A kind of lithium-ion battery silicon composite negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of high gram capacity, good cycle performance, low expansion rate, etc., and achieve high capacity and cycle performance. Good, low expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

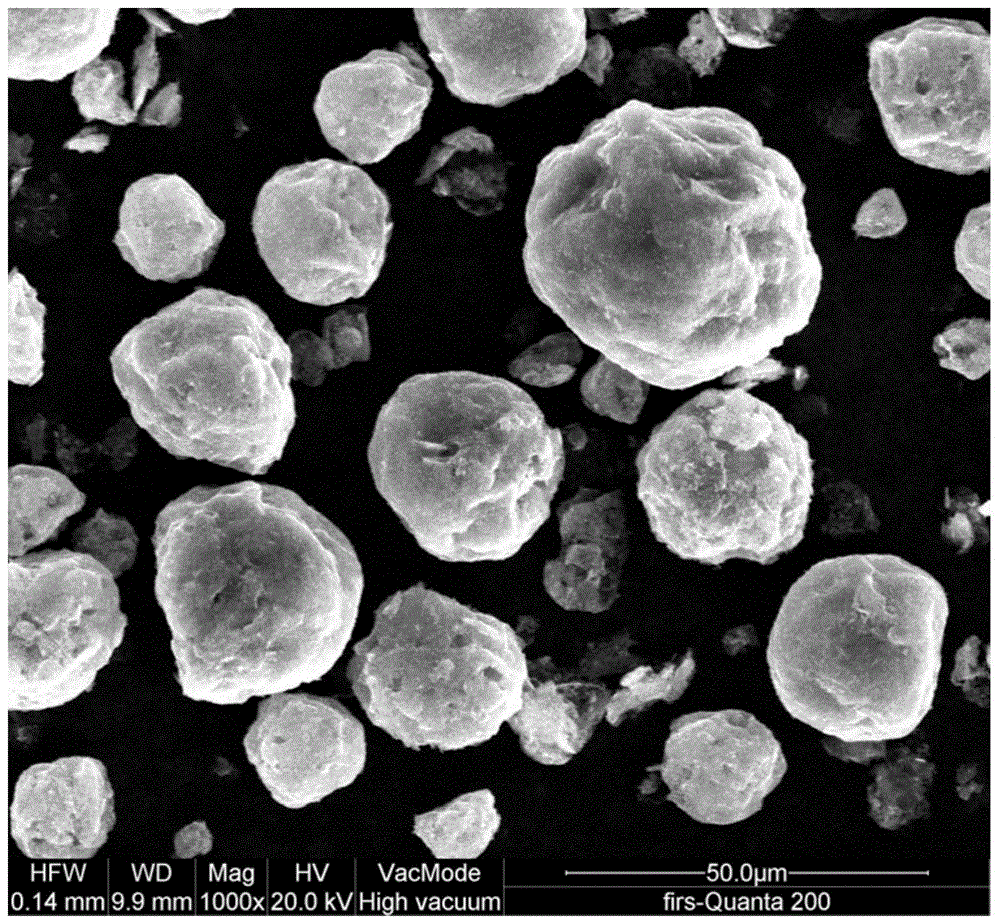

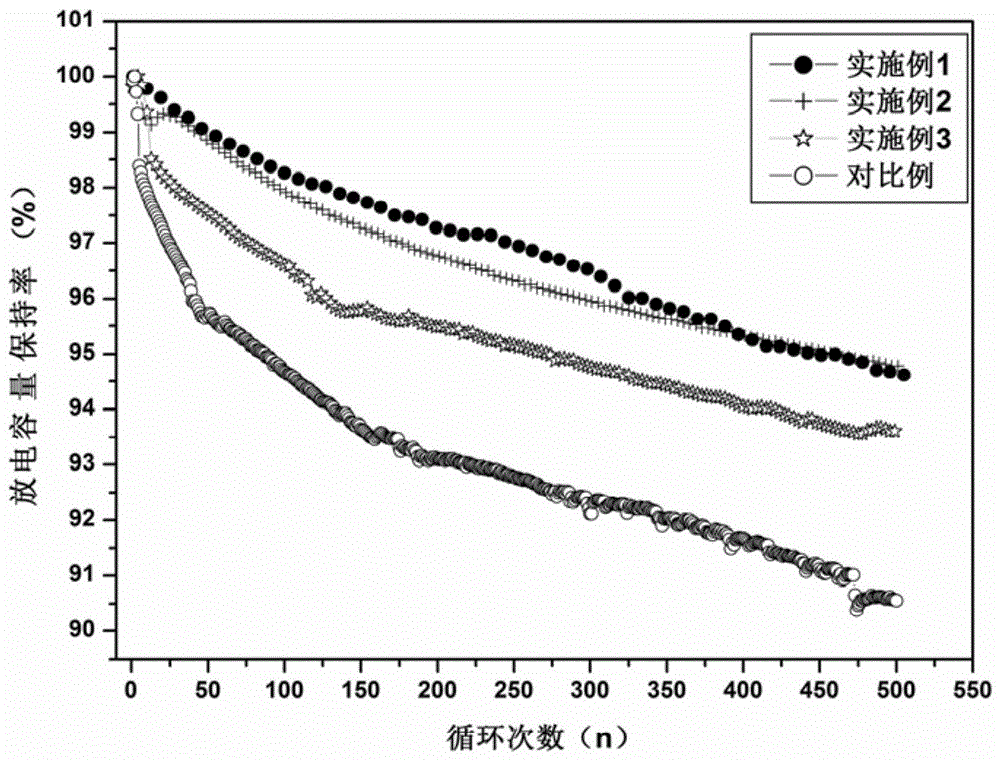

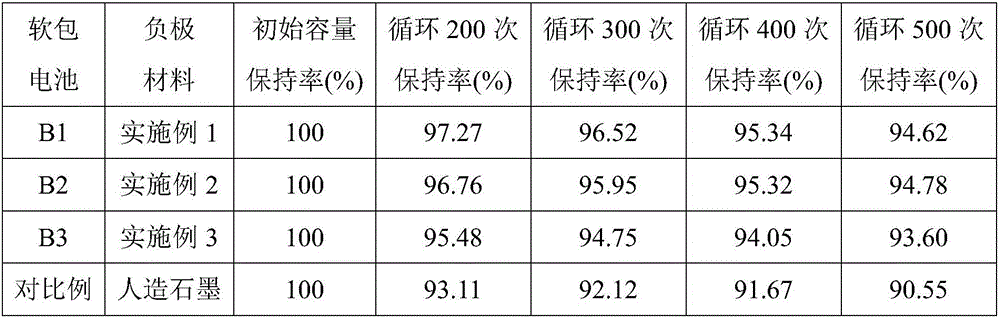

[0050] The lithium-ion battery silicon composite negative electrode material of the present embodiment includes a matrix mixture and a carbon layer coated on the surface of the matrix mixture; the matrix mixture includes the following components in parts by weight: 3 parts of nano-silicon, LiAlO 2 3 parts, 3 parts of hollow carbon spheres, 85 parts of modified artificial graphite. Wherein, the particle diameter of the nano-silicon is 50nm; the diameter of the hollow carbon sphere is 500nm, and the wall thickness is 70-100nm.

[0051] The silicon composite negative electrode material is granular; the particle diameter D50 is 8 μm; wherein, the thickness of the carbon layer is 0.5-2 μm. The mass ratio of the matrix mixture to the carbon layer is 100:5. The carbon layer includes carbon nanowires, carbon nanotubes and amorphous carbon; the mass percentage of the carbon nanowires in the carbon layer is 70%, and the balance is carbon nanotubes and amorphous carbon. The carbon nan...

Embodiment 2

[0059] The lithium-ion battery silicon composite negative electrode material of the present embodiment includes a matrix mixture and a carbon layer coated on the surface of the matrix mixture; the matrix mixture includes the following components in parts by weight: 1 part of nano-silicon, LiAlO 2 1 part, 1 part of hollow carbon sphere, 70 parts of modified natural graphite. Wherein, the particle size of the nano-silicon is 20nm; the diameter of the hollow carbon sphere is 300nm, and the wall thickness is 50-80nm.

