Chromium-free and environment-friendly catalyst for synthesis of 3,3,3-trifluoropropene by gas-phase fluorination

A technology of trifluoropropene and catalyst, which is applied in the fields of physical/chemical process catalyst, organic chemistry, dehydrohalogenation preparation, etc., can solve the problems of ecological environment pollution, human health threat, etc., and achieves good high temperature anti-sintering ability and anti-sintering performance. Superior and improved mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

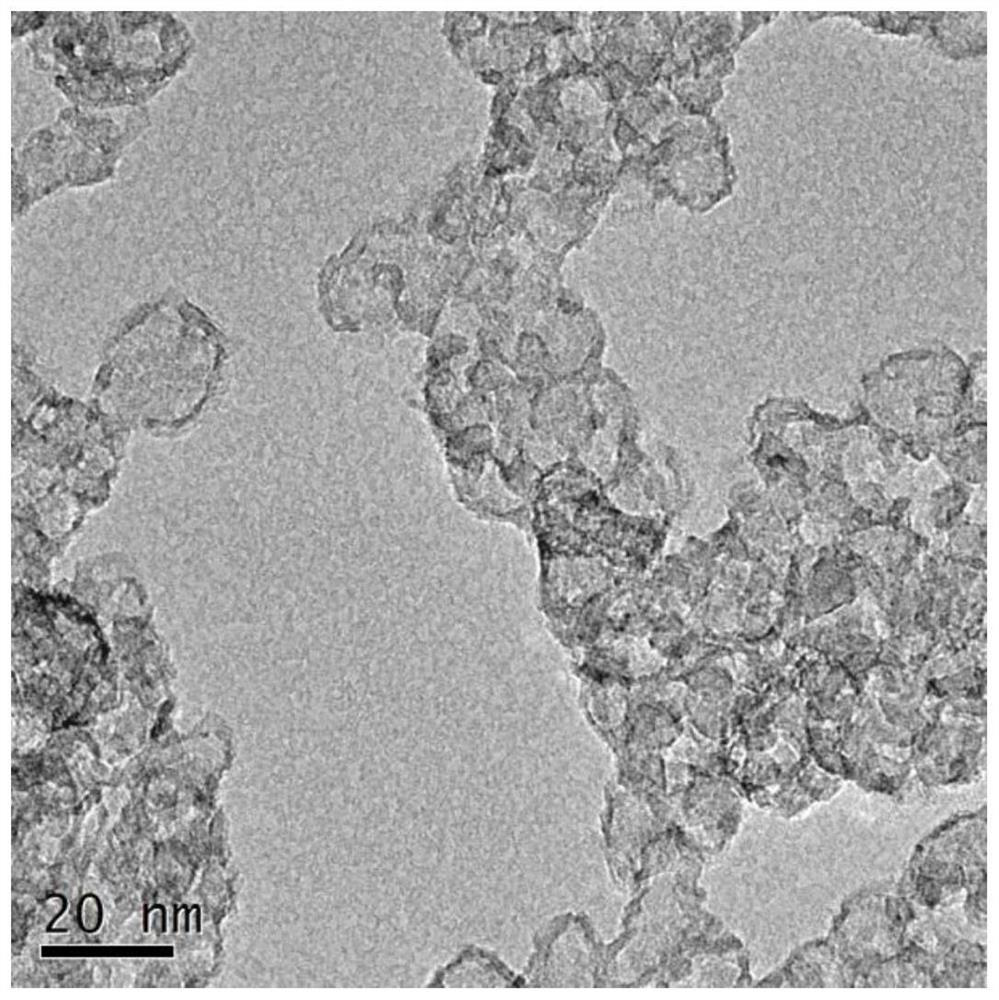

[0027] Embodiment 1: prepare M / MgF 2 catalyst

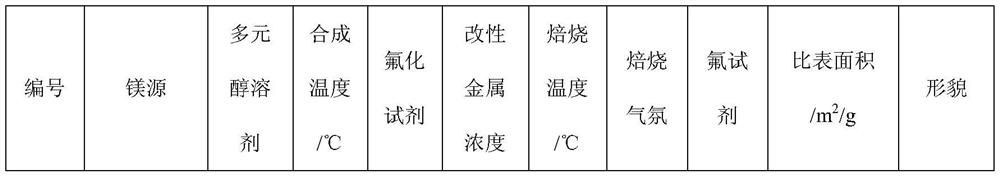

[0028] Dissolve 1.0M magnesium source and 0.01-0.1M modified metal ions in 50mL polyol solvent, and add the fluorinating reagent dropwise to the above solution under stirring at 150-240°C for 15 minutes. Stir again for 6-12h to obtain M / MgF 2 Dry gel; then calcined in an air or hydrogen atmosphere at 300-500°C for more than 5 hours, and finally fluorinated the calcined material at a temperature of 150-400°C to obtain a catalyst. The fluorine reagents are gaseous hydrogen fluoride and dichlorodifluoromethane , one chlorodifluoromethane, one chlorotrifluoromethane any one. The textural properties of magnesium fluoride prepared under different magnesium sources, polyol solvents, coagulants, fluorinating reagents, and calcination temperatures are shown in Table 1.

[0029] The physicochemical property result of the magnesium fluoride-based catalyst of table 1 embodiment 1

[0030]

[0031]

Embodiment 2

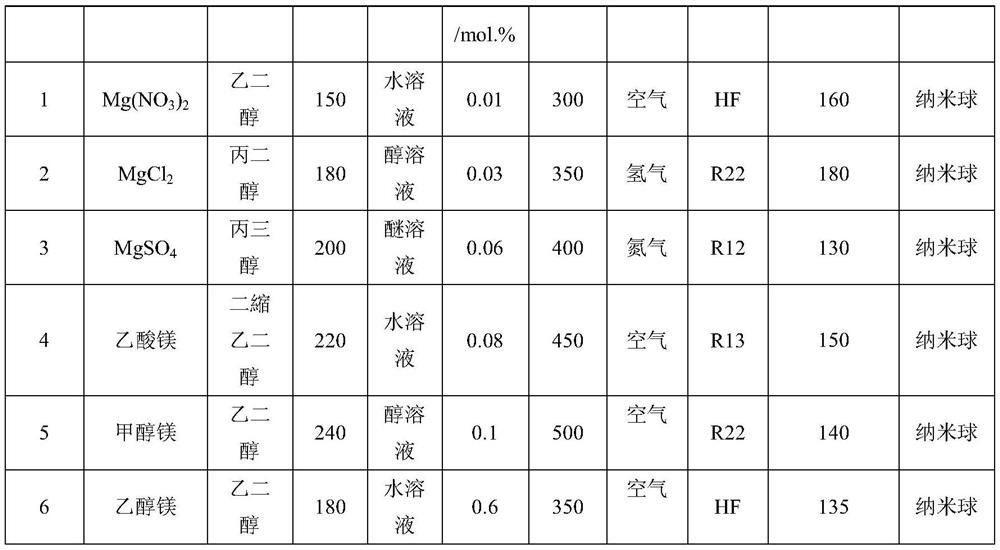

[0033] Adopt the same method to prepare M / MgF in embodiment 1 2 Catalyst, apply it to the gas-phase fluorination of 1,1,1,3-tetrachloropropane to synthesize HFO-1243f. After running for 12 hours, the reaction results are as follows:

[0034] The reaction evaluation result of the magnesium fluoride-based catalyst of table 2 embodiment 2

[0035]

Embodiment 3

[0037] Adopt the same method to prepare M / MgF in embodiment 1 2 Catalyst, apply it to the gas-phase fluorination of 1,1,1,3-tetrachloropropane to synthesize HFO-1243f. After running for 12 hours, the reaction results are as follows:

[0038] The reaction evaluation result of the magnesium fluoride-based catalyst of table 3 embodiment 3

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com