 335.6kg with a sugar content of 2.3brix;

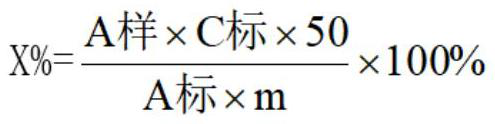

[0092] 4. Chromatography: Put the permeate on the cation exchange chromatography column, the resin type is D113, the column volum...

Embodiment 2

[0099] Other operations and conditions are the same as in Example 1, except that in step 1, the basic salt is basic aluminum sulfate with a concentration of 1.5 wt%. Finally, the product neohesperidin is obtained. Through detection and calculation, it is obtained that the purity of the neohesperidin product is 99.3%, and the total yield is 92.1%; heavy metals in the product are not detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com