Integrated lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode technology, applied in the field of integrated lithium-ion batteries based on Janus diaphragm and its preparation, can solve problems such as structural failure, interface relaxation, damage, etc., achieve small roughness, large roughness, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

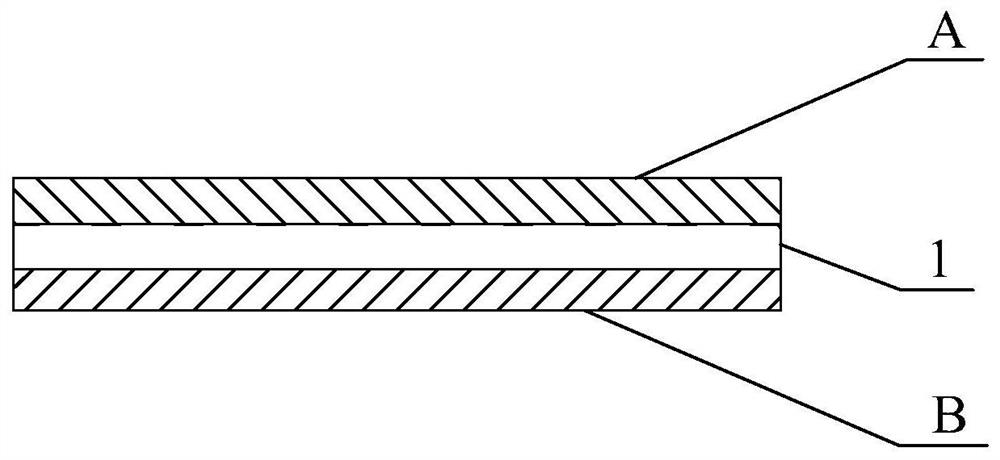

[0036] Such as figure 1 As shown, the Janus diaphragm is composed of polyimide high-temperature resistant support layer 1 and polyacrylic acid polar functional layer A and polytetrafluoroethylene-hexafluoropropylene non-polar functional layer B loaded on both sides of the high-temperature resistant support layer; the The thickness of the Janus separator is 18 μm, the porosity is 45.7%, the heat shrinkage rate is 0.0% (150°C, 2h), the surface energy of the polar functional layer is 45.8mN / m, and the surface energy of the non-polar functional layer is 16.3mN / m;

[0037] (1) Activate the A side of the Janus diaphragm at 55°C in ozone;

[0038] (2) Activate the B side of the Janus diaphragm at 35°C in N,N-dimethylformamide;

[0039] (3) Heat the Janus diaphragm and the positive and negative electrode sheets after steps (1) and (2) according to [negative electrode sheet / A-B / positive electrode sheet / B-A] or [B-A / negative electrode sheet / A-B / positive electrode sheet] The structural...

Embodiment 2

[0042] Such as figure 1 As shown, the Janus diaphragm is composed of titanium oxide high-temperature resistant support layer 1 and polyethylene oxide polar functional layer A and polytetrafluoroethylene non-polar functional layer B loaded on both sides of the high-temperature resistant support layer; the Janus diaphragm thickness 5μm, porosity 25%, thermal shrinkage rate 0.5% (150°C, 2h), surface energy of polar functional layer is 60.5mN / m, surface energy of non-polar functional layer is 15.8mN / m;

[0043] (1) Activate the A side of the Janus diaphragm at 45°C in nitric acid containing 5wt% ammonia;

[0044] (2) Activate the B side of the Janus diaphragm at 10°C in ethanol;

[0045] (3) Heat the Janus diaphragm and the positive and negative electrode sheets after steps (1) and (2) according to [negative electrode sheet / A-B / positive electrode sheet / B-A] or [B-A / negative electrode sheet / A-B / positive electrode sheet] The structural unit is obtained by pressing and combining. D...

Embodiment 3

[0048] Such as figure 1 As shown, the Janus diaphragm is composed of polyether ether ketone high temperature resistant support layer 1 and polypropylene oxide polar functional layer A and graphene nonpolar functional layer B loaded on both sides of the high temperature resistant support layer; the thickness of the Janus diaphragm is 50 μm, porosity 65%, thermal shrinkage rate 0.2% (150°C, 2h), the surface energy of the polar functional layer is 55.6mN / m, and the surface energy of the non-polar functional layer is 13.8mN / m;

[0049] (1) Activate the A side of the Janus diaphragm at 85°C in sodium perchlorate;

[0050] (2) Activate the B side of the Janus diaphragm at 45°C in N-methylpyrrolidone;

[0051] (3) Heat the Janus diaphragm and the positive and negative electrode sheets after steps (1) and (2) according to [negative electrode sheet / A-B / positive electrode sheet / B-A] or [B-A / negative electrode sheet / A-B / positive electrode sheet] The structural unit was obtained by pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com