High temperature-resistant lithium ion battery composite diaphragm and preparation method thereof

A lithium-ion battery, composite diaphragm technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as high cost and complex process, and achieve the effects of low cost, strong heat resistance, and high oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

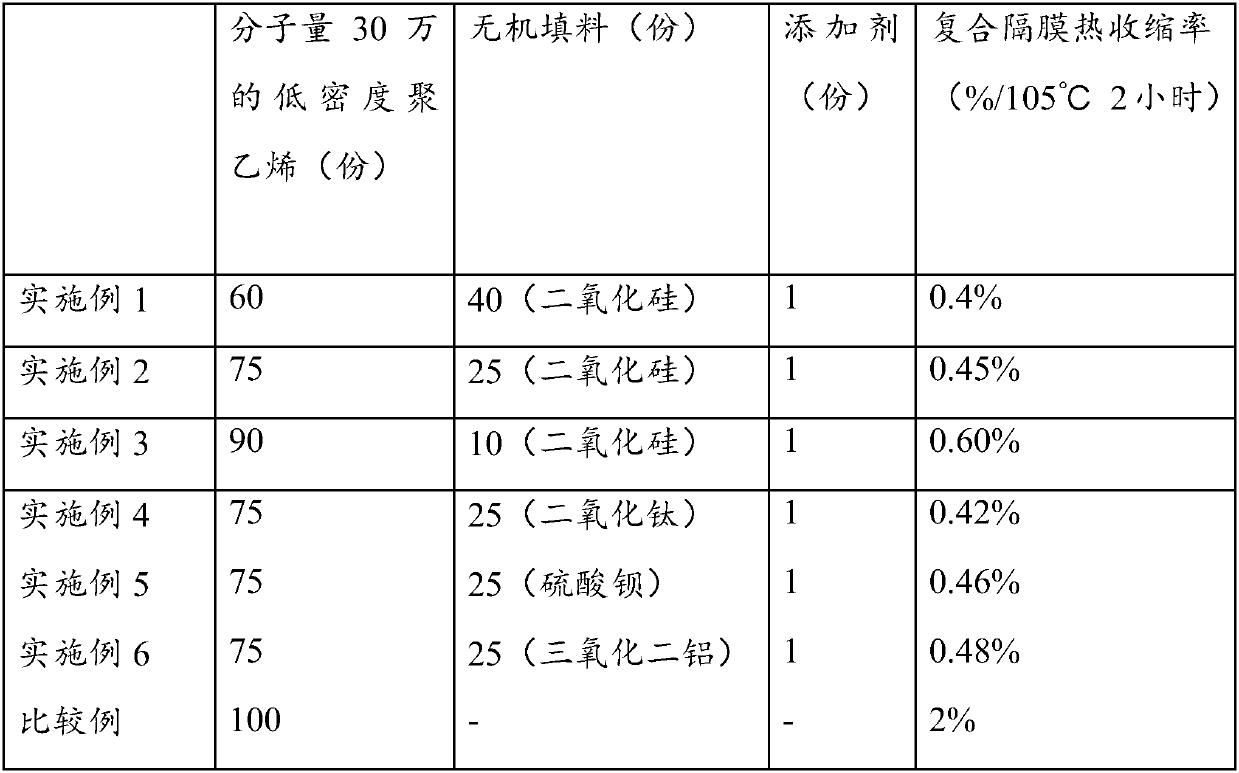

Embodiment 1

[0034] a. Material preparation step: use a density of 0.94-0.96g / cm 3 High-density polyethylene with a molecular weight between 450,000 and 450,000 is used as the high-density polyethylene raw material for the surface layer. The density is 0.91-0.93g / cm 3 Low-density polyethylene with a molecular weight of 300,000 is used as the low-density polyethylene raw material of the core layer, and silicon dioxide is used as the inorganic filler of the core layer. The low-density polyethylene is mixed with silicon dioxide and additives (leveling agent, Plasticizer, smooth agent) are mixed as the raw material of core layer, and wherein in the mixture of this low-density polyethylene and inorganic filler and additive, the ratio of low-density polyethylene and inorganic filler and additive is 60 parts by weight: 40 parts by weight: 1 part by weight.

[0035]b. Three-layer extrusion step: Use a single-screw extruder with an aspect ratio L / D≥34 to melt and extrude the high-density polyethy...

Embodiment 2

[0042] Using the same materials and process steps as in Example 1, but in the mixture of low-density polyethylene and inorganic filler and additive in step a, the ratio of low-density polyethylene to inorganic filler and additive is 75 parts by weight: 25 parts by weight: 1 part by weight to prepare a lithium-ion battery composite diaphragm. The thermal shrinkage rate of the obtained composite separator was 0.45% at 105° C. for 2 hours according to heat resistance measurement.

Embodiment 3

[0044] Using the same material and process steps as in Example 1, but in the mixture of low-density polyethylene and inorganic filler and additive in step a, the ratio of low-density polyethylene to inorganic filler and additive is 90 parts by weight: 10 parts by weight: 1 part by weight to prepare a lithium-ion battery composite diaphragm. The thermal shrinkage rate of the obtained composite separator was 0.60% at 105° C. for 2 hours according to heat resistance measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com