Cerium-doped lanthanum zirconate nano powder and preparation method thereof

A technology of nano-powder and lanthanum zirconate, which is applied in the direction of nano-technology, can solve problems such as unfavorable industrial production, hard agglomerates of powder, and affecting material properties, so as to facilitate large-scale industrial production, prevent agglomeration and growth, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

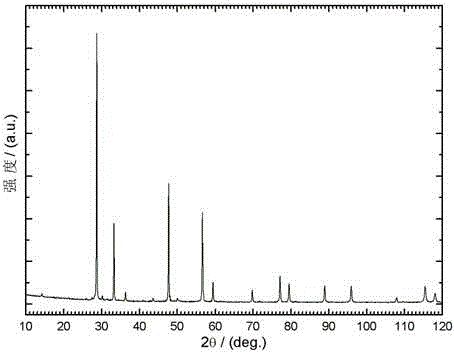

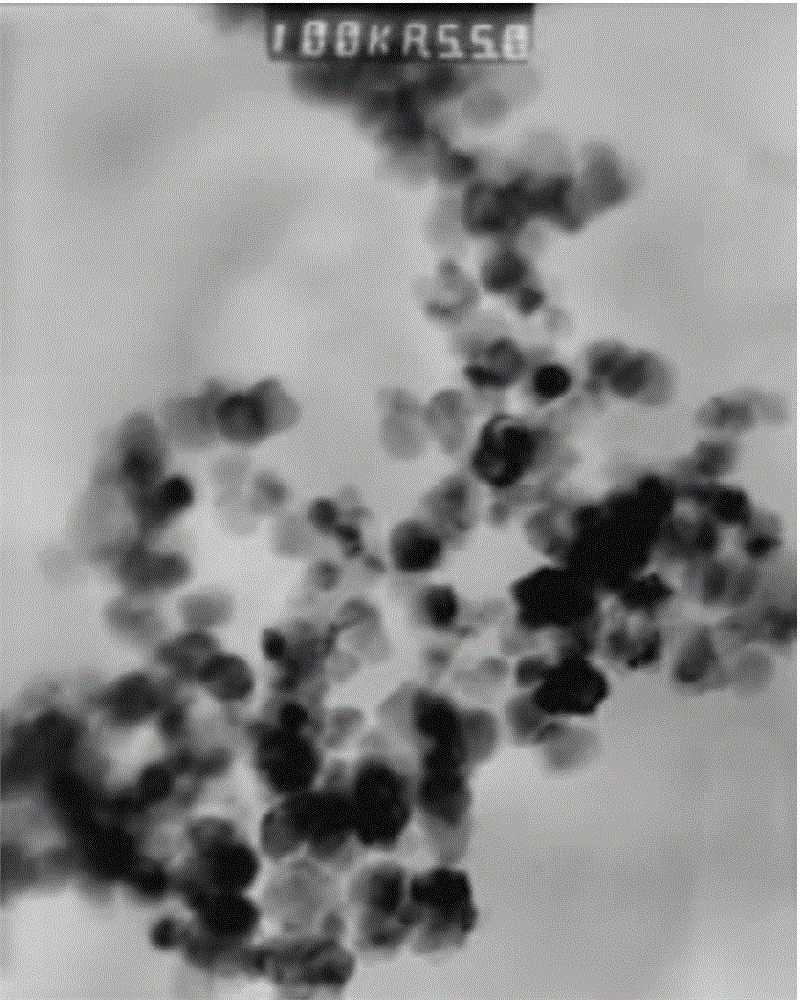

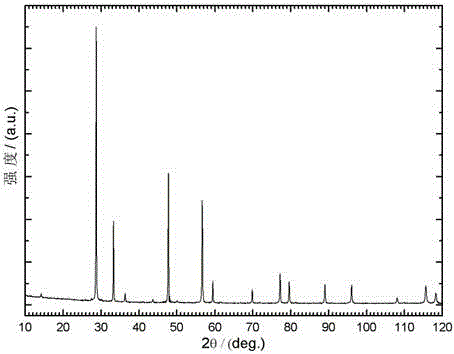

Image

Examples

Embodiment 1

[0036] 1) Preparation of hydroxide colloid:

[0037]Zirconium oxychloride solution and cerium nitrate solution are mixed, and preparation obtains the mixed solution of zirconium oxychloride solution and cerium nitrate solution; Then mixed solution and lanthanum nitrate solution are mixed, and the mol ratio that obtains cerium ion, zirconium ion and lanthanum ion is 1: 19:20, the concentration of cerium ion is 0.012mol / L, the concentration of zirconium ion is 0.228mol / L, the mixed solution of lanthanum ion concentration is 0.24mol / L;

[0038] Add ammonia water with a volume concentration of 30%~70% and stir to make the pH value of the system reach 8-10; then stand and age for more than 12 hours to obtain hydroxide colloid;

[0039] 2) Solid-liquid separation and washing: Pour off the hydroxide supernatant, separate and wash the hydroxide colloid through an inorganic ceramic membrane to remove impurities, until the separated water cannot detect chloride ions with silver nitrate ...

Embodiment 2

[0047] 1) Preparation of hydroxide colloid:

[0048] Prepare a mixed solution of cerium nitrate, zirconium oxychloride and lanthanum chloride, wherein the molar ratio of cerium ion, zirconium ion and lanthanum ion is 1:9:10, the concentration of cerium ion is 0.05mol / L, and the concentration of zirconium ion is 0.45 mol / L, the concentration of lanthanum ion is 0.5mol / L;

[0049] Add ammonia water with a volume concentration of 35% and stir to make the pH value of the system reach 8; then stand and age for more than 12 hours to obtain a hydroxide colloid;

[0050] 2) Solid-liquid separation and washing: Pour off the hydroxide supernatant, remove the impurities from the hydroxide colloid by centrifugation, and wash until no chloride ions are found in the washing solution with silver nitrate, and use a centrifuge to concentrate to obtain Semi-solid high-viscosity hydroxide gel with a solid content of 8%~20%;

[0051] 3) Dehydration: Mix the semi-solid high-viscosity hydroxide g...

Embodiment 3

[0057] 1) Preparation of hydroxide colloid: prepare a mixed solution of zirconium oxychloride, ceric sulfate, and lanthanum chloride, wherein the molar ratio of cerium ions, zirconium ions, and lanthanum ions in the mixed solution is 1:3:4, and the concentration of cerium ions is 0.175mol / L, the concentration of zirconium ions is 0.525 mol / L, and the concentration of lanthanum ions is 0.7 mol / L; add ammoniacal liquor with a volume concentration of 70% to the mixed solution and stir to make the pH value of the system reach 10; then Static aging makes hydroxide colloid;

[0058] 2) Solid-liquid separation and washing: Pour off the hydroxide supernatant, remove impurities from the hydroxide colloid by centrifugation and wash until no chloride ions are found in the washing solution with silver nitrate, and filter with a filter press Concentrate to obtain a semi-solid high-viscosity hydroxide gel;

[0059] 3) Dehydration: mix the semi-solid high-viscosity hydroxide gel with n-prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com