Ternary composite with core-shell structure and preparation method therefor

A composite material, core-shell structure technology, applied in structural parts, electrical components, electrochemical generators, etc., can solve problems such as poor rate performance and poor safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

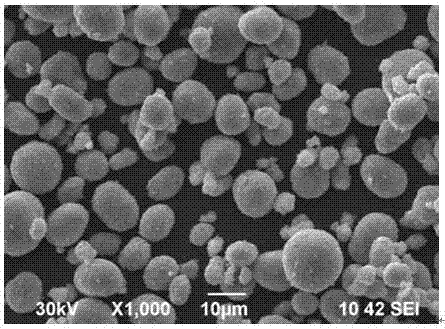

Image

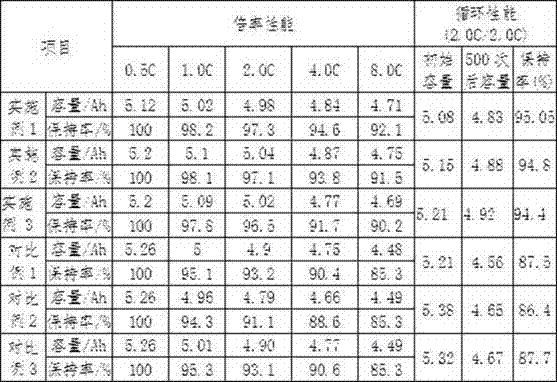

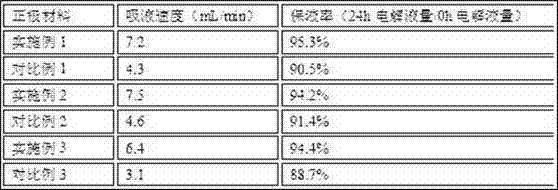

Examples

Embodiment 1

[0017] 1) Weigh 10g of lithium zirconate, 0.4g of polyvinylidene fluoride, and 3g of activated carbon and add it to 1500mL of N-methylpyrrolidone, and then disperse at a high speed to obtain a lithium zirconate / activated carbon composite solution (referred to as solution A);

[0018] 2) Then weigh 150gLiNi 0.6 co 0.2 mn 0.2 o 2 Add the ternary material to solution A, stir evenly, filter, wash, and vacuum dry at 80°C to obtain the ternary material / lithium zirconate composite material B;

[0019] 3) After that, 25 grams of polypropylene carbonate material was dissolved in 250 grams of ethyl methyl carbonate (EMC) to form a polymer solution. After stirring at a low speed for 30 minutes, a polymer solution was obtained, and then 30 grams of composite material B was weighed and added to After being uniformly stirred in the polymer solution, it is dried and pulverized to obtain a ternary composite material whose outer layer is coated with a polymer.

Embodiment 2

[0021] 1) Weigh 10g of lithium zirconate, 0.2g of polyvinylidene fluoride, and 2g of activated carbon into 1000mL of N-methylpyrrolidone, and then disperse at high speed to obtain a lithium zirconate / activated carbon composite solution (referred to as solution A);

[0022] 2) Then weigh 100gLiNi 0 . 8 co 0.1 mn 0.1 o 2 Add the ternary material to solution A, stir evenly, filter, wash, and vacuum dry at 80°C to obtain the ternary material / lithium zirconate composite material B;

[0023] 3) Dissolve 20 grams of polymethylsiloxane material in 200 grams of ethyl methyl carbonate (EMC) to form a polymer solution, stir at a low speed for 10 minutes to obtain a polymer solution, and then weigh 10 grams of composite material B to add into the polymer solution, stirred evenly, dried and pulverized to obtain a ternary composite material coated with a polymer on the outer layer.

Embodiment 3

[0025] 1) Weigh 10g of lithium zirconate, 0.5g of polyvinylidene fluoride, and 4g of activated carbon into 2000mL of N-methylpyrrolidone, and then disperse at high speed to obtain a lithium zirconate / activated carbon composite solution (referred to as solution A);

[0026] 2) Then weigh 200gLiNi 0.5 co 0.2 al 0.3 o 2 Add the ternary material to solution A, stir evenly, filter, wash, and vacuum dry at 80°C to obtain the ternary material / lithium zirconate composite material B;

[0027] 3) After that, dissolve 30 grams of polymethyl acrylate material in 300 grams of ethyl methyl carbonate (EMC) to form a polymer solution. After stirring at a low speed for 60 minutes, a polymer solution is obtained, and then weigh 50 grams of composite material B and add it to the polymerization After being stirred uniformly, it is dried and pulverized to obtain a ternary composite material whose outer layer is coated with a polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com