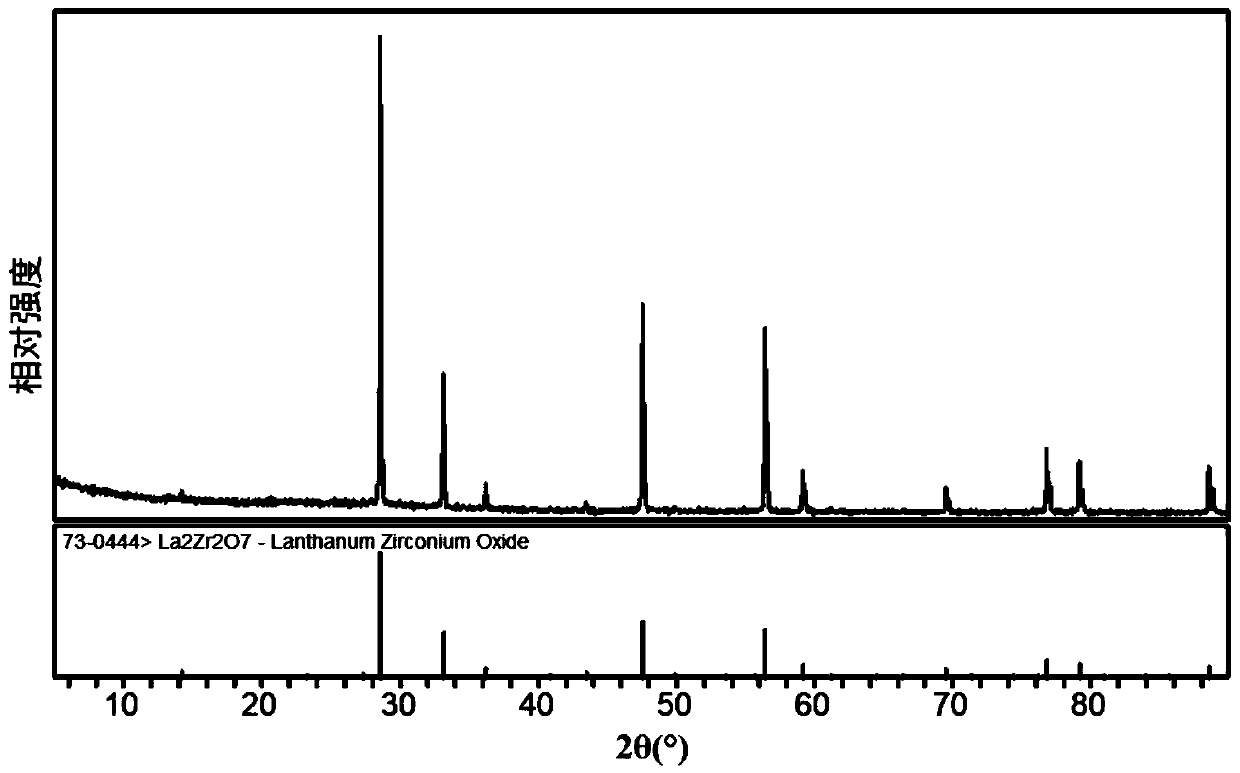

Preparation method of lanthanum zirconate spherical powder for thermal spraying

A spherical powder, lanthanum zirconate technology, applied in the field of functional material preparation, can solve the problems of high solid-phase synthesis temperature, high cost of metal salts, long production cycle, etc., to achieve low synthesis cost and avoid particle growth , conversion efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Lanthanum oxide and zirconium oxide are used as initial raw materials, wherein the purity of lanthanum oxide is 99.8wt.%, and the purity of zirconia is 99.99wt.%. Weigh 34.16g of lanthanum oxide, 25.84g of zirconia, 33.28g of potassium chloride, and 26.72g of sodium chloride into the ball mill jar together with 240g of zirconia balls and 240mL of ethanol, and mill at 480r / min for 2 hours. After taking it out and drying it, put it into a muffle furnace and raise the temperature to 1200°C at 5°C / min for 4 hours, then cool down to room temperature with the furnace.

