Lead lanthanum zirconate stannate antiferroelectric ceramic as well as preparation method and application thereof

A technology of lanthanum zirconate stannate and antiferroelectricity, which is applied in the field of lanthanum zirconate stannate lead antiferroelectric ceramics and its preparation, can solve the problems of low transition electric field and polarization strength, low energy storage efficiency, etc., and achieve simple preparation method , Improve the effect of density and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

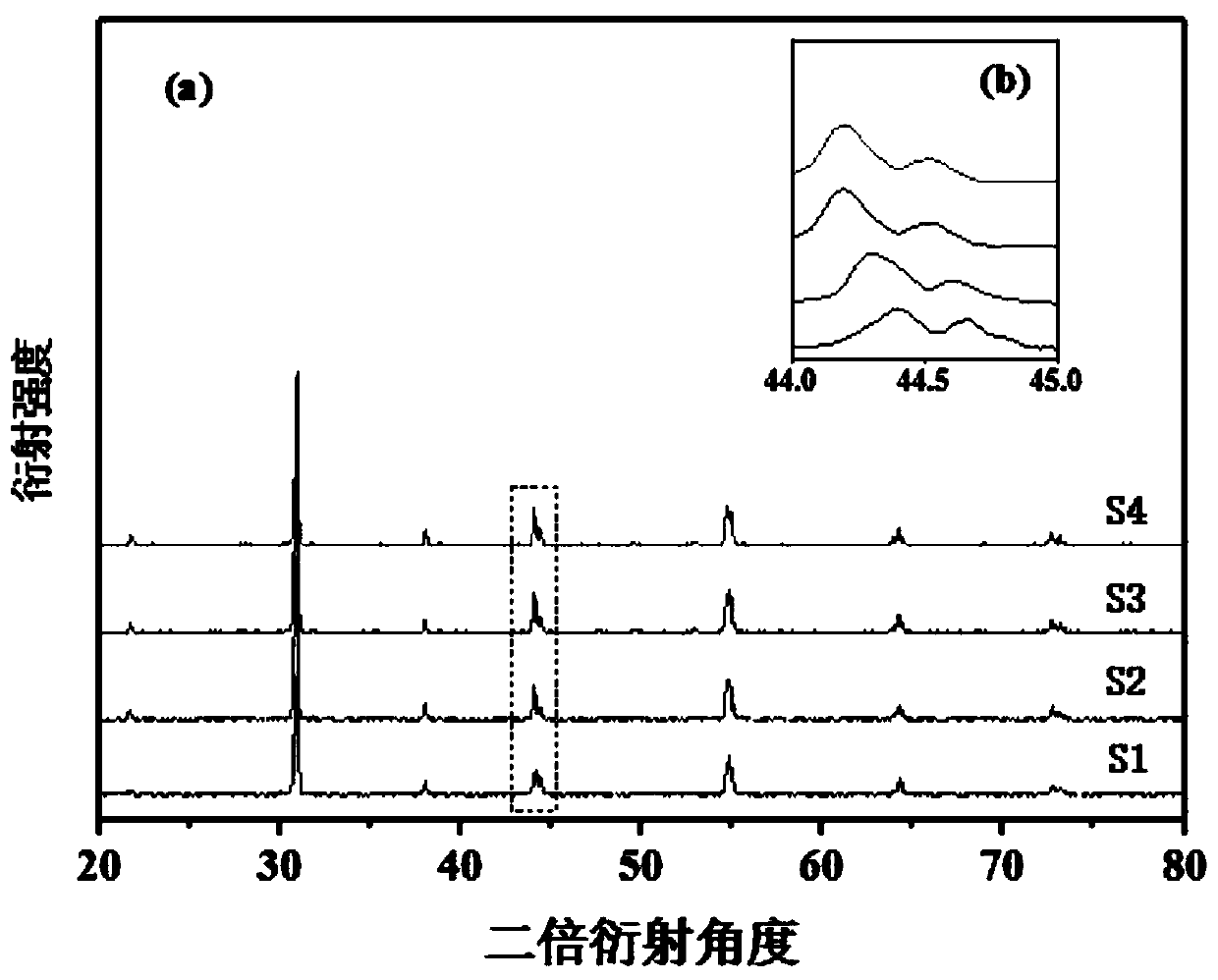

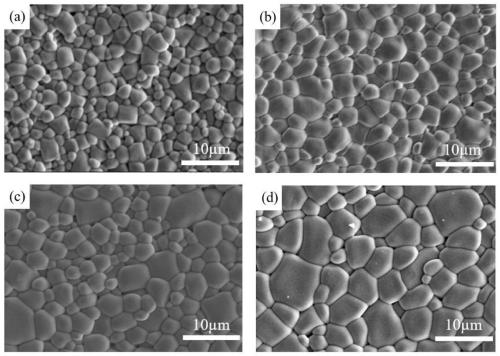

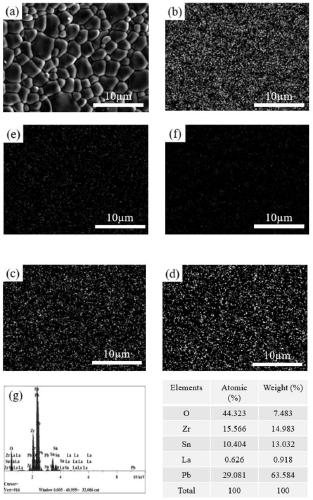

Embodiment 1

[0035] 1. According to the stoichiometric ratio of PbO (excess 5wt% PbO), La 2 o 3 , ZrO 2 , SnO 2 Put it in a nylon ball mill jar (250mL), the ball milling medium is zirconia balls (ball diameters are 3mm and 5mm, the mass ratio is about 1:1); use an ordinary planetary ball mill for ball milling, add ethanol, set the speed at 250rmp, and the ball milling time is 24h .

[0036] 2. Put the ball-milled powder in an oven, dry at 60°C for 10 hours, and pass through 40-mesh and 80-mesh sieves respectively to obtain ceramic powder;

[0037] 3. Put the ceramic powder in a muffle furnace for pre-calcination at 900°C for 2 hours, then use an ordinary planetary ball mill to mill, add ethanol, set the speed at 250rmp, and mill for 24 hours for the second ball mill, and place the milled powder in an oven , dried at 60°C for 10 hours, and passed through 40-mesh and 80-mesh sieves respectively to obtain ceramic powder;

[0038]4. Add the obtained ceramic powder to the binder PVB at a m...

Embodiment 2

[0041] Different from Example 1 in that: Pb is produced 0.97 La0.02(Zr x sn 1-x )O 3 (PLZS) Ceramics. where x=0.50 (marked as S2).

Embodiment 3

[0043] Different from Example 1 in that: Pb is produced 0.97 La0.02(Zr x sn 1-x )O 3 (PLZS) Ceramics. where x=0.55 (marked as S3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com