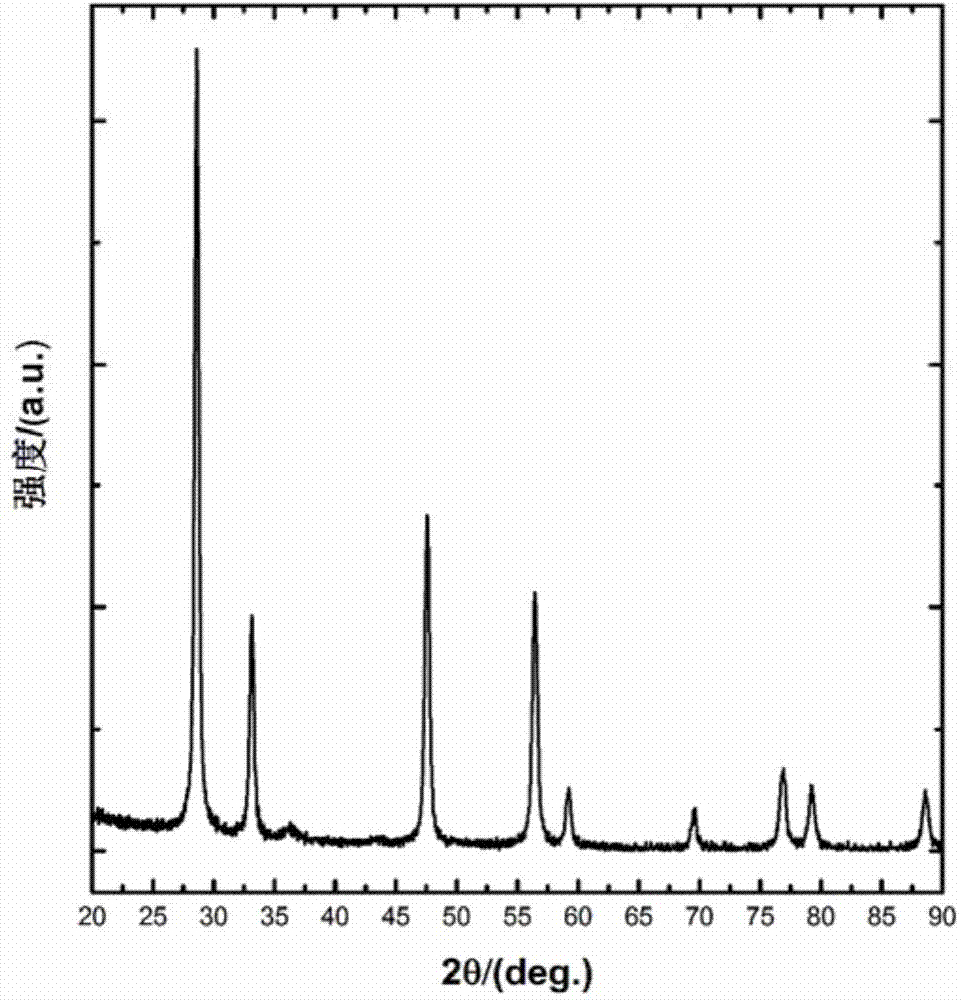

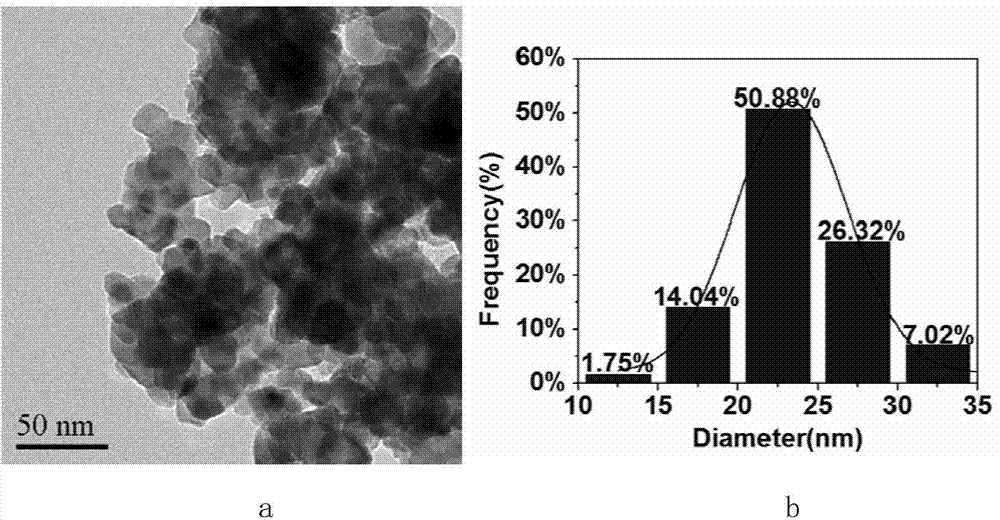

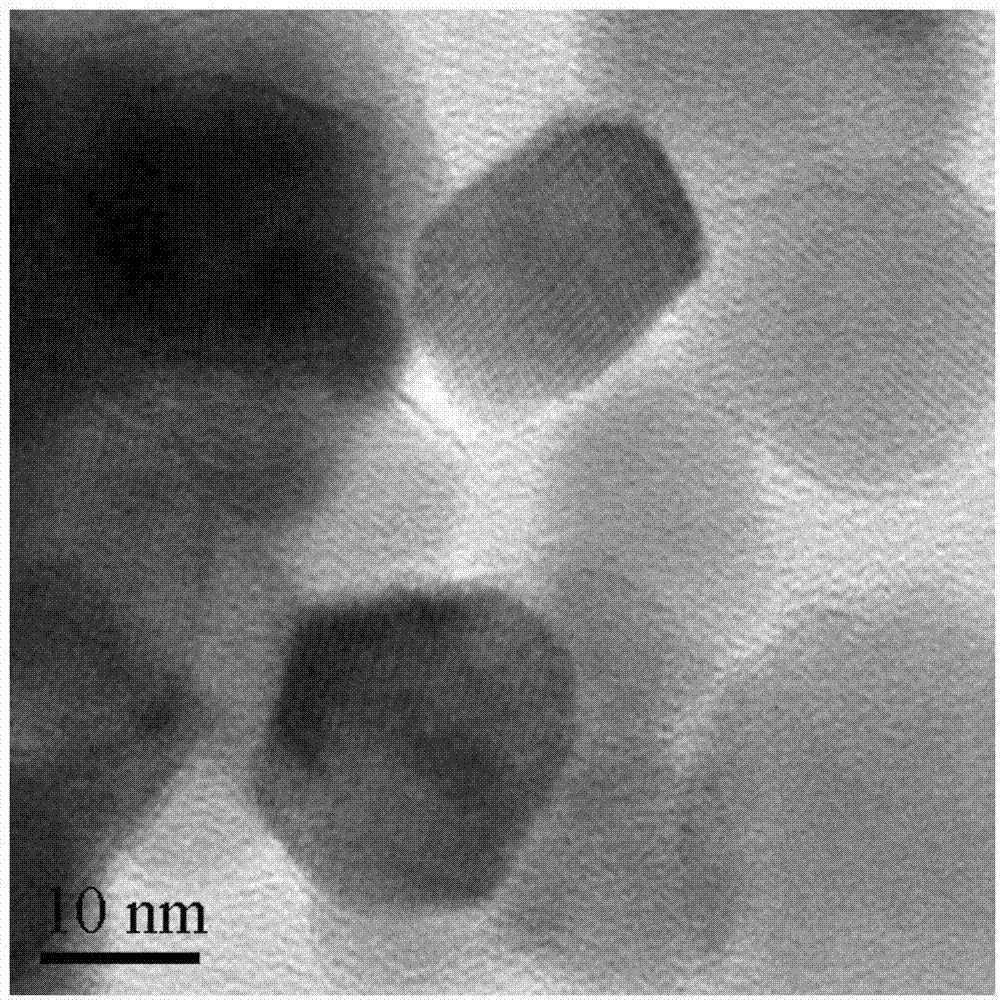

Preparation method of cubic lanthanum zirconate nanometer monocrystal

A nano single crystal, lanthanum zirconate technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of high calcination temperature, achieve the effects of lower calcination temperature, easy control of process parameters, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing cubic lanthanum zirconate nano single crystals, comprising the steps of:

[0030] 1) Preparation of hydroxide colloid (preparation of hydroxide precursor):

[0031] The zirconium oxychloride solution is mixed with the lanthanum nitrate solution to obtain a mixed solution in which the molar ratio of zirconium ions to lanthanum ions is 1:1, the concentration of zirconium ions is 0.2mol / L, and the concentration of lanthanum ions is 0.2mol / L;

[0032] The mixed solution is added to ammonia water with a volume concentration of 30% to 80% and stirred to make the pH of the system reach 8-11; stand and age for 2 hours to obtain a hydroxide colloid;

[0033] 2) Solid-liquid separation and washing: Pour off the aged supernatant, and remove impurities from the hydroxide colloid by centrifugal separation (or filter press washing), until the separated water cannot detect chloride ions with silver nitrate ( No precipitation was detected), and a semi-so...

Embodiment 2

[0041] A method for preparing cubic lanthanum zirconate nano single crystals, comprising the steps of:

[0042] 1) Preparation of hydroxide colloid (preparation of hydroxide precursor):

