Plate cavity-type heat exchanger

A technology of heat exchanger and plate cavity, which is applied in the field of plate cavity phase change heat exchange device, can solve the problem of difficult to meet higher pressure requirements, limit the flow of heat carrier in the flow space of working medium fluid chamber, and the thermal conductivity is not very high, etc. problem, to achieve the effect of improving heat exchange efficiency, improving pressure bearing performance, and optimizing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

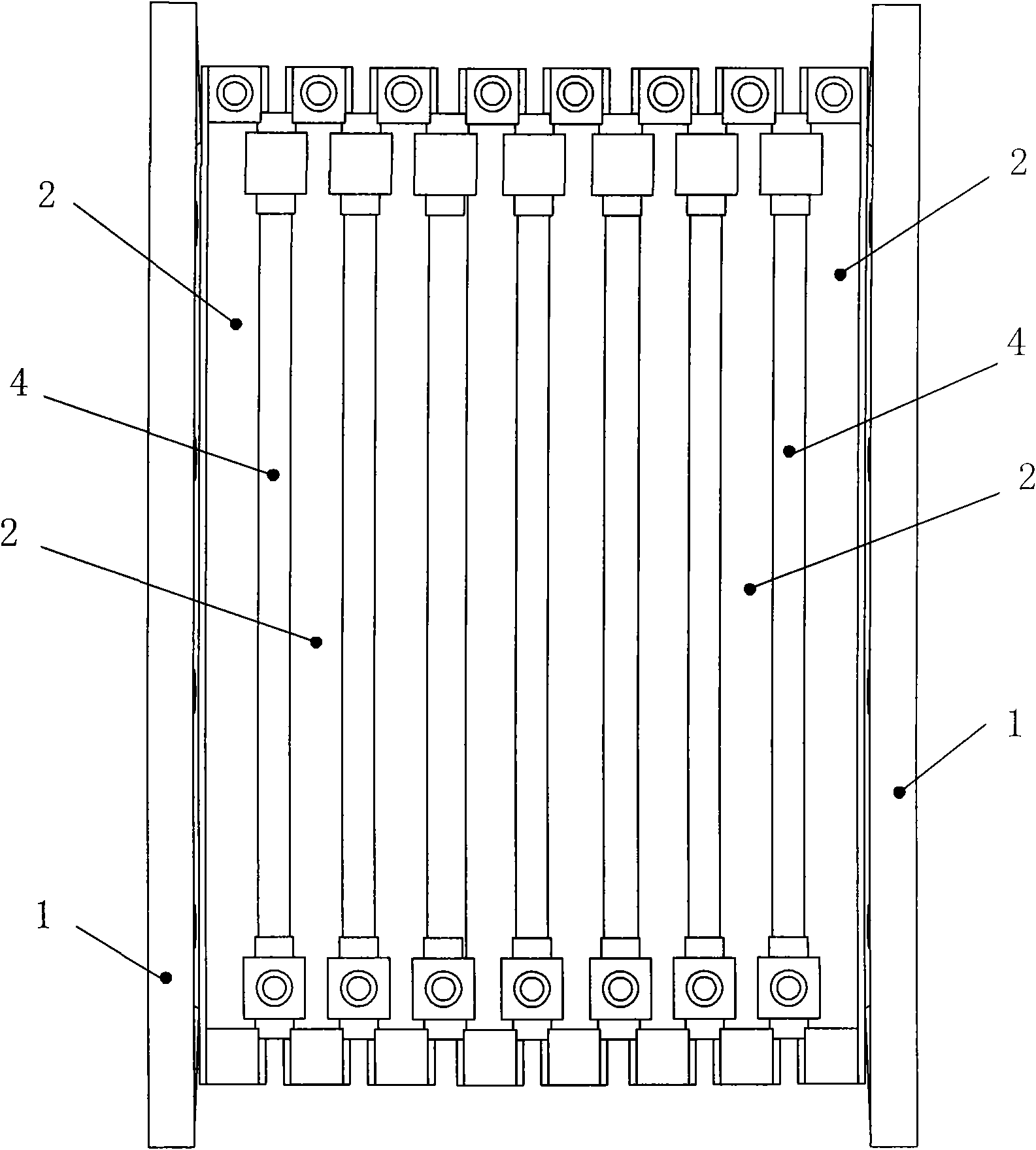

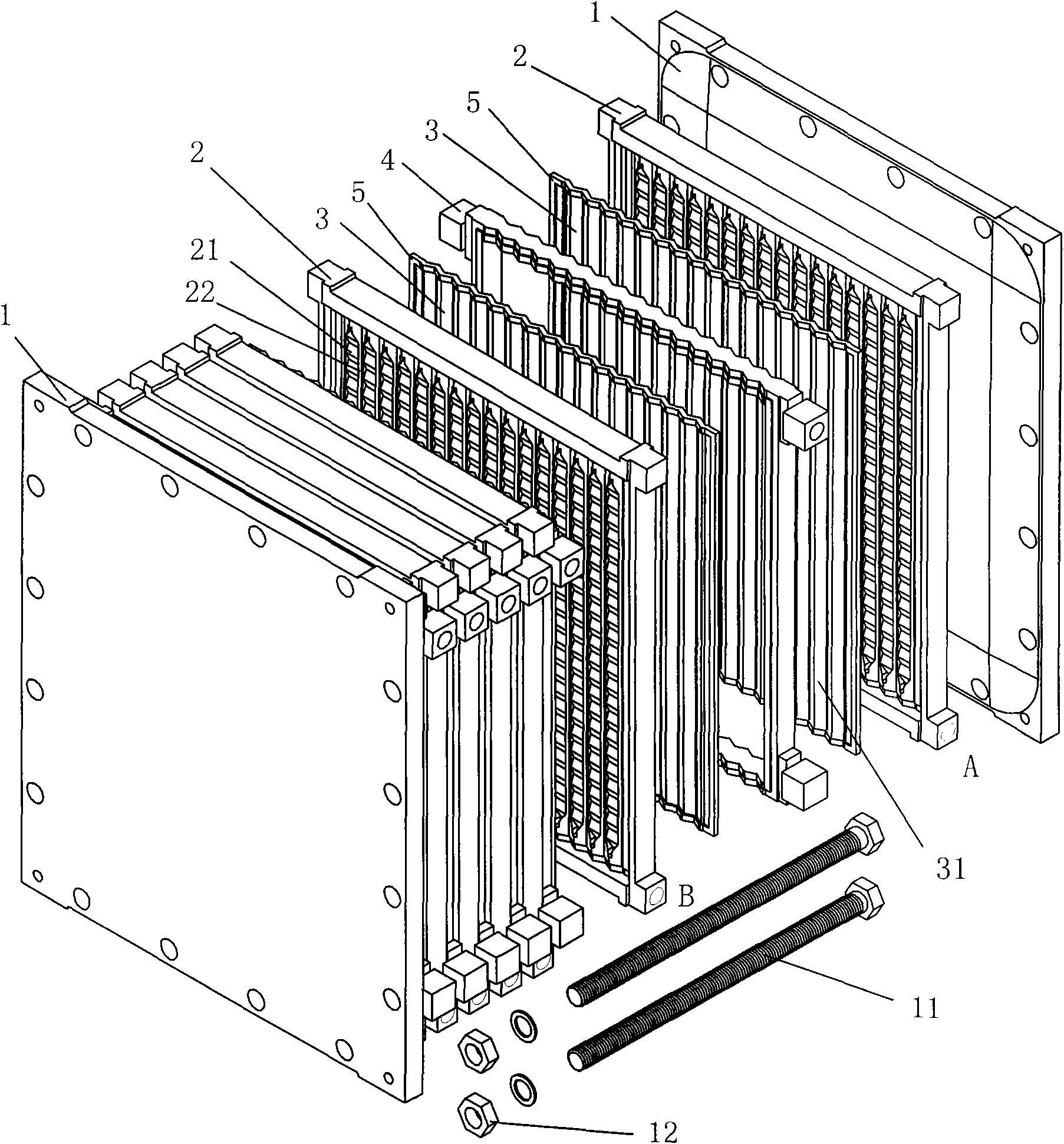

[0025] see figure 1 , figure 2 , In this example, there are 6 heat exchange units sandwiched between a pair of compression plates 1 . Each heat exchange unit includes a cavity frame 4, two heat exchange wave plates 3, and two water plates 2, and adjacent heat exchange units can share one water plate. The two pressing plates 1 are connected by fastening bolts 11 and fastening nuts 12, so as to press and connect the components of each heat exchange unit as a whole.

