A kind of lithium ion battery silicon carbon negative electrode material and preparation method thereof

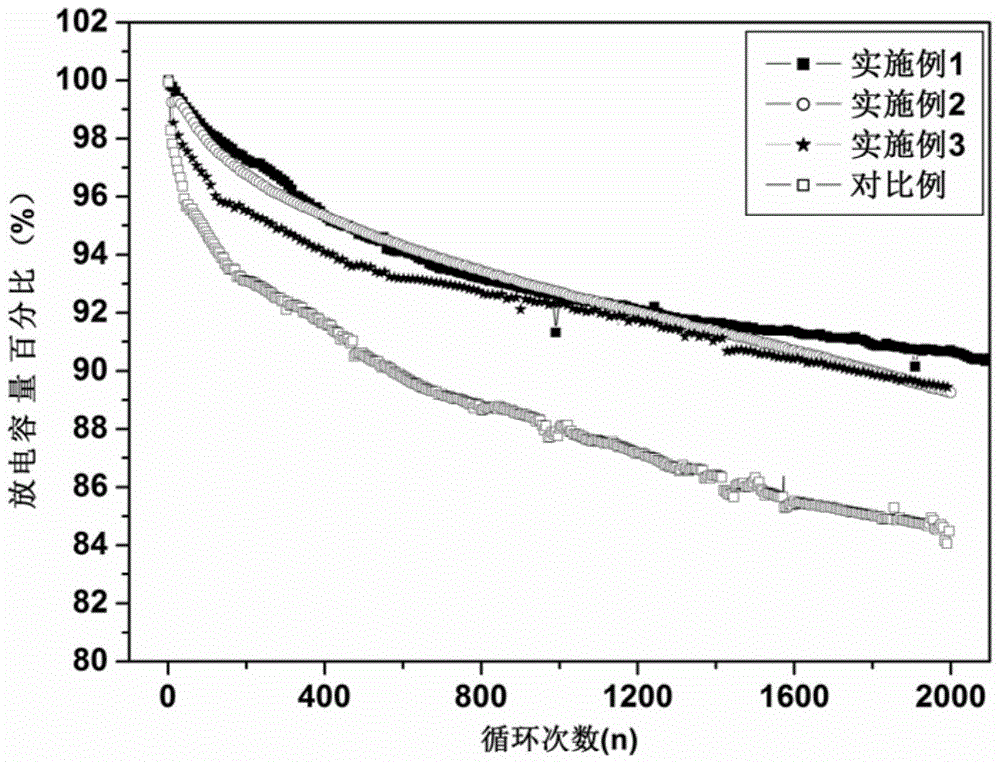

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., and can solve the problems of high expansion rate, poor cycle performance, and low gram capacity of negative electrode materials, etc. Achieve the effect of low expansion rate, slow decay speed and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

