A kind of preparation method of composite conductive agent used in lithium ion battery

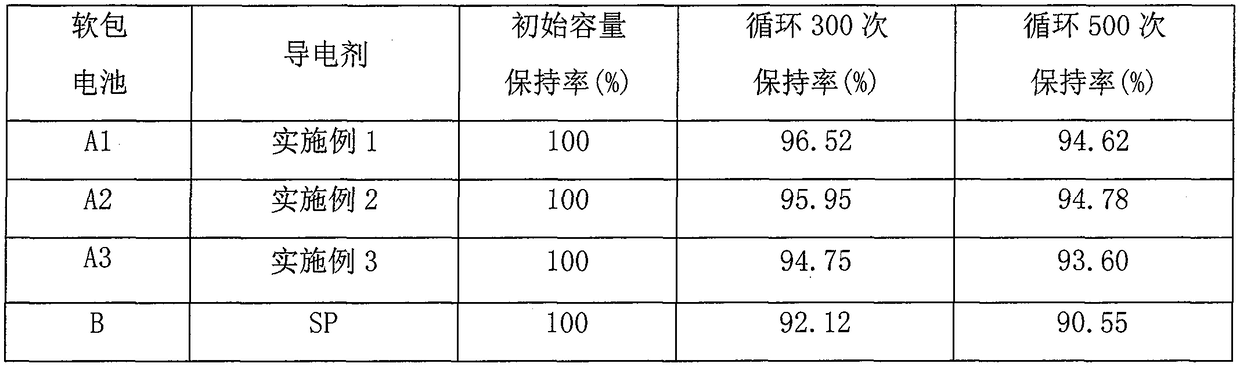

A technology of composite conductive agent and composite solvent, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor synergistic effect and single function, and achieve the effects of strong conductivity, improved cycle performance, and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 10 grams of aniline, 15 grams of phenylacetylene, and 30 grams of phenyllithium were added to 500 grams of chloroform and stirred evenly to prepare an organic composite solvent A. Add 15 grams of ammonium persulfate, 30 grams of hydrochloric acid, and 60 grams of acidified carbon nanotubes into 1000 grams of double distilled water and stir evenly to prepare an aqueous composite solvent. Move the water-based composite solvent into a jar, then slowly pour the organic composite solvent on the surface of the aqueous composite solvent, shake the jar under nitrogen for 10 minutes, and finally obtain a polymer at the water / oil interface. The material was taken out and washed with ethanol and double distilled water respectively to prepare a composite conductive agent.

Embodiment 2

[0030] Add 10 grams of aniline, 10 grams of phenylacetylene, and 10 grams of phenyllithium into 500 grams of ether and stir evenly to prepare organic composite solvent A. 10 grams of ammonium persulfate, 10 grams of hydrochloric acid, and 50 grams of acidified carbon nanotubes were added to 1000 grams of double distilled water and stirred evenly to prepare an aqueous composite solvent. Move the water-based composite solvent into a jar, then slowly pour the organic composite solvent on the surface of the aqueous composite solvent, shake the jar under nitrogen for 10 minutes, and finally obtain a polymer at the water / oil interface. The material was taken out and washed with ethanol and double distilled water respectively to prepare a composite conductive agent.

Embodiment 3

[0032] 10 grams of aniline, 20 grams of phenylacetylene, and 50 grams of phenyllithium were added to 500 grams of ether and stirred evenly to prepare an organic composite solvent A. 20 grams of ammonium persulfate, 50 grams of hydrochloric acid, and 100 grams of acidified carbon nanotubes were added to 1000 grams of double distilled water and stirred evenly to prepare an aqueous composite solvent. Move the water-based composite solvent into a jar, then slowly pour the organic composite solvent on the surface of the aqueous composite solvent, shake the jar under nitrogen for 10 minutes, and finally obtain a polymer at the water / oil interface. The material was taken out and washed with ethanol and double distilled water respectively to prepare a composite conductive agent.

