Hub equipped with decorating ring and method for processing the same

A technology for decorative rings and wheel hubs, which is applied in the directions of wheels, wheel covers, transportation and packaging, etc., can solve the problems of easy loosening of stainless steel decorative rings, tearing of decorative rings, insufficient wrapping force of decorative rings, etc. The effect of loosening, maintaining high brightness and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

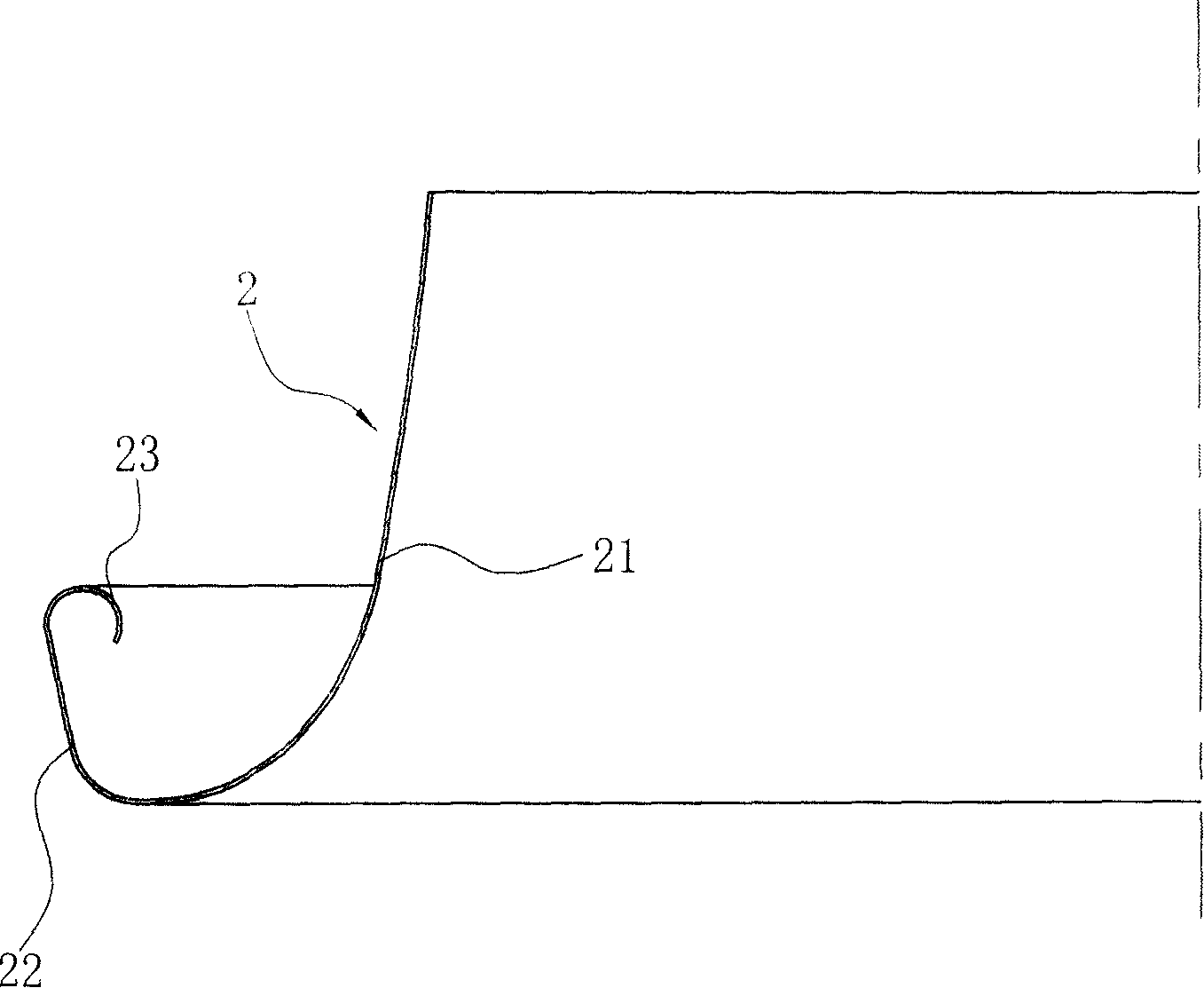

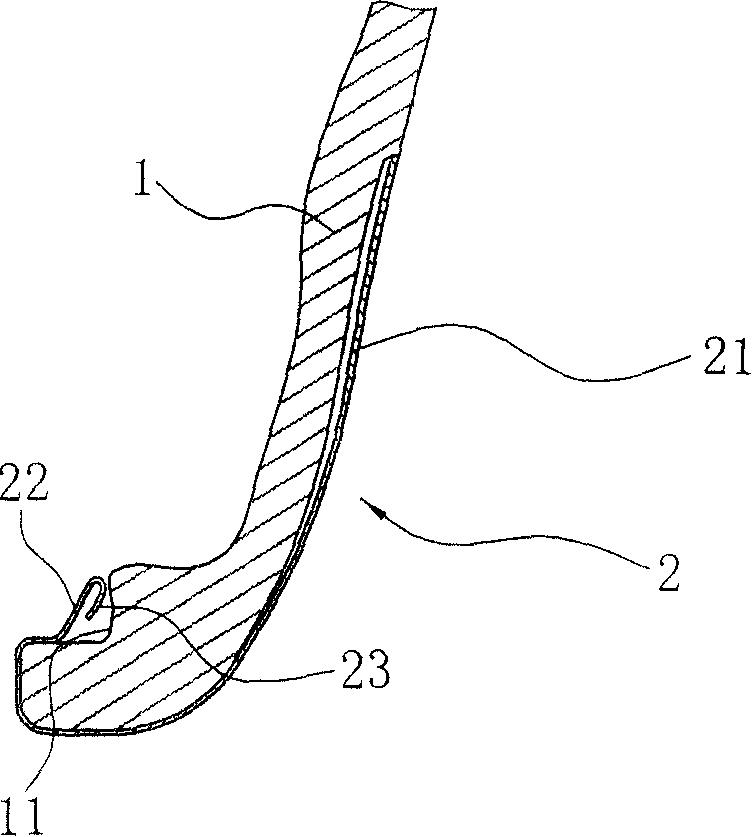

[0023] Such as figure 1 , 2 As shown, a wheel hub provided with a decorative ring includes a wheel hub 1 and a stainless steel decorative ring 2 coated on the surface of the rim part of