Nano electrode material of energy storage lithium ion battery

A lithium-ion battery and nano-electrode technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as low conductivity and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

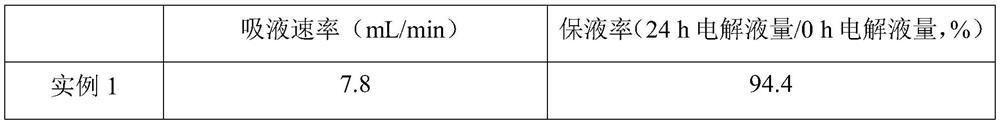

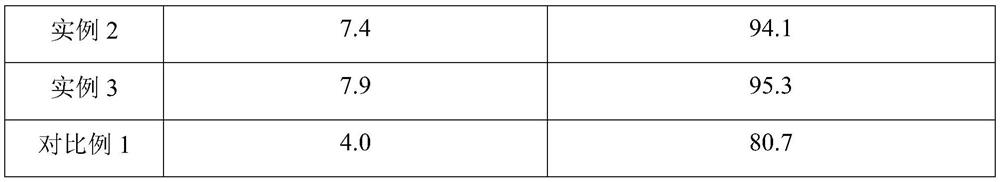

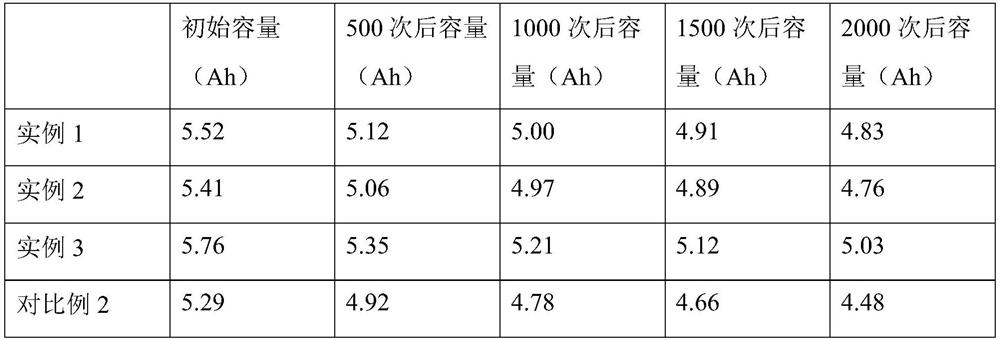

Examples

example 1

[0024] The nanometer electrode material for energy storage lithium ion battery is prepared by the following method:

[0025] Step 1) dissolving lithium carbonate in an aqueous solution of polyethylene glycol as a lithium source, stirring to form a solution, wherein the concentration of the lithium source is 0.5mol / L;

[0026] Step 2) Dissolving tetrabutyl titanate as a titanium source in an aqueous solution of polyethylene glycol and stirring to form a solution, wherein the concentration of the lithium source is 0.6 mol / L;

[0027] Step 3) adding carbon nanotubes to a mixed solution of acetic acid and nitric acid, in the mixed solution of acetic acid and nitric acid, the concentration of nitric acid is 60wt.%, adjust the pH to 4, so that the concentration of carbon nanotubes is 10mg / mL, ultrasonic treatment for 2h , forming a suspension;

[0028] Step 4) Mix the solutions obtained in steps 1) and 2) in equal volumes, and continuously add the suspension obtained in step 3) dur...

example 2

[0033] The nanometer electrode material for energy storage lithium ion battery is prepared by the following method:

[0034] Step 1) dissolving lithium carbonate in an aqueous solution of polyethylene glycol as a lithium source, stirring to form a solution, wherein the concentration of the lithium source is 0.5mol / L;

[0035] Step 2) Dissolving tetrabutyl titanate as a titanium source in an aqueous solution of polyethylene glycol and stirring to form a solution, wherein the concentration of the lithium source is 0.6 mol / L;

[0036] Step 3) adding carbon nanotubes to a mixed solution of acetic acid and nitric acid, in the mixed solution of acetic acid and nitric acid, the concentration of nitric acid is 70wt.%, adjust the pH to 4.5, so that the concentration of carbon nanotubes is 10mg / mL, ultrasonic treatment for 2h , forming a suspension;

[0037] Step 4) Mix the solutions obtained in steps 1) and 2) in equal volumes, and continuously add the suspension obtained in step 3) d...

example 3

[0042] The nanometer electrode material for energy storage lithium ion battery is prepared by the following method:

[0043] Step 1) dissolving lithium carbonate in an aqueous solution of polyethylene glycol as a lithium source, stirring to form a solution, wherein the concentration of the lithium source is 0.5mol / L;

[0044] Step 2) Dissolving tetrabutyl titanate as a titanium source in an aqueous solution of polyethylene glycol and stirring to form a solution, wherein the concentration of the lithium source is 0.6 mol / L;

[0045] Step 3) adding carbon nanotubes to a mixed solution of acetic acid and nitric acid, in the mixed solution of acetic acid and nitric acid, the concentration of nitric acid is 65wt.%, adjust the pH to 4.5, so that the concentration of carbon nanotubes is 10mg / mL, ultrasonic treatment for 2h , forming a suspension;

[0046] Step 4) Mix the solutions obtained in steps 1) and 2) in equal volumes, and continuously add the suspension obtained in step 3) d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com