A kind of non-stoichiometric zinc-aluminum spinel and its preparation method

A non-stoichiometric ratio, zinc-aluminum spinel technology, applied in chemical instruments and methods, inorganic chemistry, zinc compounds, etc., can solve the problem of limiting the performance and application of zinc-aluminum spinel, and the difficulty in obtaining pure zinc-aluminum spinel , Zinc-aluminum spinel grain size is large and other problems, to achieve the effect of adjustable zinc-aluminum molar ratio, low cost, high purity and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

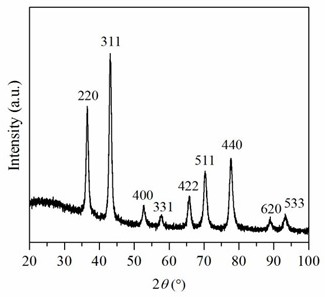

Embodiment 1

[0023] Weigh 6.7423g Zn(NO 3 ) 2 ·6H 2 O and 8.5019g Al(NO 3 ) 3 9H 2 O and dissolved in 100 mL deionized water to prepare a zinc-aluminum mixed solution. Press Na 2 CO 3 The molar mass of Al(NO 3 ) 3 9H 2 Weigh 1.2011g of anhydrous Na with 0.5 times the molar amount of O 2 CO 3 , dissolved in 100 mL deionized water to prepare Na 2 CO 3 solution. Weigh 20g NaOH, dissolve it in 250mL deionized water, and prepare 2 mol / L NaOH solution. At room temperature and under magnetic stirring, the zinc-aluminum mixed solution was added dropwise to Na 2 CO 3 solution. At the same time, NaOH solution was added dropwise to Na 2 CO 3 solution, adjust the NaOH solution drop rate with a peristaltic pump to keep the pH of the solution = 10 ± 0.5. After the dropwise addition, it was left to age for 24 h, then suction filtered, and washed with deionized water until the pH of the filtrate = 7±0.2. Afterwards, the obtained solid was dried in an oven at 100 °C for 12 h to obtain ...

Embodiment 2

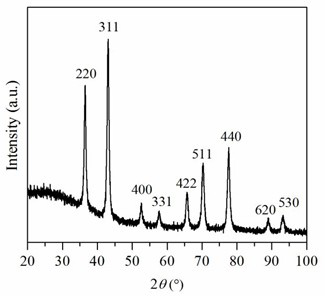

[0026] Weigh 8.3499g Zn(NO 3 ) 2 ·6H 2 O and 5.2646g Al(NO 3 ) 3 9H 2 O and dissolved in 100 mL deionized water to prepare a zinc-aluminum mixed solution. Press Na 2 CO 3 The molar mass of Al(NO 3 ) 3 9H 2 0.5 times the molar weight of O, weigh 0.7437g anhydrous Na 2 CO 3 , dissolved in 100 mL deionized water to prepare Na 2 CO 3 solution. Weigh 20g NaOH, dissolve it in 250mL deionized water, and prepare 2 mol / L NaOH solution. At room temperature and under magnetic stirring, the zinc-aluminum mixed solution was added dropwise to Na 2 CO 3 solution. At the same time, NaOH solution was added dropwise to Na 2 CO 3 solution, adjust the NaOH solution drop rate with a peristaltic pump to keep the pH of the solution = 10 ± 0.5. After the dropwise addition, it was left to age for 24 h, then suction filtered, and washed with deionized water until the pH of the filtrate = 7±0.2. Afterwards, the obtained solid was dried in an oven at 100 °C for 12 h to obtain zinc-al...

Embodiment 3

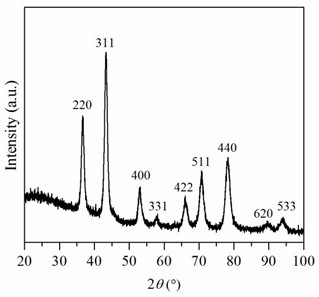

[0029] Weigh 9.0711g Zn(NO 3 ) 2 ·6H 2 O and 3.8128g Al(NO 3 ) 3 9H 2 O and dissolved in 100 mL deionized water to prepare a zinc-aluminum mixed solution. Press Na 2 CO 3 The molar mass of Al(NO 3 ) 3 9H 2 0.5 times the molar weight of O, weigh 0.5386g anhydrous Na 2 CO 3 , dissolved in 100 mL deionized water to prepare Na 2 CO 3 solution. Weigh 20g NaOH, dissolve it in 250mL deionized water, and prepare 2 mol / L NaOH solution. At room temperature and under magnetic stirring, the zinc-aluminum mixed solution was added dropwise to Na 2 CO 3 solution. At the same time, NaOH solution was added dropwise to Na 2 CO 3 solution, adjust the NaOH solution drop rate with a peristaltic pump to keep the pH of the solution = 10 ± 0.5. After the dropwise addition, it was left to age for 24 h, then suction filtered, and washed with deionized water until the pH of the filtrate = 7±0.2. Afterwards, the obtained solid was dried in an oven at 100 °C for 12 h to obtain zinc-al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com