Patents

Literature

82 results about "Lithium amide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium amide or lithium azanide is an inorganic compound with the chemical formula LiNH₂. It is a white solid with a tetragonal crystal structure.

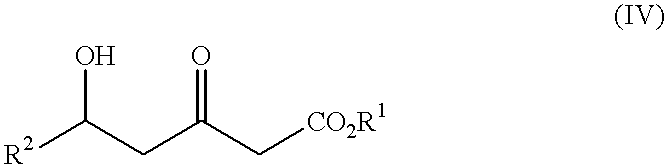

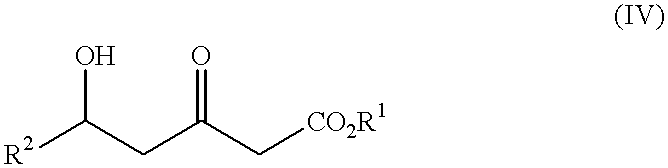

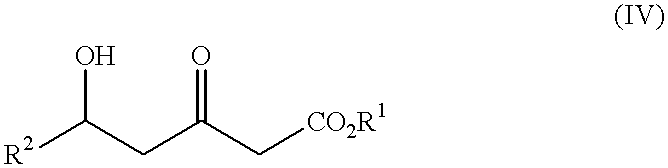

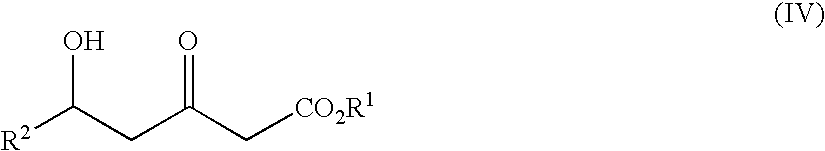

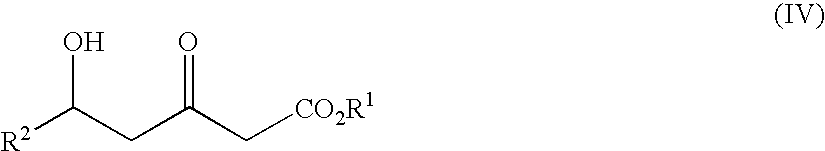

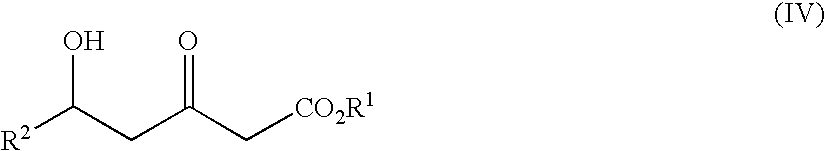

Processes for the preparation of 5-hydroxy-3-oxopentanoic acid derivatives

InactiveUS6340767B1Increase productionGreat advantageCarboxylic acid nitrile preparationOrganic compound preparationAcetic acid3-Hydroxypropionic acid

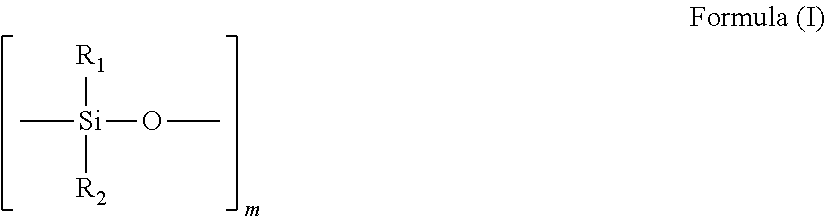

This invention provides a process for producing a 5-hydroxy-3-oxopentanoic acid, a useful pharmaceutical intermediate, easily from a readily available, inexpensive starting material without using any extraordinary production equipment such as a very-low-temperature reactor.Thus, this invention provides a process for producing a 5-hydroxy-3-oxopentanoic acidwhich comprises permitting a lithium amide to act upon a mixture of an acetic acid ester and a 3-hydroxypropionic acid derivative at not below -20° C.Further, this invention also provides a process for producing a 5-hydroxy-3-oxopentanoic acidwhich comprises treating a mixture of an acetic acid ester and a 3-hydroxypropionic acid derivative with a Grignard reagent to prepare a mixture of a compound and an acetic acid ester of the above formula (I),and permitting a lithium amide to act upon the mixture at a temperature not below -20° C.