[0026] see figure 2 , is a schematic diagram of the split state structure of a heat exchange unit adjacent to the compression plate 1:

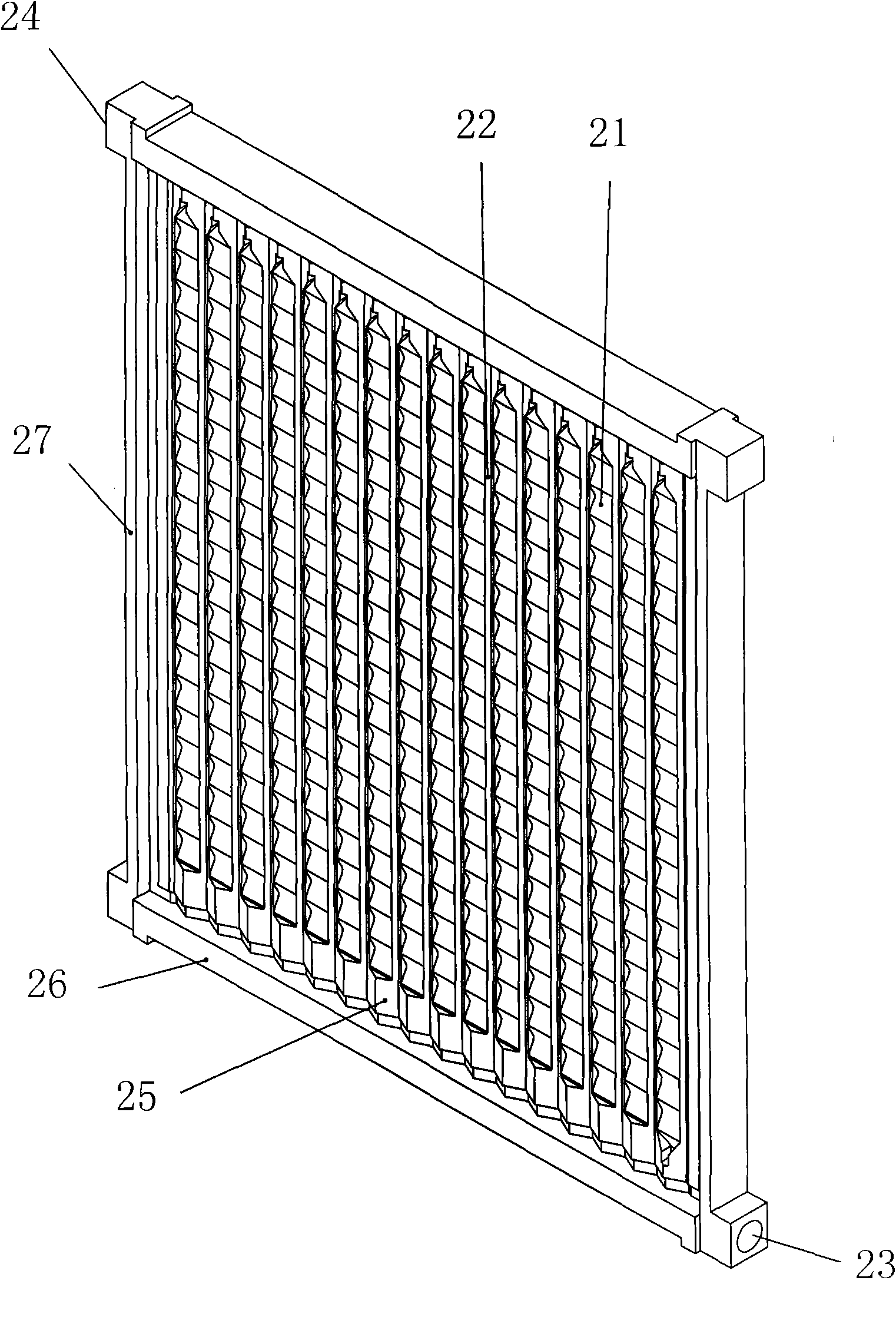

[0027] The cross-sections of the two corrugated plates 3 opposite to each other are triangular waveforms, the two sides of the corrugated plates present longitudinal corrugated grooves arranged side by side, and the directions of the corrugated corrugated grooves 31 on the two corrugated plates are consistent;

[0028] The cross-section of the wave plate can also be sinusoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com