Lanthanum zirconic acid/yttrium titanate film material and method for making same

A thin film material, the technology of lanthanum zirconate, which is applied in the field of lanthanum zirconate/yttrium titanate thin film material and its preparation, can solve the problem of not having the excellent performance of lanthanum zirconate/yttrium titanate thin film material, difficulty in reducing manufacturing cost, and complicated process and other problems, to achieve the effect of easy operation and control, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

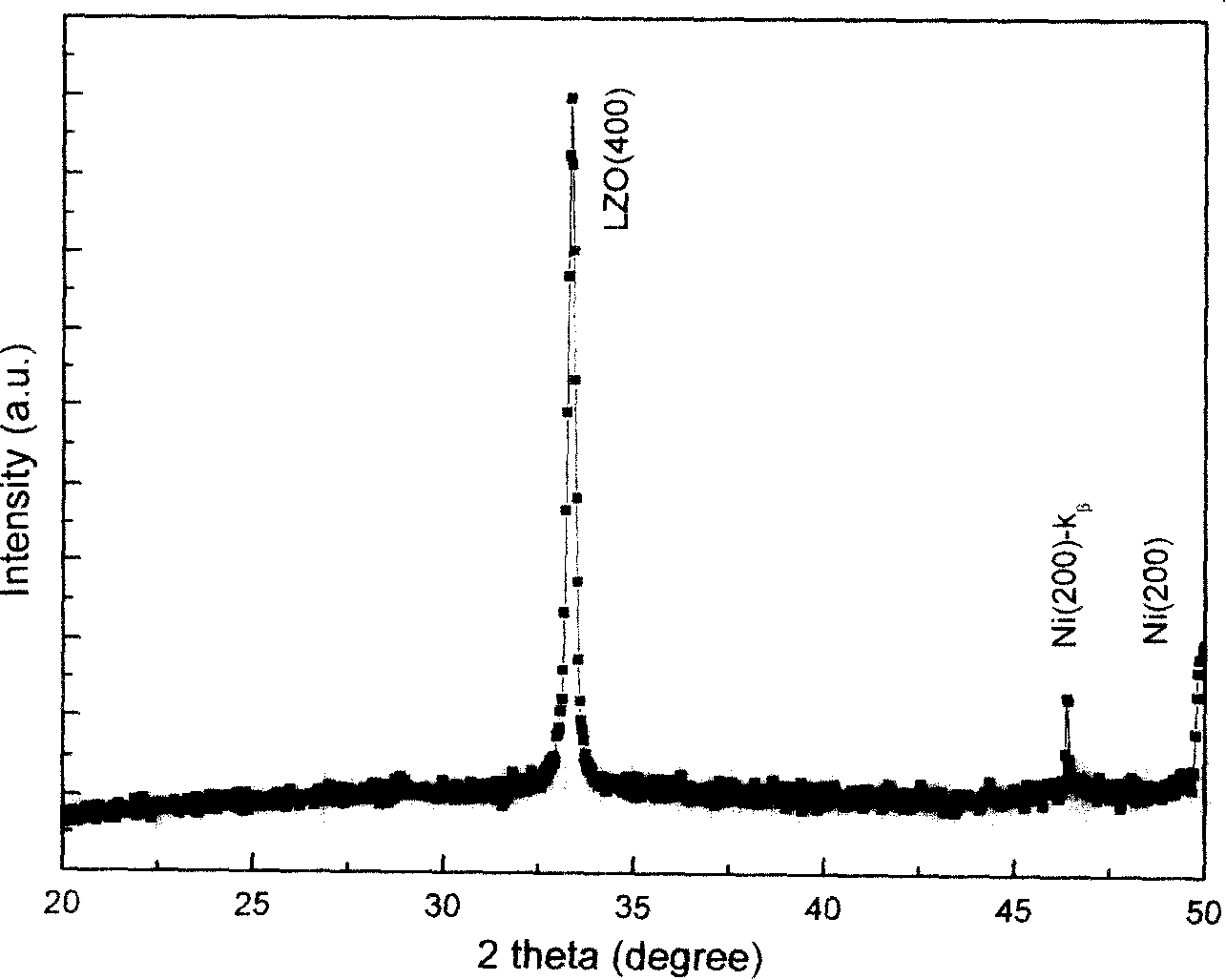

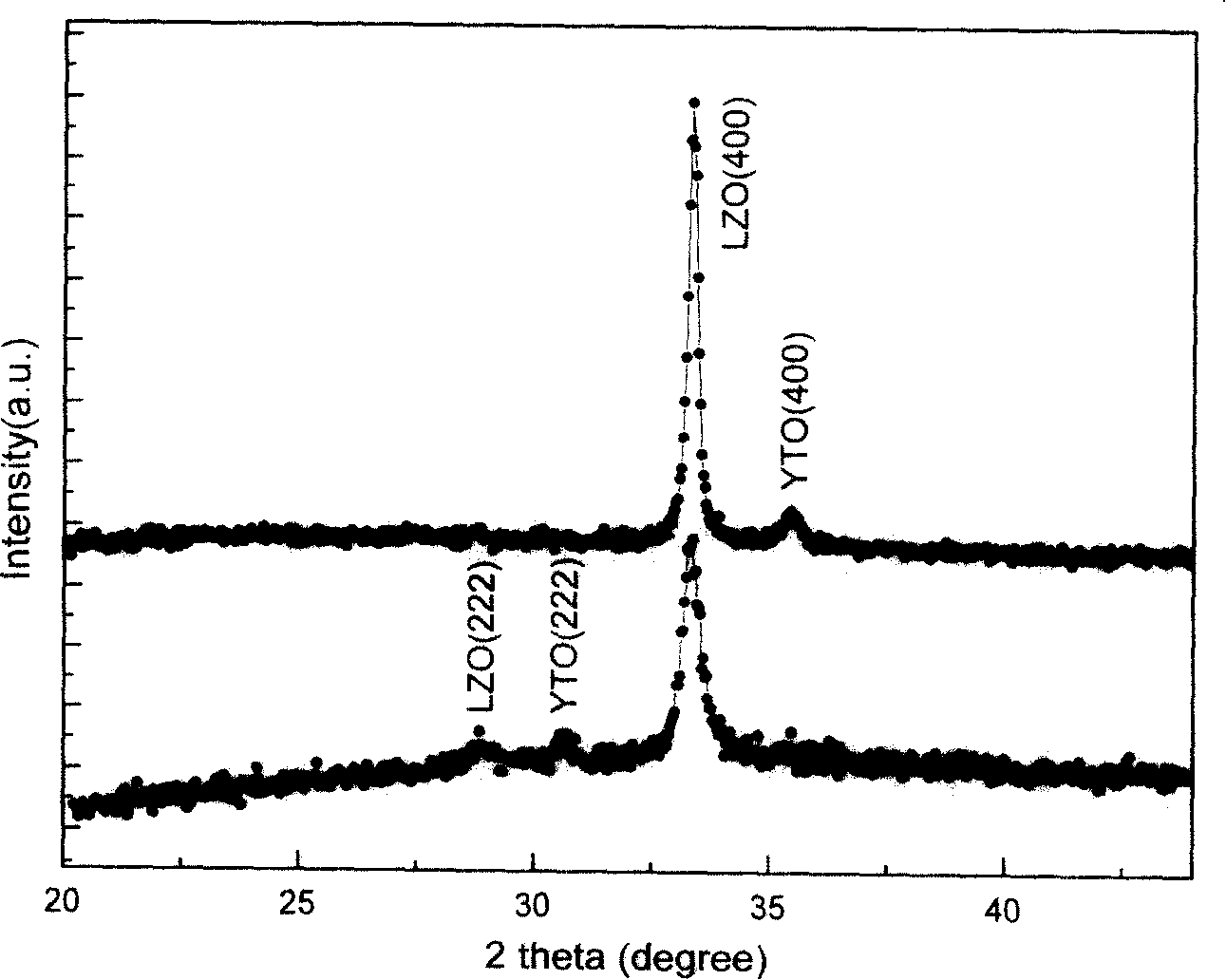

[0018]Embodiment 1: complete preparation successively according to the following steps: a) according to lanthanum: zirconium is the molar ratio of 1: 1, respectively weigh two parts of lanthanum acetate, zirconium n-propoxide, first two parts of lanthanum acetate are dissolved in two parts respectively In the propionic acid solution, stir at 50° C. for 20 minutes until the lanthanum acetate is completely dissolved, wherein the volume of propionic acid: the molar number of lanthanum acetate is 10 liters: 1 mole and 2.5 liters: 1 mole respectively. Then two parts of zirconium n-propoxide were respectively added to the propionic acid solution with different volume ratio and molar number and stirred until completely dissolved to obtain the precursor colloid of the lanthanum zirconate seed layer and the precursor colloid of the lanthanum zirconate subsequent layer respectively. b) Coating the precursor colloid of the lanthanum zirconate seed layer onto the (100) axis-oriented metal ...

Embodiment 2