Owner:KANEKA CORP

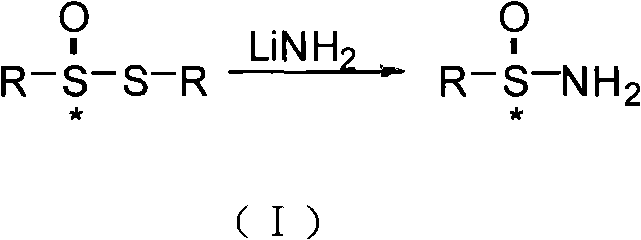

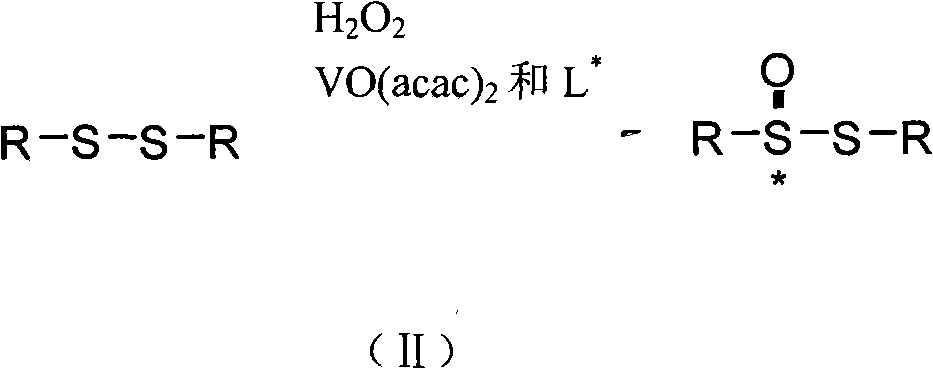

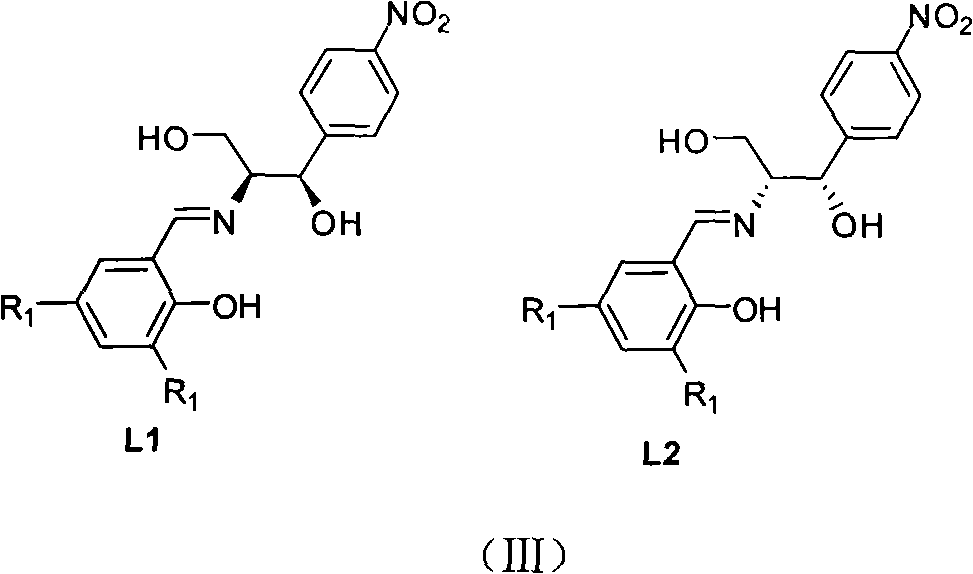

Method for synthesizing chiral sulfenamide

InactiveCN101525308AReduce dosageLower synthesis costOrganic-compounds/hydrides/coordination-complexes catalystsAsymmetric synthesesThiosulfinateSalicylaldehyde

