Dust absorbing, dust removing inner wall decorative coating and preparation thereof

A technology for decorative coatings and interior walls, applied in the field of building materials, can solve problems such as failure to control high-concentration dust in the living room, control of dust particles that have not received due attention, and human health hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Ingredients Mass (g)

[0035] water 200

[0036] Cellulose 2.5

[0037] pH regulator AMP-95 1

[0038] Propylene Glycol 5

[0039] Dispersant DP-270 2

[0040] Defoamer NXZ 8

[0041] Nano-TiO 2 30

[0042] Kaolin 100

[0043] heavy calcium 150

[0044] Talc 35

[0045] Tourmaline 70

[0046] Vinegar Acrylic Emulsion 70

[0047] Alcohol ester dodeca 2.5

[0048] Antifungal agent HF 3

[0049] Prepare the coating according to the above-mentioned ingredients and method. Using the paint (200g / m 2 ) coatings, respectively, for functional testing:

[0050] Test Methods:

[0051] 1. Number of dust particles: Place the prepared fiber sample in a closed glass chamber. From the opening on the top of the bin, evenly spray powder and dust. Then use the five-point method to observe the number of dust particles in the sample per unit area under a high-power microscope.

[0052]The experimental results show that the number of dust particles per unit area o...

Embodiment 2

[0055] Embodiment two: make coating by following batching.

[0056] Ingredients Mass (g)

[0057] water 200

[0058] Thickener TT935 1.5

[0059] pH regulator AMP-95 1

[0060] Ethylene glycol 2

[0061] Dispersant B03 5

[0062] Defoamer 8034 6

[0063] Nano-TiO 2 120

[0064] Kaolin 150

[0065] heavy calcium 35

[0066] Light Calcium 100

[0068] Tourmaline 80

[0069] Lanthanum lead zirconate titanate 3

[0070] Vinegar Acrylic Emulsion 80

[0071] Alcohol ester dodeca 2

[0072] Antifungal agent HF 1.5

[0073] Carry out functional test with the method identical with embodiment one, result: the number of dust particles per unit area of this example dust-absorbing, dust-reducing coating is 35 times of common coating; The contact angle is 35 °; High-quality wall paint requirements.

Embodiment 3

[0074] Embodiment three: make coating by following batching.

[0075] Ingredients Mass (g)

[0076] water 200

[0077] Thickener RM-8W 1.5

[0078] pH regulator AMP-95 1

[0079] Dispersant DP-270 2

[0080] Defoamer 4481 5

[0081] Nano-TiO 2 20

[0082] Kaolin 120

[0083] heavy calcium 120

[0084] lithopone 50

[0085] Tourmaline 28

[0086] Styrene acrylic emulsion 80

[0087] Alcohol esters twelve 3

[0088] Antifungal agent N-96 5

[0089] Carry out functional test with the method identical with embodiment one, result: the number of dust particles per unit area of this example dust-absorbing, dust-reducing coating is 10 times of common coating; Contact angle is 40 °; High-quality wall paint requirements.

