Aluminum alloy and preparation method and application thereof

A technology of aluminum alloy and total amount, which is applied in the field of aluminum alloy and its preparation, can solve the problems of not meeting the heat dissipation requirements of electronic products and low thermal conductivity, and achieve the effects of good comprehensive mechanical properties, high elongation, and good casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

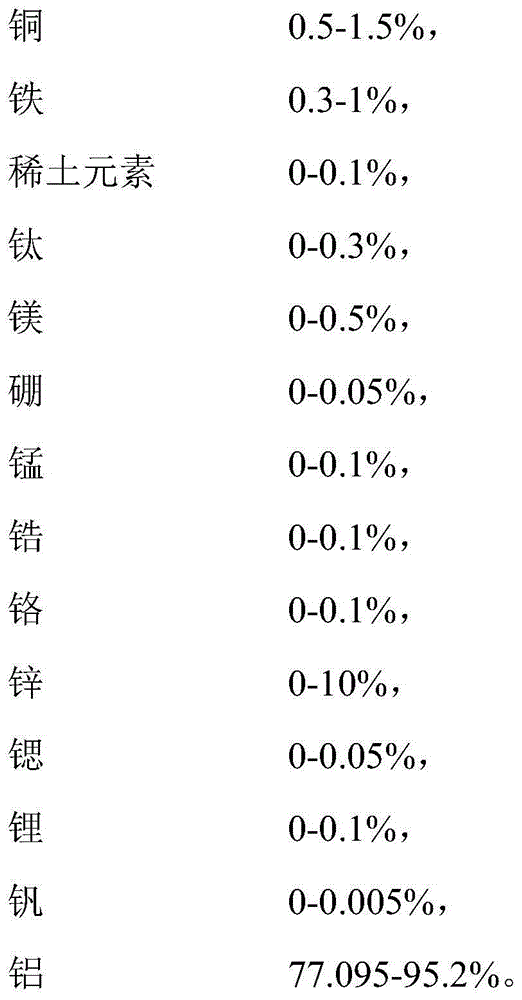

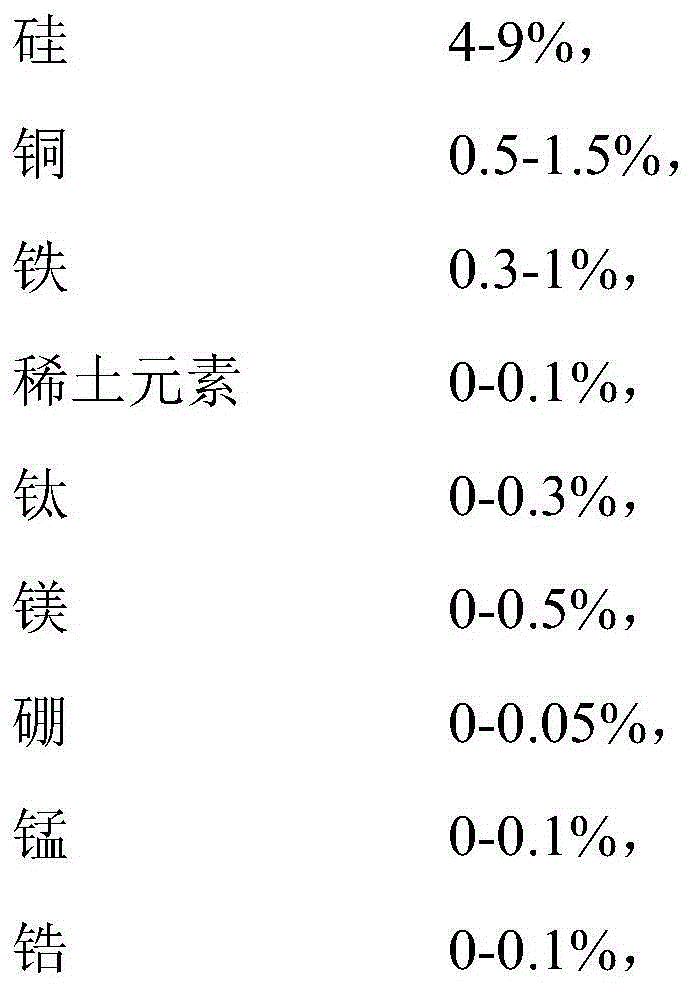

Method used

Image

Examples

Embodiment 1

[0049] Aluminum alloy raw materials were prepared according to the composition in Table 1. The aluminum alloy raw material is smelted and cast into an ingot, and the obtained ingot is mold-cast on a 160T cold die-casting machine, so as to obtain the die-cast body of the aluminum alloy of the present invention. Among them, the melting temperature is 750°C, the injection speed is 2m / s, the mold temperature is 200°C, and the casting size is 200mm×30mm×3mm.

[0050] The surface hardness, thermal conductivity, yield strength and elongation of the prepared aluminum alloy were measured, and the results are listed in Table 2.

Embodiment 2-15

[0052] The aluminum alloy die-cast body was prepared by the same method as in Example 1, except that the aluminum alloy raw material was prepared according to the composition in Table 1.

[0053] The surface hardness, thermal conductivity, yield strength and elongation of the prepared aluminum alloy were measured, and the results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com