Printing-free frosted hardened film for in-mold decoration

An in-mold decoration, printing-free technology, applied in special decorative structures, decorative arts, polyurea/polyurethane coatings, etc., can solve the problems of unenvironmental protection, time-consuming and labor-intensive, etc., to improve production efficiency, environmental friendliness, solve moldability and The effect of surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

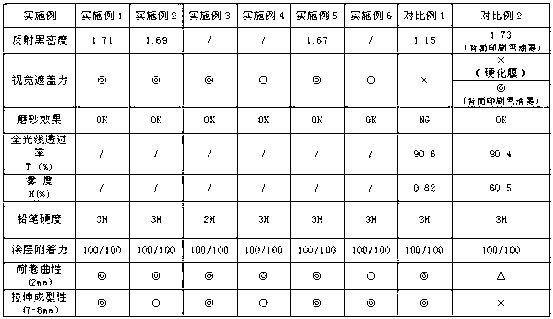

Examples

Embodiment 1

[0036] Aliphatic urethane acrylate prepolymer UXE1000 45.0 parts,

[0037] Propoxylated pentaerythritol tetraacrylate EM2421 5.0 parts,

[0038] Black polyurethane microspheres C-800 B 15.0 parts,

[0039] Photoinitiator 184 2.0 parts,

[0040] Levaslip 432 2.0 servings,

[0041] Butanone 15.5 parts,

[0042] 15.5 parts of ethyl cellosolve,

[0043] To 45 parts of aliphatic urethane acrylate prepolymer (manufactured by Huayao Chemical (Wuxi) Co., Ltd., trade name: UXE1000) and 5.0 parts of propoxylated pentaerythritol tetraacrylate monomer (manufactured by Changxing Chemical Industry Co., Ltd. , trade name: EM2421), add 15 parts of black polyurethane microspheres (Negami Industry, product model: C-800 B, particle size 7 μm) for dispersion, and then add 2.0 parts of polydimethylsiloxane skeleton structure leveling agent (manufactured by Deqian (Shanghai) Chemical Co., Ltd.; trade name: Levaslip 432), and added 2.0 parts of photoinitiator (manufactured by Tianjin Tianjiao C...

Embodiment 2

[0046] Polyester acrylate prepolymer 6311-100 32.0 parts,

[0047] Ethoxylated pentaerythritol tetraacrylate monomer EM2411 8.0 parts,

[0048] Black acrylic microspheres C-400 B 25.0 parts,

[0049] Photoinitiator 1173 6.0 parts,

[0050] BYK 307 1.0 parts,

[0051] Butanone 14.0 parts,

[0052] 14.0 parts of methyl isobutyl ketone,

[0053]To 32.0 parts of polyester acrylate prepolymer (manufactured by Changxing Chemical Industry Co., Ltd., trade name: 6311-100) and 8.0 parts of ethoxylated pentaerythritol tetraacrylate monomer (manufactured by Changxing Chemical Industry Co., Ltd., trade name : EM2411), add 25 parts of black acrylic microspheres (Negami Industry, product model: C-400 B, particle size 15 μm) for dispersion, and then add 1.0 parts of polyether-modified polydimethylsiloxane skeleton Structured leveling agent (manufactured by BYK Chemical Co., Ltd.; trade name: BYK 307), and add 6.0 parts of photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Lt...

Embodiment 3

[0056] Aliphatic polyurethane hexaacrylate prepolymer 6145-100 20.0 parts,

[0057] 19.5 parts of internal group-modified dipentaerythritol 6 acrylic resin DPCA-60,

[0058] Photoinitiator 184 7.0 parts,

[0059] Blue polyurethane microspheres F040-15 30.0 parts,

[0060] BYK 333 1.5 parts,

[0061] Butanone 11.0 parts,

[0062] 11.0 parts of toluene,

[0063] To 20.0 parts of aliphatic polyurethane hexaacrylate prepolymer (manufactured by Changxing Chemical Industry Co., Ltd., trade name: 6145-100) and 19.5 parts of endide-modified dipentaerythritol 6 acrylic resin (Chemical Chemical Industry (Wuxi) Co., Ltd., trade name: DPCA-60), add 30 parts of blue polyurethane microspheres (Negami Industry, product model: F040-15, particle size 7μm) for dispersion, and then add 1.5 parts of polydimethylsiloxane A leveling agent with an oxane skeleton structure (manufactured by BYK Chemicals; trade name: BYK 333), and 7.0 parts of a photoinitiator (manufactured by Tianjin Tianjiao Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com