The invention discloses a method for synthesizing chiral sulfonamide. In the method, chiral thiosulfinate is taken as a raw material and reduced with liquid ammonia containing lithium amide to obtain the chiral sulfonamide, and a reaction formula is as above, wherein, R is one of C1-C10 alkyl, phenyl, p-cresyl, o-cresyl, metal-cresyl, p-ethyl benzyl, p-tertiary-butyl phenyl, p-acetyl phenyl, o-acetyl phenyl and naphthyl. The method sequentially comprises the following steps: preparing the lithium amide; dropwise adding the lithium amide to chiral thiosulfinate solution and stirring for reaction; and adding ice to obtained mixture after the reaction, extracting, combining organic phases and eliminating solvents, and crystallizing to obtain the chiral sulfonamide. The method has the advantages that synthesis cost is reduced by an oxidation method in the presence of a chiral catalyst; a ligand is a condensation product of cheap and available chloromycetin derivative and salicylaldehyde derivative; and reaction steps are less, the reaction conditions are mild and post-treatment is simple.

Owner:上海立科化学科技有限公司

Non-aqueous electrolyte and non-aqueous electrolyte secondary power source comprising the same

InactiveUS20100285373A1Excellent non-flammabilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsAlkoxy groupSolvent

This invention relates to a non-aqueous electrolyte having high non-combustibility and a non-aqueous electrolyte secondary power source having high safety and exhibiting stable performance even under high load conditions or low-temperature conditions, and more particularly to a non-aqueous electrolyte characterized by comprising a cyclic phosphazene compound represented by the following general formula (I):(NPR2)n (I)[wherein Rs are independently fluorine, an alkoxy group or an aryloxy group and n is 3-4], a non-aqueous solvent, LiPF6 and at least one lithium amide selected from the group consisting of Li(FSO2)2N, Li(CF3SO2)2N and Li(C2F5SO2)2N, as well as a non-aqueous electrolyte secondary power source comprising the non-aqueous electrolyte, a positive electrode and a negative electrode.

