Method for preparing porous lanthanum zirconate block

A technology for lanthanum zirconate and porous blocks, which is applied in ceramic products, applications, household appliances, etc., can solve the problems that the preparation method of lanthanum zirconate porous blocks has not been reported in patents, etc., and achieves low price, simple process, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

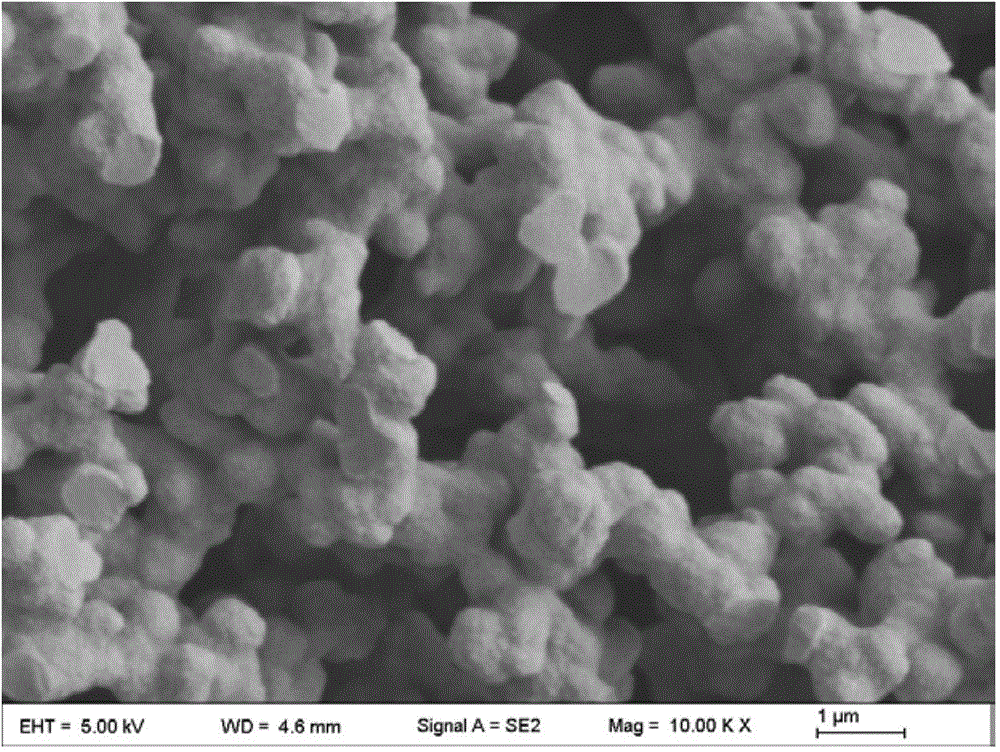

Embodiment 1

[0032] Embodiment 1. A method for preparing a porous lanthanum zirconate block. The zirconium inorganic salt is selected from zirconium oxychloride, the lanthanum inorganic salt is selected from lanthanum chloride, propylene oxide (PO) is used as a gel accelerator, and polyoxyethylene is used as a phase separation agent. Inducer, formamide is a drying control chemical additive, the surface modifier solution is an ethanol solution of ethyl orthosilicate (the volume fraction of ethyl orthosilicate is 20%), and the low surface tension solvent is dehydrated alcohol; wherein each substance The molar ratio of is as follows:

[0033] Zirconium oxychloride: lanthanum chloride: polyoxyethylene: formamide: propylene oxide = 1:0.8:0.0002:0.5:1;

[0034] Then proceed to the following steps in sequence:

[0035] 1) Dissolve zirconium oxychloride, lanthanum chloride and polyoxyethylene in an alcohol-water solvent, and stir magnetically for 3 hours to obtain a transparent solution; the alco...

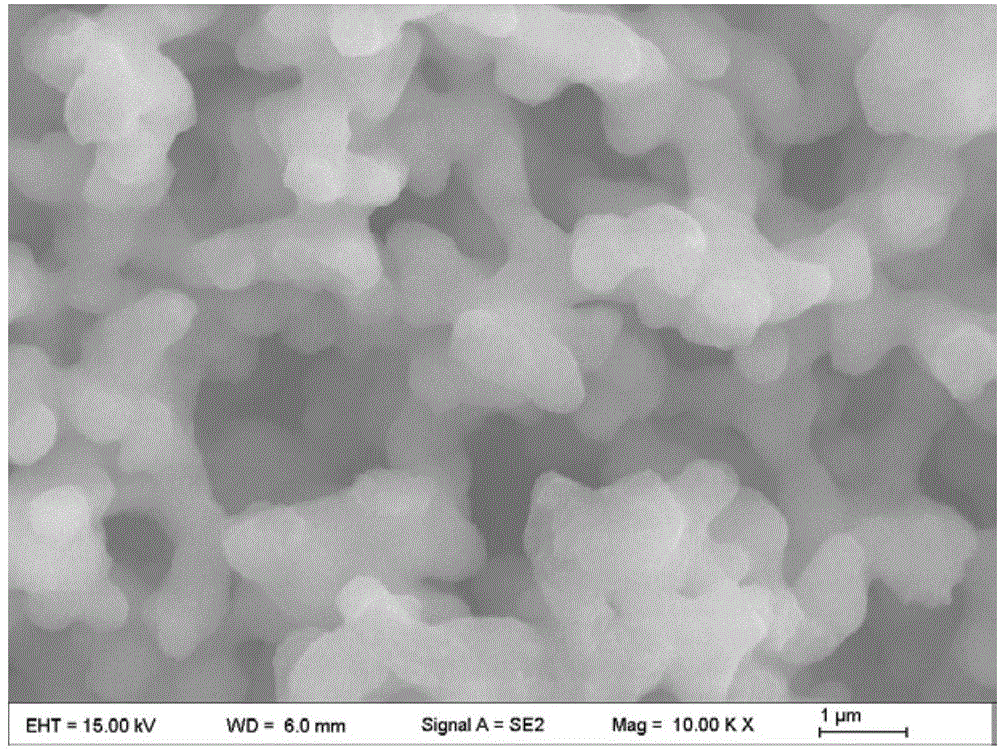

Embodiment 2

[0041] Embodiment 2, a preparation method of a lanthanum zirconate porous block, the zirconium inorganic salt is selected from zirconyl nitrate, the lanthanum inorganic salt is selected from lanthanum nitrate, propylene oxide is used as a gel accelerator, and polyvinylpyrrolidone (PVP) is used as a phase separation inducer agent, N-methylformamide is a drying control chemical additive, the surface modifier solution is an ethanol solution of trimethylchlorosilane (the volume fraction of trimethylchlorosilane is 15%), and the low surface tension solvent is cyclohexane; Wherein the molar ratio of each substance is as follows:

[0042]Zirconyl nitrate: lanthanum nitrate: polyvinylpyrrolidone: N-methylformamide: propylene oxide = 1:1.2:0.0005:0.9:1.4.

[0043] Then proceed to the following steps in sequence:

[0044] 1) Dissolving zirconium oxynitrate, lanthanum nitrate and polyvinylpyrrolidone in an alcohol-water solvent, and magnetically stirring for 4 hours to a transparent sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com