Method for preparing silver carbon nanotube and lanthanum zirconate composite electric contact material

A technology of electrical contact materials and carbon nanotubes, applied in contacts, circuits, electric switches, etc., can solve the problems of difficult plastic processing, brittle fracture, plasticity and strength of materials that need to be further improved, and improve plastic processing and performance. Effect of stabilizing and improving plastic workability and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

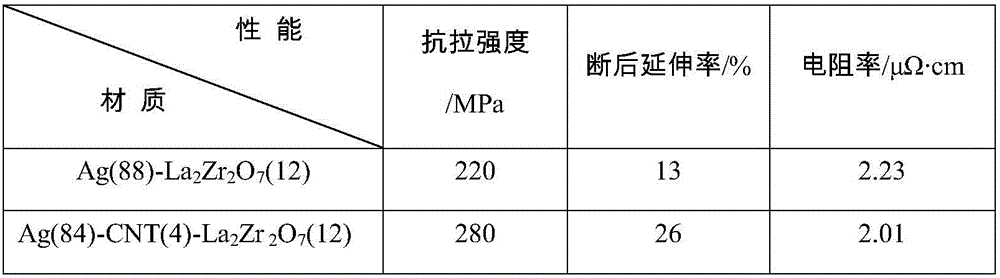

Examples

specific Embodiment 1

[0028] (1) Proportionally weigh zirconium nitrate and lanthanum nitrate with a molar ratio of 1:1 as raw materials, add to deionized water to dissolve completely, then move to a volumetric flask to constant volume, and configure a total concentration of 0.5mol / L Colorless transparent solution;

[0029] (2) Press n(Zr 4+ +La 3+ ):n (citric acid) molar ratio is 1:1.5 Weigh corresponding citric acid, add in the above-mentioned transparent solution, add the ammonia solution of mass concentration 25%~28% in the mixed solution, adjust pH to 7, and Continue magnetic stirring at room temperature for 3 hours; then settle for 24 hours, remove the supernatant, and dry at 80°C to obtain powder;

[0030] (3) Grinding the dried powder, passing through a 200-mesh sieve, and sintering at 900° C. for 5 hours to obtain the corresponding nano-powder of lanthanum zirconate;

[0031] (4) Using lanthanum zirconate nanopowder, carbon nanotube powder and silver powder as raw materials, according t...

specific Embodiment 2

[0034] (1) Proportionally weigh zirconium nitrate and lanthanum nitrate with a molar ratio of 1:1 as raw materials, add to deionized water to dissolve completely, then move to a volumetric flask to constant volume, and configure a total concentration of 0.5mol / L Colorless transparent solution;

[0035] (2) Press n(Zr 4+ +La 3+ ): n (citric acid) molar ratio is 1:1.5 Weigh corresponding citric acid, add in the above-mentioned transparent solution, dropwise add the ammonia solution of mass concentration 25%~28% in the mixed solution, adjust pH to 8, and Continue magnetic stirring at room temperature for 3 hours; then settle for 24 hours, remove the supernatant, and dry at 80°C to obtain powder;

[0036] (3) Grinding the dried powder, passing through a 200-mesh sieve, and sintering at 1000° C. for 4 hours to obtain the corresponding nano-powder of lanthanum zirconate;

[0037] (4) With lanthanum zirconate nanopowder, carbon nanotube powder and silver powder, according to 14wt....

specific Embodiment 3

[0040] (1) Proportionally weigh zirconium nitrate and lanthanum nitrate with a molar ratio of 1:1 as raw materials, add to deionized water to dissolve completely, then move to a volumetric flask to constant volume, and configure a total concentration of 0.5mol / L Colorless transparent solution;

[0041](2) Weigh the corresponding citric acid according to the n(Zr4++La3+):n(citric acid) molar ratio of 1:1.5, add it to the above transparent solution, and add dropwise to the mixed solution with a mass concentration of 25% to 28% ammonia solution, adjust the pH to 9, and continue magnetic stirring at room temperature for 3 hours; then settle for 24 hours, remove the supernatant, and dry at 80°C to obtain a powder;

[0042] (3) Grinding the dried powder, passing through a 200-mesh sieve, and sintering at 1200° C. for 3 hours to obtain the corresponding nano-powder of lanthanum zirconate;

[0043] (4) With lanthanum zirconate nanopowder, carbon nanotube powder and silver powder, acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com