[0060] The silicon composite negative electrode material is granular; the particle diameter D50 is 13 μm; wherein, the thickness of the carbon layer is 1-4 μm. The mass ratio of the matrix mixture to the carbon layer is 100:20. The carbon layer includes carbon nanowires, carbon nanotubes and amorphous carbon; the mass percentage of the carbon nanowires in the carbon layer is 80%, and the balance is carbon nanotubes and amorphous carbon. The carbon nanowire is sol...

Embodiment 3

[0066] The lithium-ion battery silicon composite negative electrode material of the present embodiment includes a matrix mixture and a carbon layer coated on the surface of the matrix mixture; the matrix mixture includes the following components in parts by weight: 5 parts of nano-silicon, LiAlO 2 5 parts, 5 parts of hollow carbon spheres, 95 parts of modified artificial graphite. Wherein, the particle diameter of the nano-silicon is 20nm; the diameter of the hollow carbon sphere is 800nm, and the wall thickness is 100-200nm.

[0067] The silicon composite negative electrode material is granular; the particle diameter D50 is 18 μm; wherein, the thickness of the carbon layer is 2˜5 μm. The mass ratio of the matrix mixture to the carbon layer is 100:30. The carbon layer includes carbon nanowires, carbon nanotubes and amorphous carbon; the mass percentage of the carbon nanowires in the carbon layer is 90%, and the balance is carbon nanotubes and amorphous carbon. The carbon na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com