Angle-adjustable automatic paint spraying equipment

An automatic painting and angle adjustment technology, which is applied in the direction of architecture and building construction, can solve the problems of difficult adjustment of spraying angle, uneven paint film thickness, low spraying efficiency, etc., and achieve the effect of reasonable design and meeting spraying requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

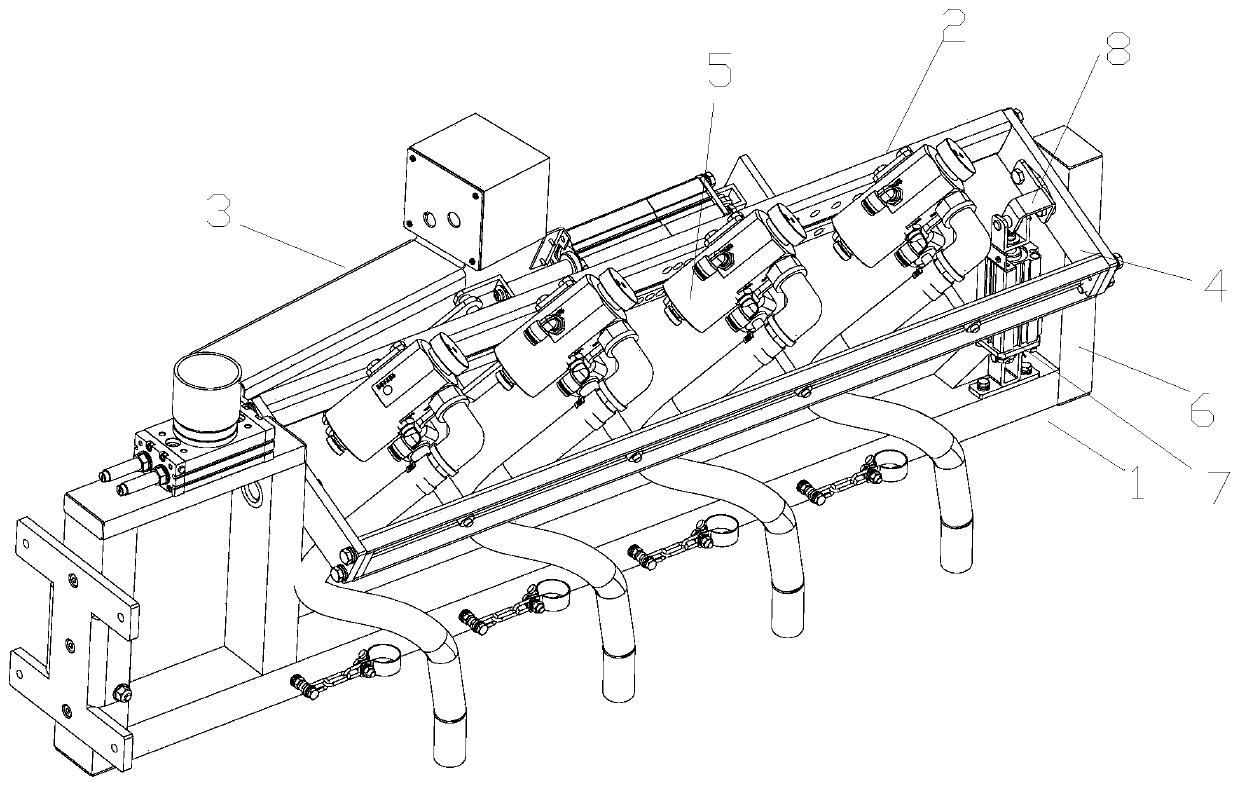

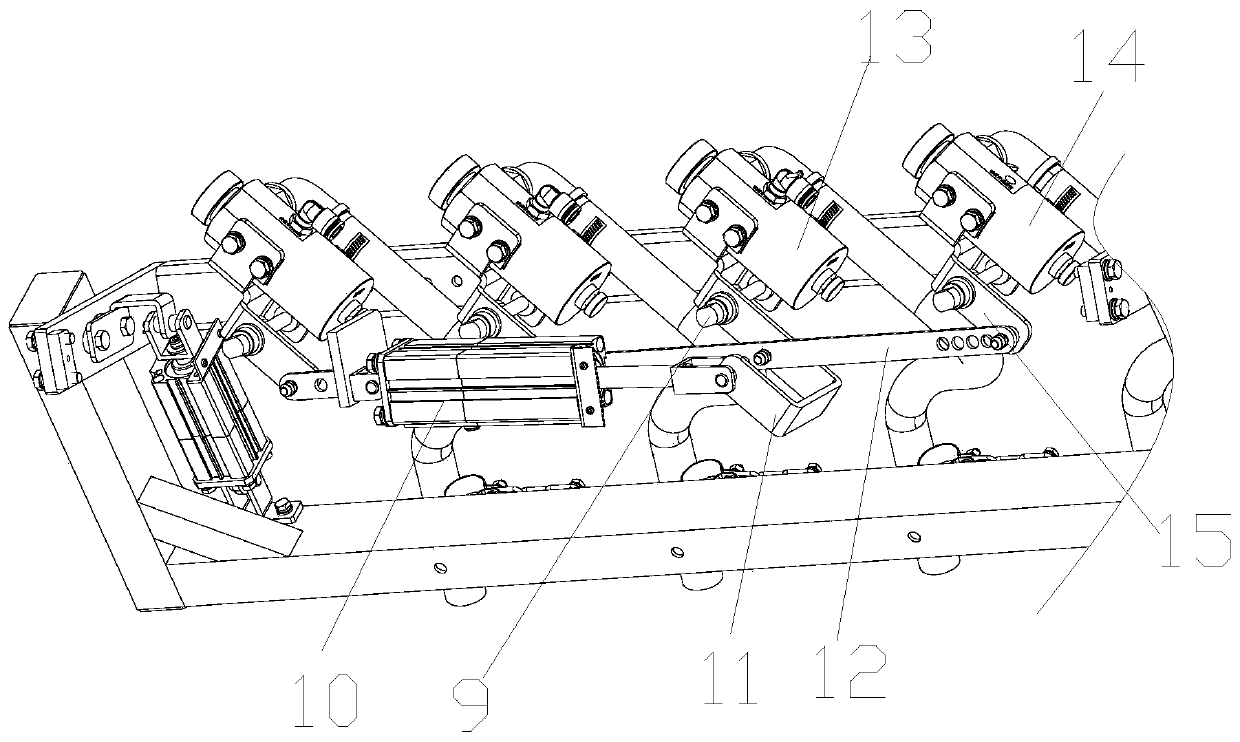

[0019] see Figure 1-2 , the present invention provides a technical solution:

[0020] An angle-adjustable automatic painting equipment, including a fixed bracket assembly 1, an automatic spray gun rotation mechanism assembly 2, and a rotation sensor bracket assembly 3, the automatic spray gun rotation mechanism includes a rotating frame 4, and the rotating frame is connected to the fixed bracket assembly, and can rotate clockwise or counterclockwise with the horizontal central axis of the fixed bracket assembly as the rotating shaft, adjust the angle formed between the spray gun and the wall surface to be sprayed in the longitudinal direction, and also include several spray guns 5, and several of the spray guns are connected to On the rotating frame body, the longitudinal axis of the rotating frame body can be rotated clockwise or counterclockwise to adjust the angle formed by the spray gun and the wall surface to be sprayed in the transverse direction, wherein the plane wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com