A preparation method of nano samarium zirconate powder used for additive manufacturing feed

A technology of additive manufacturing and samarium zirconate, applied in the field of nano-powder preparation, can solve the problems of unavailable ceramic powder, complex process, unfavorable large-scale production, etc., achieve stable phase structure, less process flow, Ease of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] Embodiment 1: This embodiment is a method for preparing nano-samarium zirconate powder used for additive manufacturing feed, specifically carried out according to the following steps:

[0041] 1. Preparation of mixed slurry: mix and ball mill deionized water and nano-mixed powder for 12 hours to obtain mixed slurry I; the nano-mixed powder is nanometer Sm 2 o 3 with nano ZrO 2 A mixture of which, nano Sm 2 o 3 with nano ZrO 2 The mol ratio is 1:2; The mass fraction of deionized water in the mixed slurry I is 40%~50%;

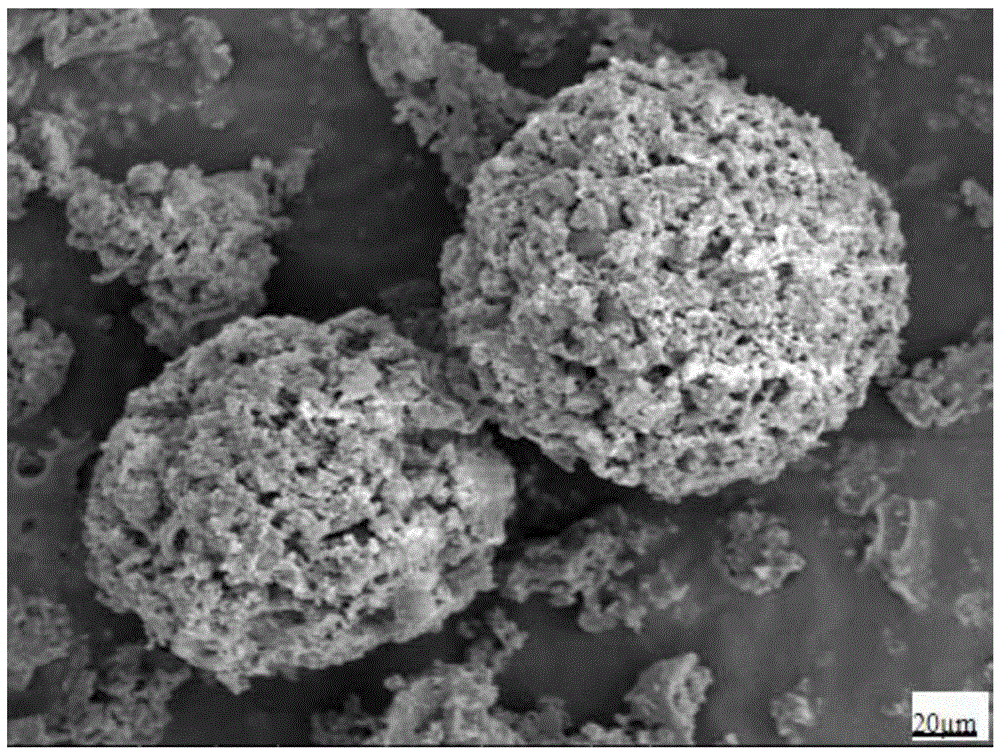

[0042] 2. Spray drying: spray-dry the obtained mixed slurry I to obtain mixed powder I; the rotational speed of the atomizing disc during the spray-drying is 24900r·min -1 ~25100r·min -1 , the inlet temperature is 217°C-223°C, the outlet air temperature is 109°C-111°C, and the slurry feeding rate is 5.1L·min -1 ~5.7L·min -1 ;