Owner:BRIDGESTONE CORP

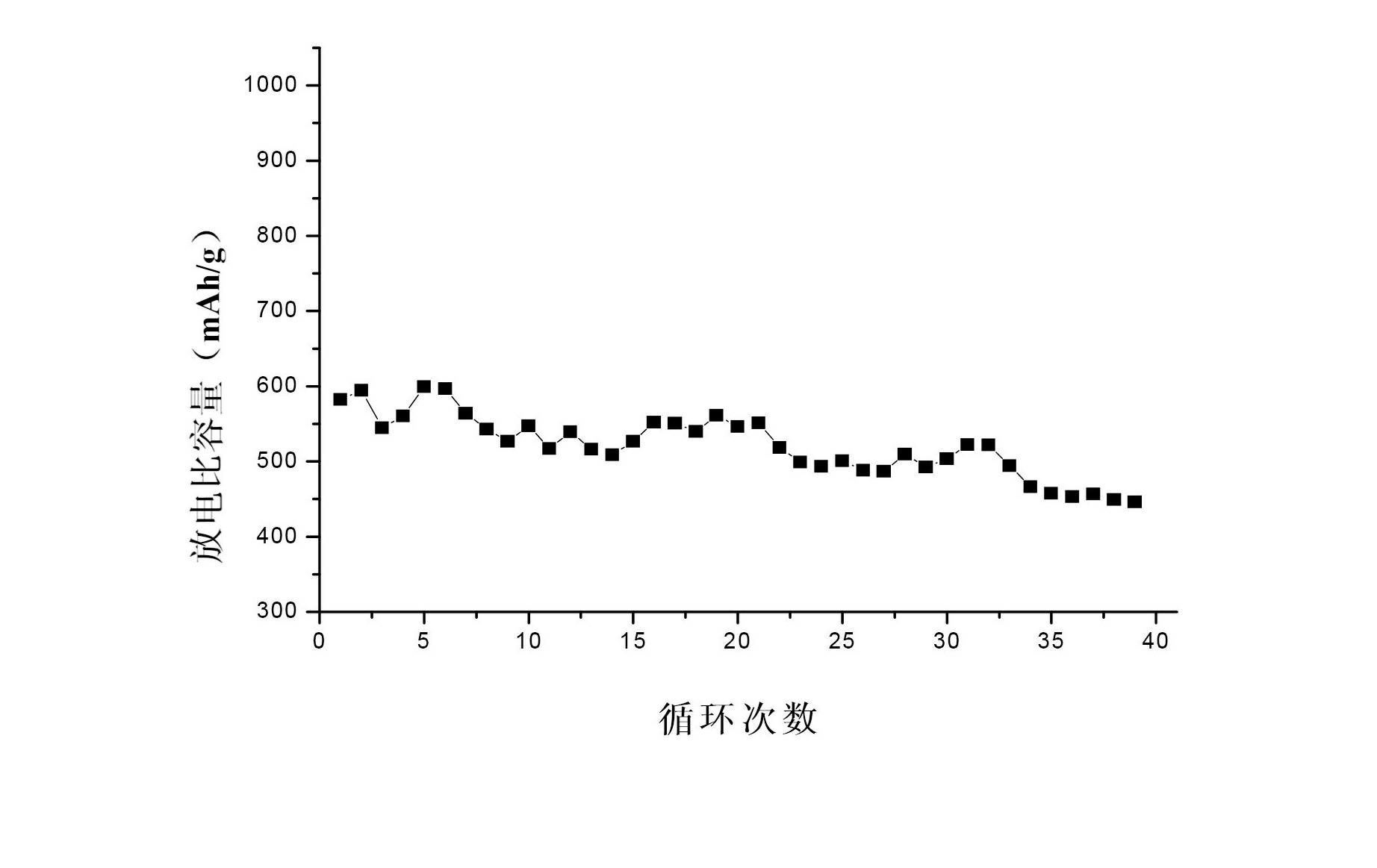

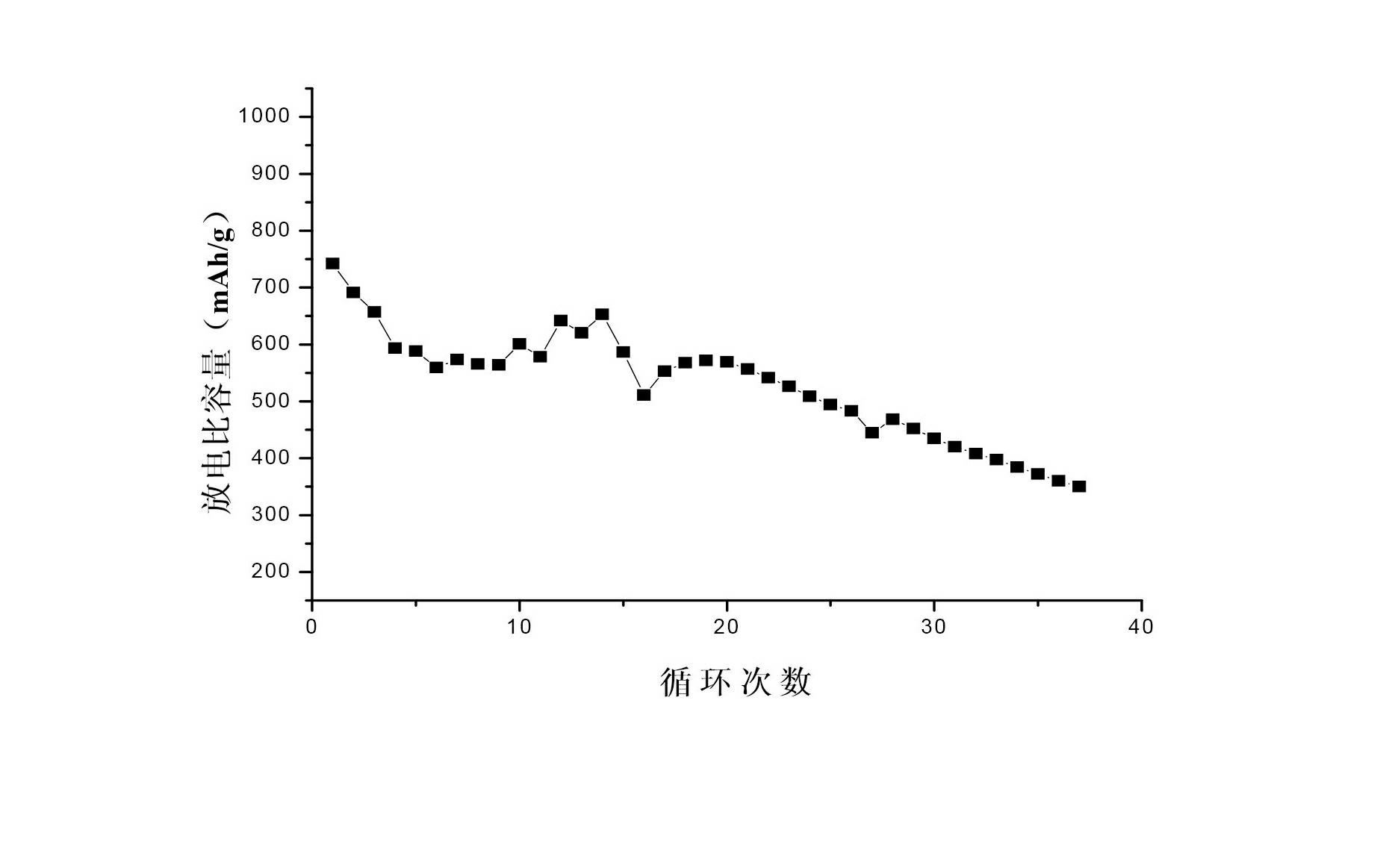

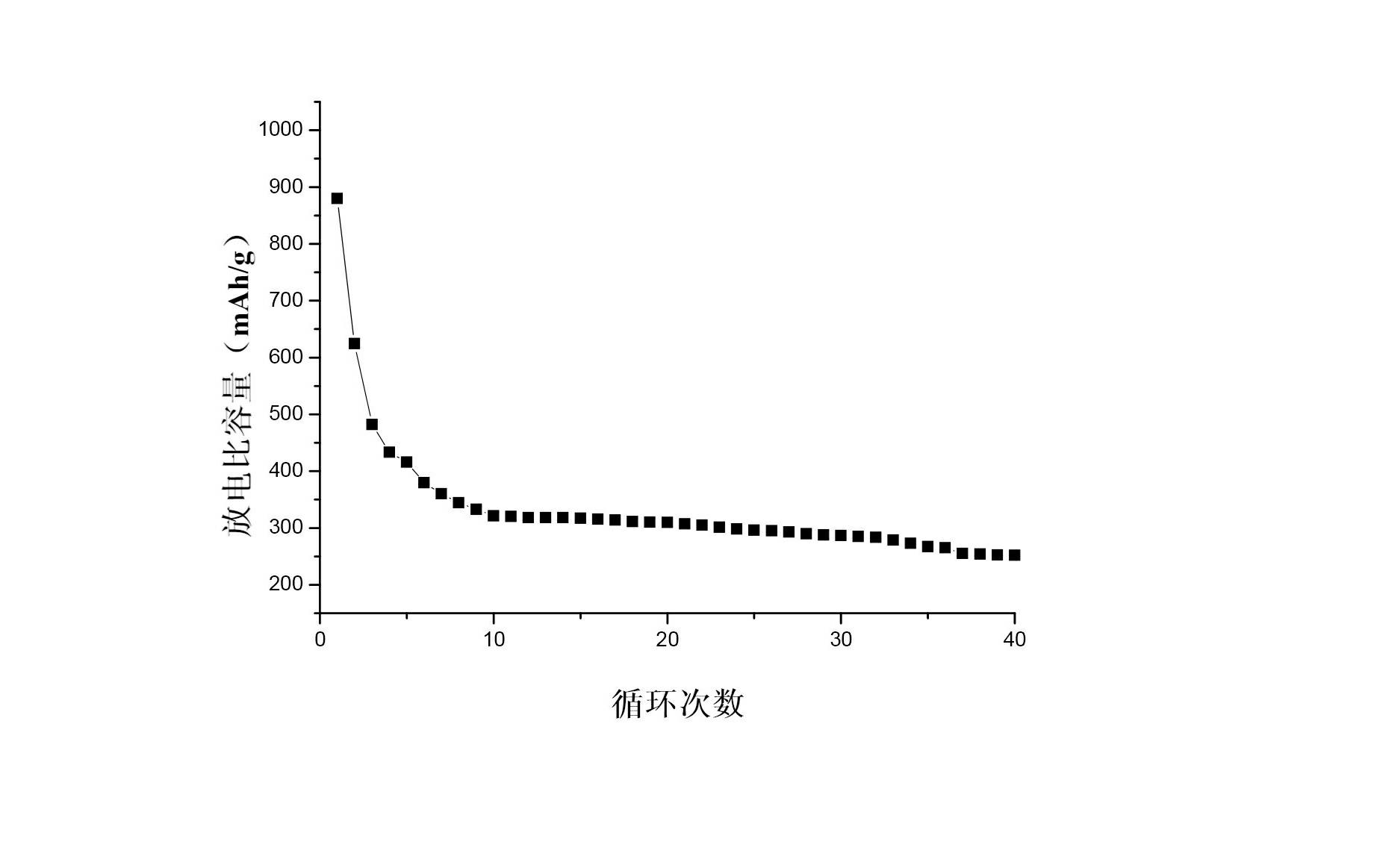

Electrolyte used for Li-S battery, Li-S battery and method for preparing electrolyte membrane contained in same

The invention discloses an electrolyte used for a Li-S battery, comprising an electrolyte membrane and electrolyte, wherein the electrolyte membrane takes PVDF (polyvinylidene fluoride) or PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene) as a main chain, the side chain of the main chain comprises one or more than one of lithium sulphonate group, lithium carboxylate group and lithium amide group; and the electrolyte is mixed solution containing at least one of 1,3-dioxolame, dimethoxyethane, diethylene glycol dimethyl ether, triethylene glycol dimethyl ether and sulfolane. The electrolyte, an anode and a cathode