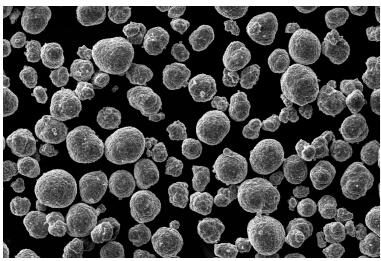

A preparation method of nanoporous lithium-rich lithium iron phosphate material

A lithium iron phosphate, nano-porous technology, applied in the direction of nano-technology, structural parts, electrical components, etc., can solve the problems of poor liquid absorption capacity, poor conductivity, low initial efficiency, etc., achieve strong liquid absorption and retention capacity, improve Cycle performance, the effect of high cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

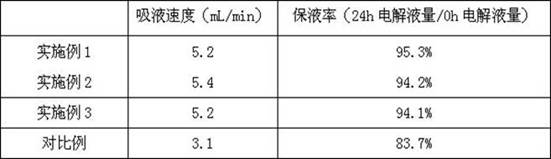

Embodiment 1

[0020] 1) Preparation of lithium powder composite A:

[0021] First, 95 g of propylene carbonate is dissolved in 500 mL of n-hexane organic solvent, then add 5 g of lithium powder and 0.5 g sif 4 , Mix evenly to obtain lithium powder composite A;

[0022] 2) Preparation of lithium iron phosphate phosphate:

[0023] 13.32G lico 3 (0.18 mol), 72.72G Fe (NO 3 ) 3 · 9h 2 O (0.18 mol), 18.72G LiH 2 PO 4 (0.18 mol) was mixed with 800 GN-methylpyrrolidone, then 3 g of amino lithium was adjusted to a pH of 9, then add 20 g of lithium powder composite A, which was transferred to a high pressure reaction kettle, and at temperatures 200 ° C, Reaction 12H, filtered to give a lithium phosphate precursor material B;

[0024] 3) Preparation of multi-porous lithium phosphate composites:

[0025] The 80 g of a lithium phosphate precursor material B was added to a glucose solution of 500 ml of a concentration of 10%, and the spherium-rich lithium phosphate was mixed and uniformly sprayed, and the b...

Embodiment 2

[0027] 1) Preparation of lithium powder composite A:

[0028] First weigh 90 g of polymethylsiloxane dissolved in 500 mL of n-hexane organic solvent, then add 10 g of lithium powder and 0.1 gsnf. 4 , Mix evenly to obtain lithium powder composite A;

[0029] 2) Preparation of lithium iron phosphate precursor material B:

[0030] 1.2 g liOH (0.05 mol), 77.05G FEC 6 Hide 5 O 7 · 5h 2 O (0.23mol), 23.92g Lih 2 PO 4 (0.23 mol) was added to 500 mlN-methylpyrrolidone, then 1 g of amino lithium was added to the pH of 8 to 10, then the lithium powder composite material A was added, and transferred to a high pressure reaction kettle, and at a temperature of 150 ° C, Reaction 24 h, filtered to obtain a lithium phosphate precursor material B;

[0031] 3) Preparation of multi-porous lithium phosphate composites:

[0032] 50 g of a lithium phosphate precursor material B was placed in a glucose solution of 500 g of a glucose solution to a glucose solution to prepare a pellet-rich lithium phospha...

Embodiment 3

[0034] 1) Preparation of lithium powder composite A:

[0035] First, 99 g of polyacrylate is dissolved in 500 mL of n-hexane organic solvent, then add 1 g of lithium powder and 1 g of whole fluoropylmine, stir evenly to obtain a lithium powder composite A;

[0036] 2) Preparation of lithium iron phosphate precursor material B:

[0037] 9.6 g liOH (0.4mol), 67G FEC 6 Hide 5 O 7 · 5h 2 O (0.2mol), 20.8g lih 2 PO 4 (0.2 mol) Adding an amino lithium was added to the oily solvent to add amino lithium adjusted to pH 10, then add 30 g of lithium powder composite A, transferred to a high pressure reaction kettle, and at a temperature of 300 ° C, reaction for 2 h, filtration is rich Lithium iron phosphate precursor material B;

[0038] 3) Preparation of multi-porous lithium phosphate composites:

[0039] The 100 g of a lithium phosphate precursor material B was placed in a 500 ml concentration of 10% glucose aqueous solution mixed uniform spray drying to prepare a pellet-rich lithium phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com