the wheel hub 1. The stainless steel decorative ring 2 consists of a washbasin-shaped decorative wall 21 and a decorative The outer circumference of the wall 21 is composed of an inwardly curved curved edge 22, which is characterized in that: the upper end of the curved edge 22 has a double-layered bent edge 23 that is concave inward, and the bent edge 23 is squeezed The method is tightly wrapped with the surface 11 of the inner side step of the rim on the wheel hub 1.

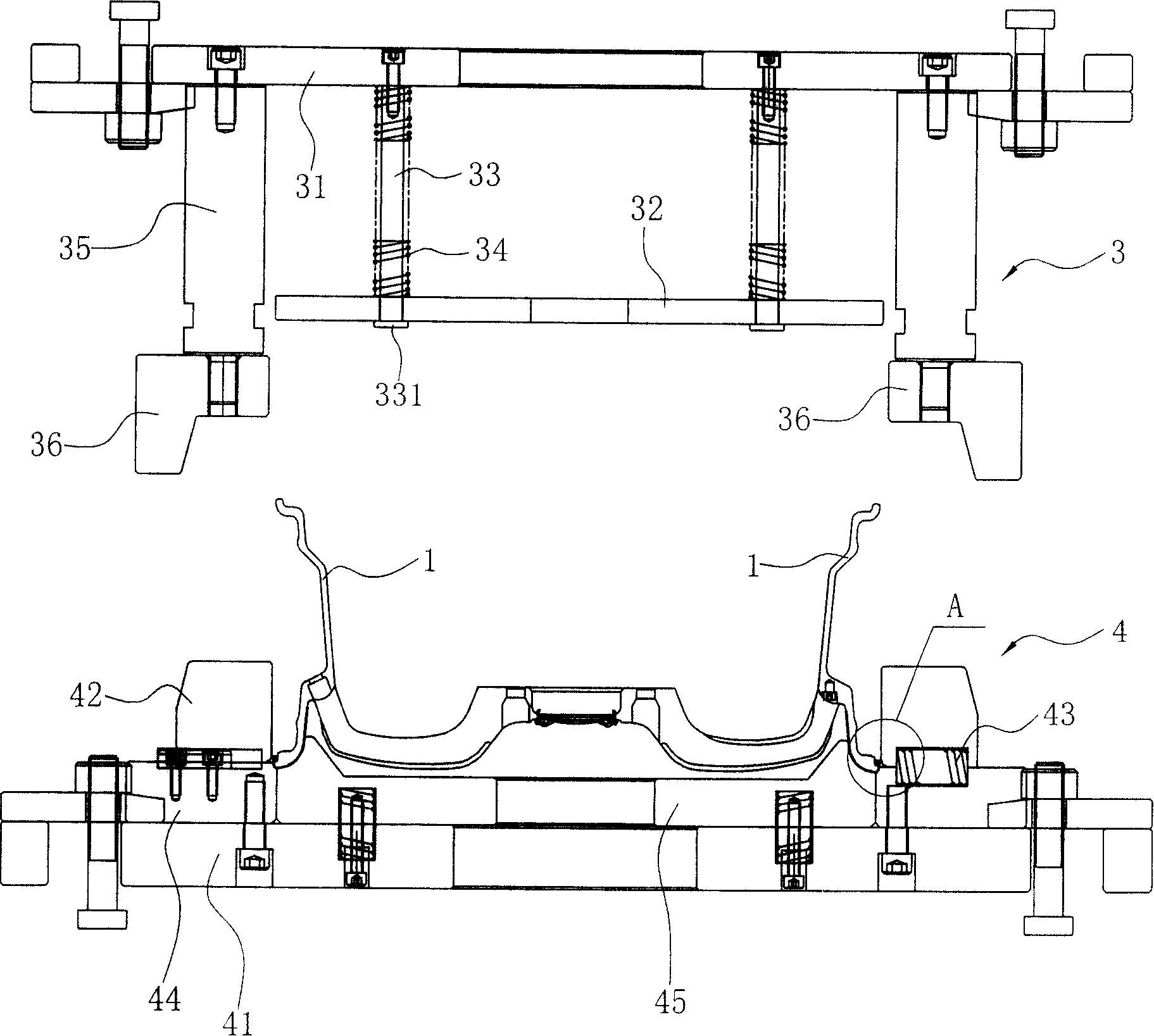

[0024] Such as Figure 3-7 As shown, a method for a wheel hub provided with a decorative ring, which includes the following steps: ①. According to the wheel hub 1 of different shapes and spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com