High-purity and uniform-morphology lanthanum zirconate gadolinium powder and transparent ceramic preparation method

A lanthanum gadolinium zirconate, high-purity technology is applied in the field of optically functional transparent ceramic materials, which can solve the problems of product yield limitation, difficulty in mass production, atmospheric environmental pollution, etc., and achieves simple and controllable technological process and operation, and low cost. , The effect of high sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

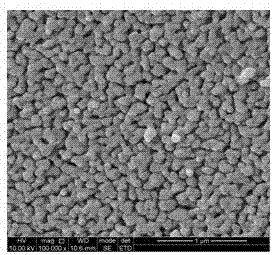

[0031] Embodiment 1: In this embodiment, a preparation method of a lanthanum-gadolinium zirconate powder and a transparent ceramic with high purity and uniform appearance is as follows:

[0032] (1) Gd(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O, ZrOCl 2 ·8H 2 O was dissolved in deionized water and its cation concentration was calibrated, according to Gd 3+ , La 3+ with Zr 4+ The molar ratio of the mixture is measured at a composition ratio of 1:1:2, and is mixed with a mixed salt solution; the mixed salt solution is titrated into the ammonia precipitant solution to a pH value of 10.8 to obtain a mixed solution;

[0033] (2) After aging the mixed solution for 24 hours, carry out suction filtration, and the precipitate filtered out is first washed 3 times with deionized water, and then washed 3 times with absolute ethanol to obtain a colloidal precipitate, which is placed in In an anhydrous ethanol medium equivalent to 1 times the volume ratio of the precipitate, stir evenl...

Embodiment 2

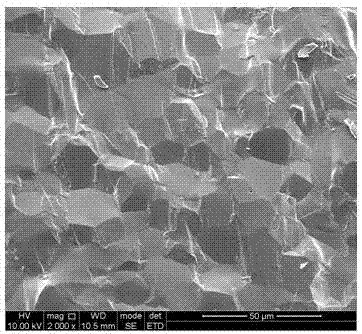

[0040] Embodiment 2: In this embodiment, a preparation method of a lanthanum-gadolinium zirconate powder with high purity and uniform appearance and transparent ceramics thereof is as follows:

[0041] (1) Gd(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O, ZrOCl 2 ·8H 2 O was dissolved in deionized water and its cation concentration was calibrated, according to Gd 3+ , La 3+ with Zr 4+ The molar ratio of the mixture is measured at a composition ratio of 1:1:2, and is mixed with a mixed salt solution; the mixed salt solution is titrated into the ammonia precipitant solution to a pH value of 11.2 to obtain a mixed solution;

[0042] (2) After aging the mixed solution for 30 hours, carry out suction filtration, and the precipitate filtered out is first washed 4 times with deionized water, and then washed 3 times with absolute ethanol to obtain a colloidal precipitate, which is placed in In an anhydrous ethanol medium equivalent to 1.5 times the volume of the precipitate, stir ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com