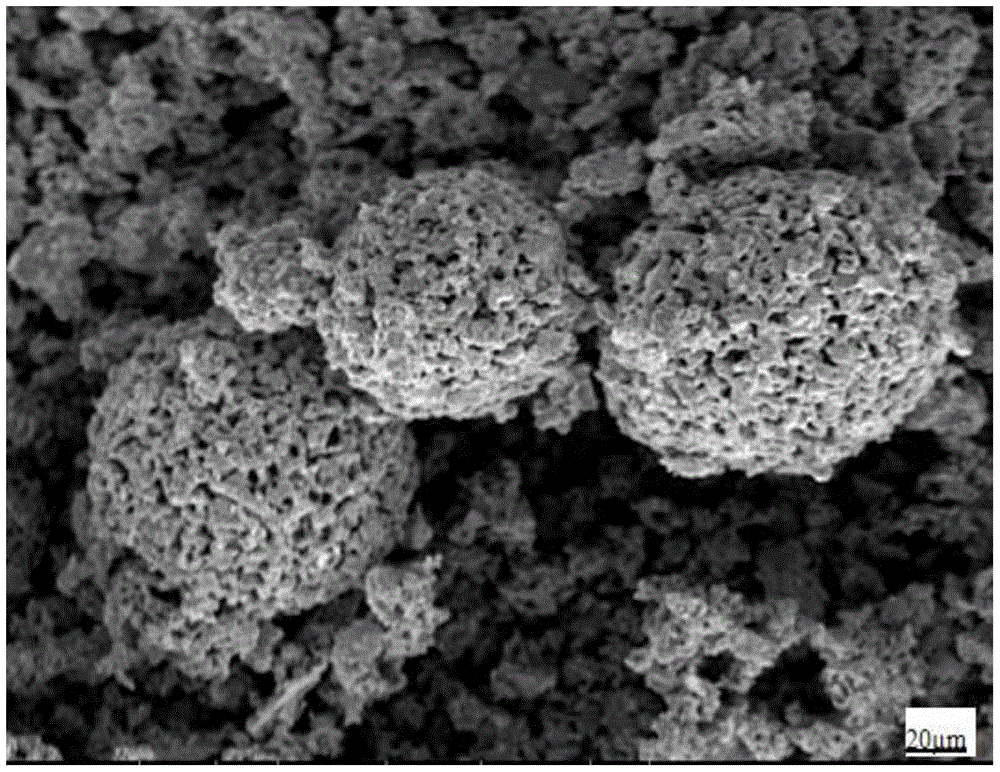

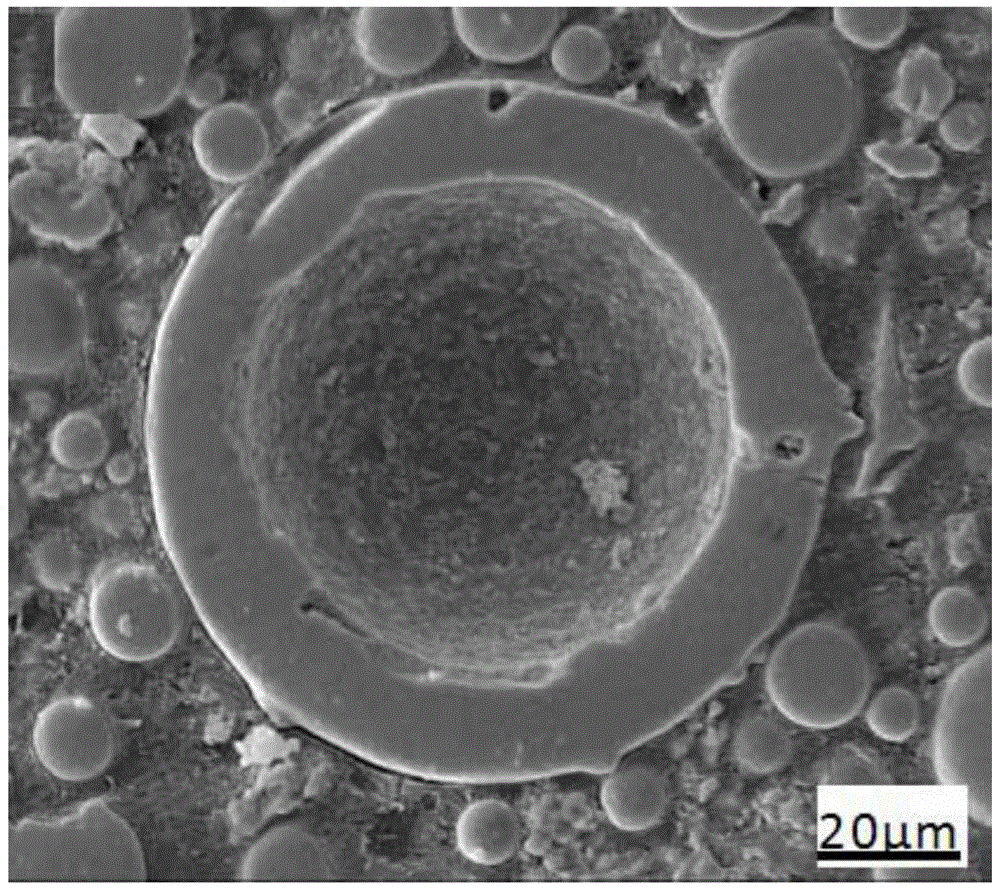

[0043] 3. High-temperature solid-phase sintering: The mixed powder I obtained in step 2 is subjected to high-temperature...

specific Embodiment approach 2

[0047] Specific embodiment two: the difference between this embodiment and specific embodiment one is: what the ball milling described in step one used is ZrO 2 Grinding balls. Others are the same as the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment two is: ZrO described in step one 2 The grinding ball is made of ZrO with a diameter of 7mm 2 Grinding balls, ZrO with a diameter of 8mm 2 Grinding balls and ZrO with a diameter of 10mm 2 Mixed grinding balls made by mixing grinding balls. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com