[0043] The zirconium oxychloride solution is mixed with the lanthanum nitrate solution to obtain a mixed solution in which the molar ratio of zirconium ions to lanthanum ions is 1:1, the concentration of zirconium ions is 1.0mol / L, and the concentration of lanthanum ions is 0.5mol / L;

[0044] The mixed solution is added to ammonia water with a volume concentration of 30% to 80% and stirred to make the pH of the system reach 8-11; stand and age for 2 hours to obtain a hydroxide colloid;

[0045] 2) Solid-liquid separation and washing: Pour off the aged supernatant, and remove impurities from the hydroxide colloid by centrifugal separation (or filter press washing), until the separated water cannot detect chloride ions with silver nitrate ( No precipitation was detected), and a semi-so...

Embodiment 3

[0052] A method for preparing cubic lanthanum zirconate nano single crystals, comprising the steps of:

[0053] 1) Preparation of hydroxide colloid (preparation of hydroxide precursor):

[0054] The zirconium oxychloride solution is mixed with the lanthanum nitrate solution to obtain a mixed solution in which the molar ratio of zirconium ions to lanthanum ions is 1:1, the concentration of zirconium ions is 0.5mol / L, and the concentration of lanthanum ions is 0.5mol / L;

[0055] Add it into ammonia water with a volume concentration of 30% to 80% and stir to make the pH of the system reach 8-11; leave it to stand for 2 hours to obtain a hydroxide colloid;

[0056] 2) Solid-liquid separation and washing: Pour off the aged supernatant, and remove impurities from the hydroxide colloid by centrifugal separation (or filter press washing), until the separated water cannot detect chloride ions with silver nitrate ( test without precipitation), and obtain a semi-solid high-viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com