Preparation technique of composite lithium zirconate and modified biphase lithium titanate/titanium dioxide anode material

A technology of composite lithium zirconate and double-phase lithium titanate, which is applied in battery electrodes, structural parts, electrical components, etc., to achieve the effects of strong practicability, simple preparation method, and good electronic and ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the preparation of lithium titanate in the present invention, lithium hydroxide and tetrabutyl titanate are uniformly used as lithium source and titanium source. Weigh about 2.9g of lithium hydroxide with a balance, add an appropriate amount of deionized water to dissolve; weigh 26.0mL (25.6g) of tetrabutyl titanate with a graduated cylinder and dissolve it in 20mL of absolute ethanol, and dissolve the tetrabutyl titanate solution in Add to lithium hydroxide solution with stirring. After mixing evenly, dry at 120°C, and heat the dried product to about 700°C for 5 hours. Turn off the heating furnace, cool down to room temperature naturally, and obtain about 6 g of white powder, which is lithium titanate (LTO).

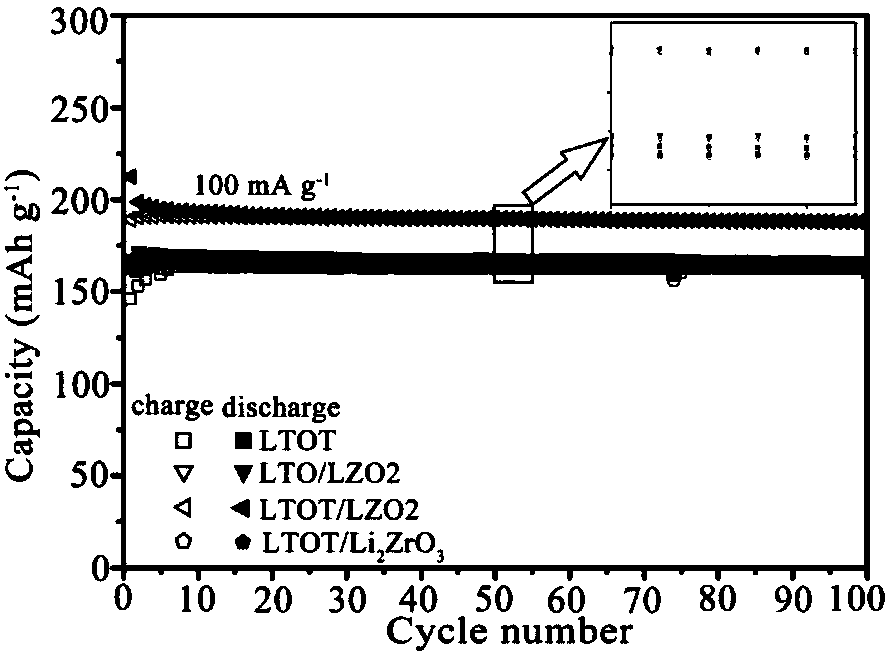

[0040] The lithium titanate is mixed with the zirconium source and the lithium source for preparing the composite lithium zirconate to prepare the composite lithium zirconate modified lithium titanate negative electrode material. Weigh 1.5g of lithium titana...

Embodiment 2

[0042] Weigh about 2.6g of lithium hydroxide with a balance, add an appropriate amount of deionized water to dissolve; weigh 26.0mL (25.6g) of tetrabutyl titanate with a graduated cylinder and dissolve it in 20mL of absolute ethanol, and dissolve the tetrabutyl titanate solution in Add to lithium hydroxide solution with stirring. After mixing evenly, dry at 120°C, and heat the dried product to about 700°C for 5 hours. Turn off the heating furnace, cool down to room temperature naturally, and obtain about 6 g of white powder, which is duplex lithium titanate / titanium dioxide.

[0043] The biphasic lithium titanate / titanium dioxide and lithium zirconate (Li 2 ZrO 3 ) zirconium source and lithium source are mixed to prepare lithium zirconate modified dual-phase lithium titanate / titanium dioxide negative electrode material. Weigh 1.5g of biphasic lithium titanate / titanium dioxide, 0.0345g of zirconium nitrate, 0.0121g of lithium nitrate in 20mL of deionized water and stir evenl...

Embodiment 3

[0045] Weigh 1.5g of biphasic lithium titanate / titanium dioxide, 0.0345g of zirconium nitrate, 0.0241g of lithium nitrate in 20mL of deionized water and stir evenly. A composite lithium zirconate modified dual-phase lithium titanate / titanium dioxide anode material with a mass ratio of 0.01:1.5 to the dual-phase lithium titanate / titanium dioxide. This sample was named LTOT / LZO1.

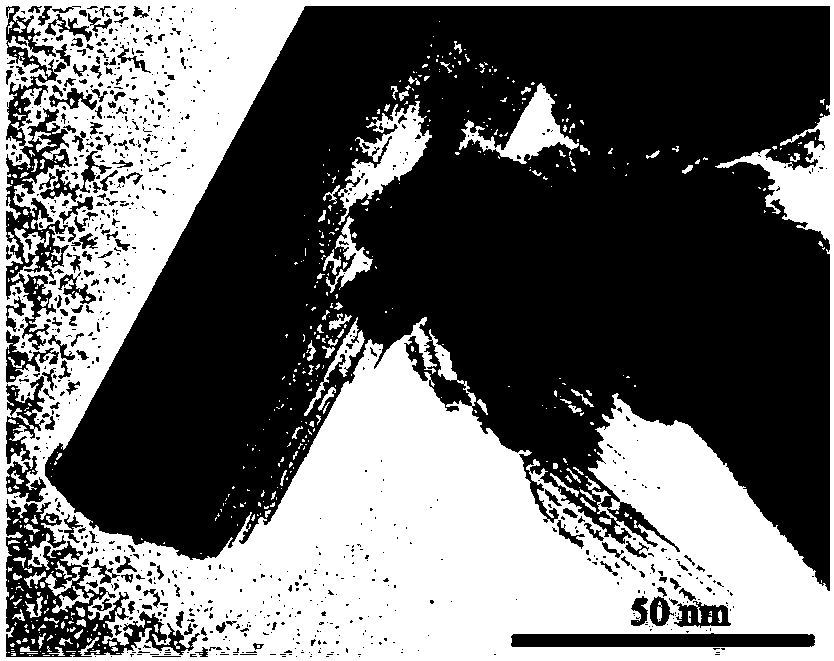

[0046] The transmission electron microscope morphology of the composite lithium zirconate modified dual-phase lithium titanate / titanium dioxide negative electrode material obtained in this example is as follows: figure 1 As shown, it can be seen that the dual-phase lithium titanate / titanium dioxide is composed of nanocrystals with a size of about 10-50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com