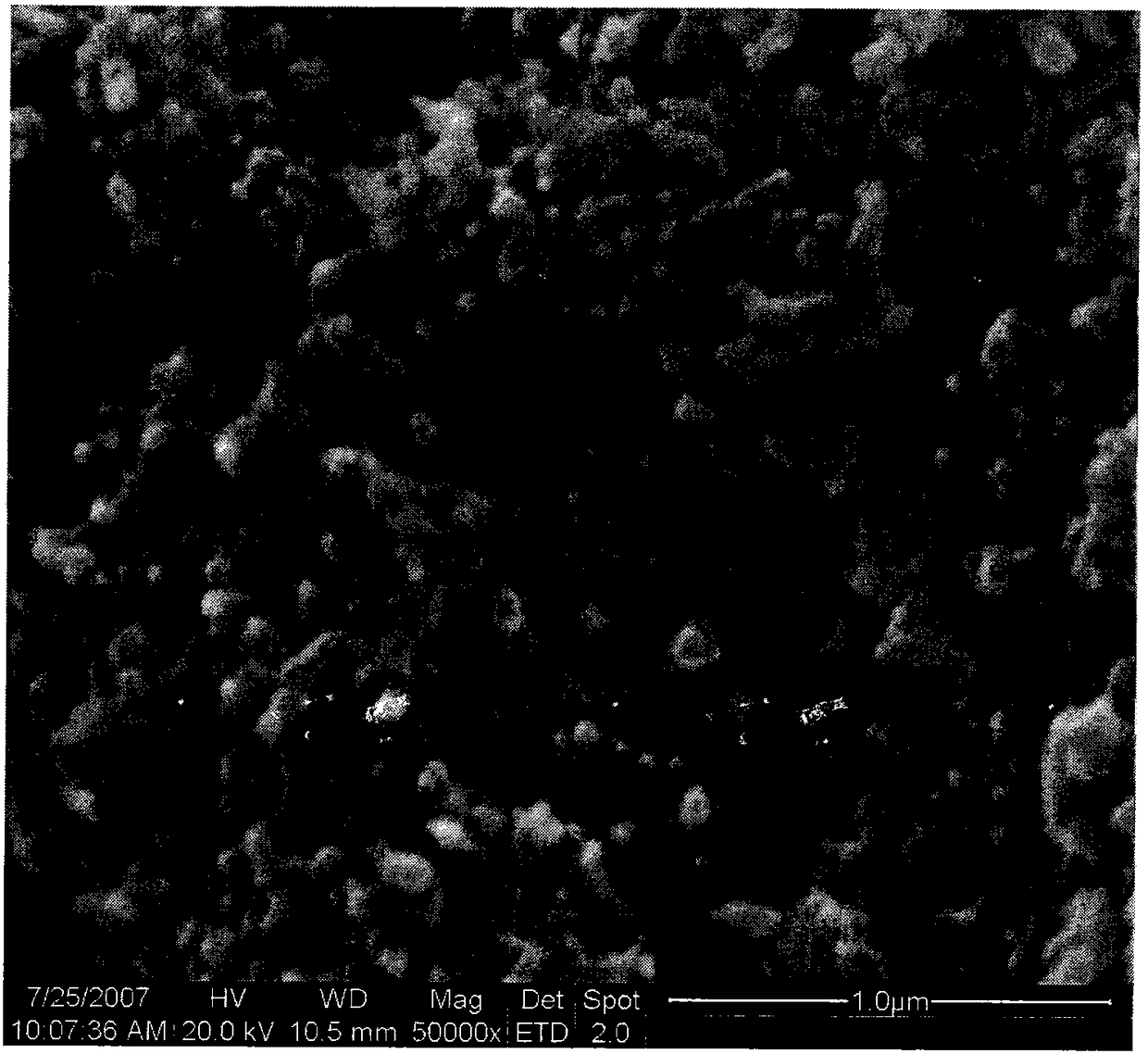

[0033] figure 1 It is the scanning electron microscope SEM test figure of embodiment 1, the scanning electron microscope SEM test figure of embodiment 2-3 and figure 1 Similar, not otherwise given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com