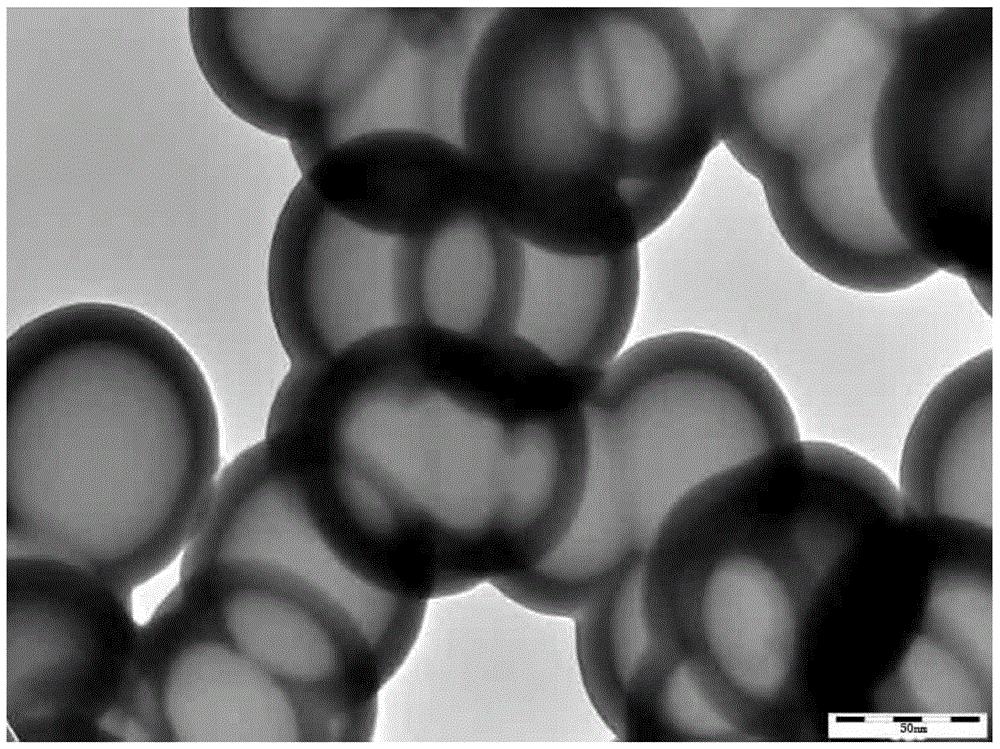

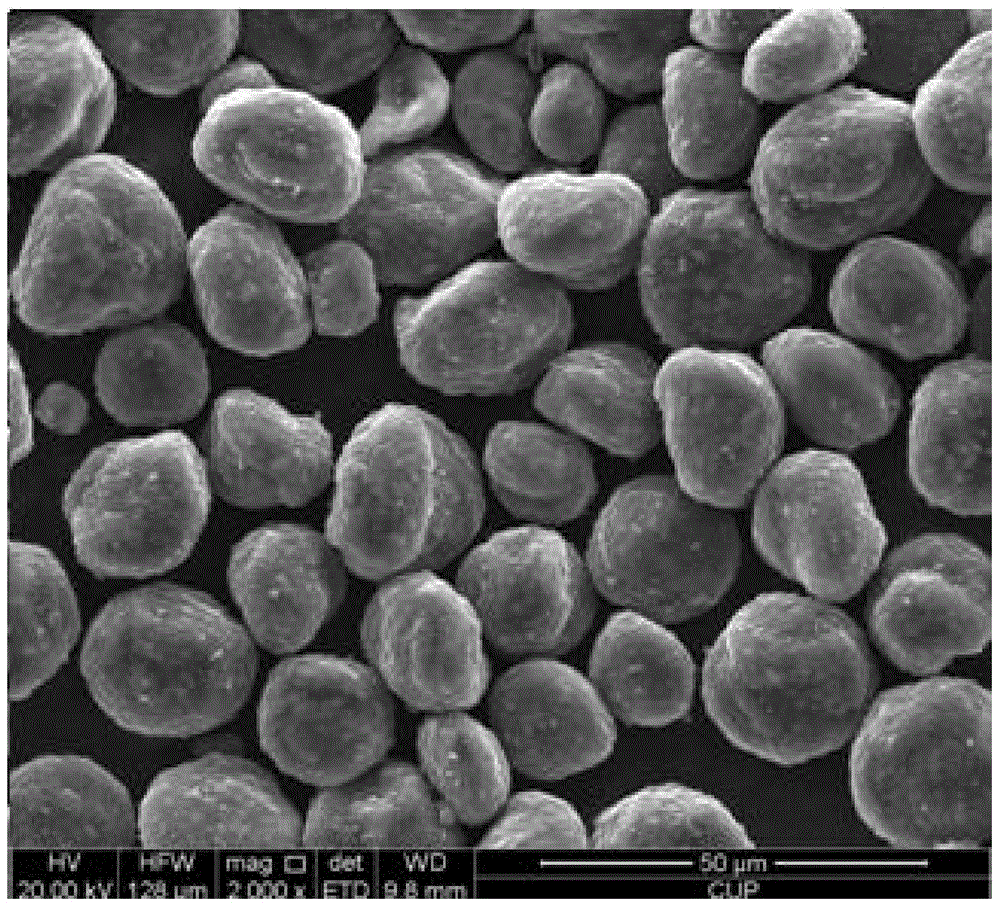

[0050] The lithium-ion battery silicon carbon negative electrode material of the present embodiment comprises a core-shell structure, and an intermediate layer is also arranged between the core and the shell; the core contains silicon monoxide, the intermediate layer is a buffer layer of hollow carbon spheres, and the shell is coated with graphite Floor.

[0051] The silicon carbon negative electrode material is granular; its particle size is 15-25 μm. The ratio of the diameter of the core to the thickness of the middle layer and the thickness of the shell is 100:50-100:200-500.

[0052] The preparation method of the lithium ion battery silicon carbon negative electrode material of the present embodiment comprises the following steps:

[0053] 1) Preparation of silicon precursor: Take 500g of toluene and put it into the reaction kettle, then add 10g of silicon monoxide (silicon material), 20g of sodium lauryl sulfate (dispersant), 1.0g of trimethylmethoxysilane (coupling age...

Embodiment 2

[0058] The lithium-ion battery silicon-carbon negative electrode material of the present embodiment comprises a core-shell structure, and an intermediate layer is also arranged between the core and the shell; the core is silicon monoxide, the intermediate layer is a buffer layer of hollow carbon spheres, and the shell is coated with graphite Floor.

[0059] The silicon carbon negative electrode material is granular; its particle size is 15-25 μm. The ratio of the diameter of the core to the thickness of the middle layer and the thickness of the shell is 100:50-100:200-500.

[0060] The preparation method of the lithium ion battery silicon carbon negative electrode material of the present embodiment comprises the following steps:

[0061] 1) Preparation of silicon precursor: Take 1000g of toluene into the reaction kettle, then add 10g of silicon monoxide (silicon material), 10g of sodium lauryl sulfate (dispersant), 5g of tributylmethoxysilane (coupling agent), 1g of divinylb...

Embodiment 3

[0066] The lithium-ion battery silicon-carbon negative electrode material of the present embodiment comprises a core-shell structure, and an intermediate layer is also arranged between the core and the shell; the core is silicon monoxide, the intermediate layer is a buffer layer of hollow carbon spheres, and the shell is coated with graphite Floor.

[0067] The silicon carbon negative electrode material is granular; its particle size is 15-25 μm. The ratio of the diameter of the core to the thickness of the middle layer and the thickness of the shell is 100:50-100:200-500.

[0068] The preparation method of the lithium ion battery silicon carbon negative electrode material of the present embodiment comprises the following steps:

[0069] 1) Preparation of silicon precursor: Take 100g of chloroform and add it to the reaction kettle, then add 10g of silicon monoxide (silicon material), 30g of hexadecyltrimethylammonium bromide (dispersant), 0.5g of trimethylchlorosilane ( Coup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com