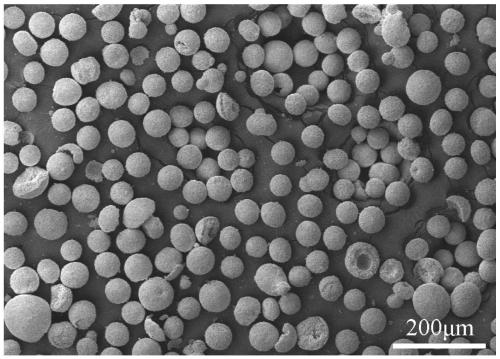

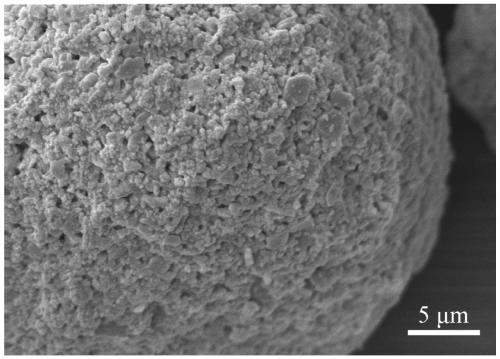

[0029] 2) wash with deionized water and suction filter, repeat 3 times, add 25g of 10wt.% PVA solution to the filter cake and stir evenly to obtain a slurry, use airflow spray drying equipment to granulate, the inlet temperature is 240 ° C, and the outlet temperature is 120°C;

[0030] 3) Put the powder obtained after spray granulation into a muffle furnace and raise the temperature at 3°C / min to 1300°C fo...

Embodiment 2

[0034] 1) Lanthanum oxide and zirconium oxide are used as initial raw materials, wherein the purity of lanthanum oxide is 99.8wt.%, and the purity of zirconia is 99.99wt.%. Weigh 34.16g of lanthanum oxide, 25.84g of zirconia, 33.28g of potassium chloride, and 26.72g of sodium chloride into the ball mill jar together with 240g of zirconia balls and 240mL of ethanol, and mill at 480r / min for 2 hours. After taking it out and drying it, put it into a muffle furnace and raise the temperature to 1100°C at 5°C / min for 8 hours, then cool down to room temperature with the furnace.

[0035] 2) Wash with deionized water and suction filter, repeat 3 times, add 60g of 10wt.% PVA solution to the filter cake and stir evenly to obtain a slurry, use spray drying equipment to granulate, the inlet temperature is 240°C, and the outlet temperature is 120°C ;

[0036] 3) Put the powder obtained after spray granulation into a muffle furnace and raise the temperature at 3°C / min to 1400°C for 3 hours...

Embodiment 3

[0038] 1) Lanthanum oxide and zirconium oxide are used as initial raw materials, wherein the purity of lanthanum oxide is 99.8wt.%, and the purity of zirconia is 99.99wt.%. Weigh 34.16g of lanthanum oxide, 25.84g of zirconia, 33.28g of potassium chloride, and 26.72g of sodium chloride into the ball mill jar together with 240g of zirconia balls and 240mL of ethanol, and mill at 480r / min for 2 hours. After taking it out and drying it, put it into a muffle furnace and raise the temperature to 1200°C at 5°C / min for 4 hours, then cool down to room temperature with the furnace.

[0039] 2) Wash with deionized water and suction filter, repeat 3 times, add 25g of 10wt.% PVA solution to the filter cake and stir evenly to obtain a slurry, use spray drying equipment to granulate, the inlet temperature is 240°C, and the outlet temperature is 120°C ;

[0040] 3) Put the powder obtained after spray granulation into a muffle furnace and raise the temperature at 3°C / min to 1400°C for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com