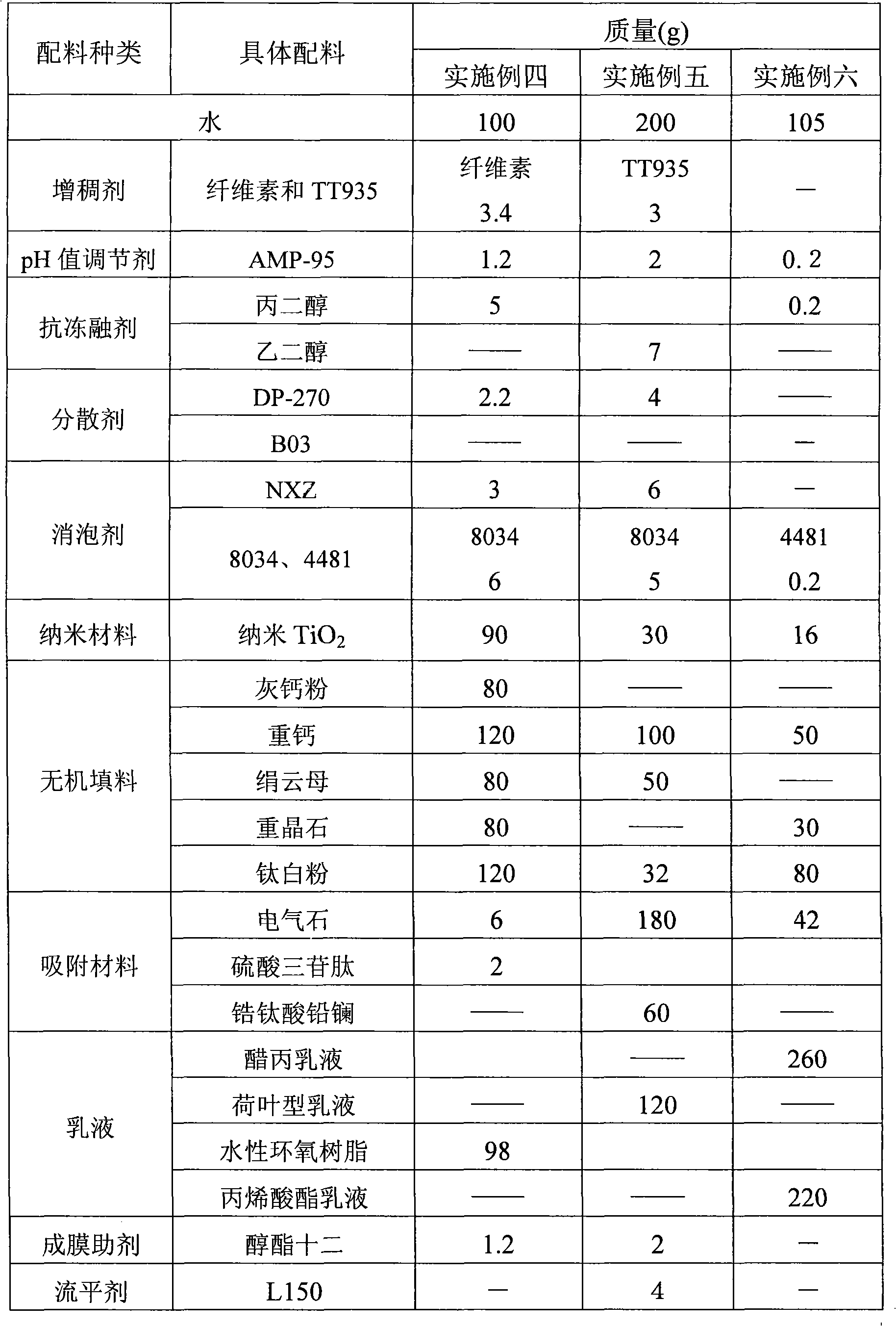

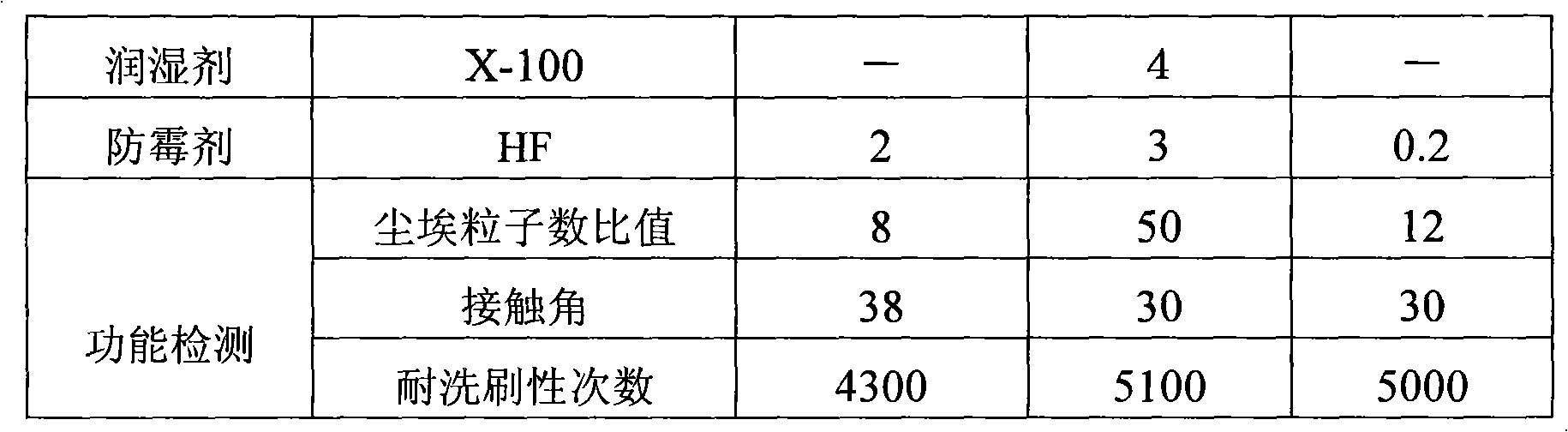

[0090] Embodiment four to six: make coating according to following table batching.

[0091]

[0092]

[0093] The above experiments show that the dust-absorbing and dust-reducing ability of the coating of the present invention is more t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com