[0019] Embodiment 2: complete preparation successively according to the following steps: a) According to the mol ratio of lanthanum: zirconium is 1: 1, weigh two parts of lanthanum acetate and zirconium n-propoxide respectively, first two parts of lanthanum acetate are dissolved in two parts respectively In the propionic acid solution, stir at 60° C. for 17 minutes until the lanthanum acetate is completely dissolved, wherein the volume of propionic acid: the molar number of lanthanum acetate is 13 liters: 1 mole and 3 liters: 1 mole respectively. Then two parts of zirconium n-propoxide were respectively added to the propionic acid solution with different volume ratio and molar number and stirred until completely dissolved to obtain the precursor colloid of the lanthanum zirconate seed layer and the precursor colloid of the lanthanum zirconate subsequent layer respectively. b) Coating the precursor colloid of the lanthanum zirconate seed layer onto the (100) axis-oriented metall...

Embodiment 3

[0020] Embodiment 3: complete preparation successively according to the following steps: a) according to the mol ratio of lanthanum: zirconium is 1: 1, respectively weigh two parts of lanthanum acetate, zirconium n-propoxide, first two parts of lanthanum acetate are dissolved in two parts respectively In the propionic acid solution, stir at 70° C. for 15 minutes until the lanthanum acetate is completely dissolved, wherein the volume of propionic acid: the molar number of lanthanum acetate is 15 liters: 1 mole and 3.8 liters: 1 mole respectively. Then two parts of zirconium n-propoxide were respectively added to the propionic acid solution with different volume ratio and molar number and stirred until completely dissolved to obtain the precursor colloid of the lanthanum zirconate seed layer and the precursor colloid of the lanthanum zirconate subsequent layer respectively. b) Coating the precursor colloid of the lanthanum zirconate seed layer onto the (100) axis-oriented metal n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com