form the Li-S battery in the invention. The method for preparing the electrolyte membrane contained in the electrolyte comprises the following steps: firstly dissolving PVDF or PVDF-HFP, heating and stirring, and casting to obtain a membrane; treating the membrane with KOH / ethyl alcohol solution, then transferring the membrane into mixed solution of graft monomer / tetrahydrofuran, and adding formylamine peroxide for grafting; and cleaning the grafted membrane and soaking to obtain the electrolyte membrane. The electrolyte membrane in the invention is simple to prepare,the cost is low, the loss of active substance can be reduced, and the cycle life of the battery can be prolonged.

Owner:NAT UNIV OF DEFENSE TECH

Process for the preparation of 5-hydroxy-3-oxopentanoic acid derivatives

InactiveUSRE39333E1Carboxylic acid nitrile preparationOrganic compound preparationAcetic acid3-Hydroxypropionic acid

Owner:KANEKA CORP

Silicon wafer cleaning agent and use method thereof

InactiveCN101880609AEasy to operateWill not bring inSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsOrganic baseStandard electrode potential

The invention discloses a silicon wafer cleaning agent and a use method thereof. The silicon wafer cleaning agent consists of oxidant, organic base, penetrant and water, and the volume ratio of the components is as follows: oxidant : organic base : penetrant : water equal to 0.02-0.1:1-4:0.5-1:30-50; the standard electrode potential of the oxidant is not less than 1.7V, and the oxidant is ozone or hydrogen peroxide; the organic base is selected from one or more of the following components: triethanolamine, sodium alkoxide, sodium alkyl, lithium alkyl, lithium amide and quaternary ammonium base; and the penetrant is fatty alcohol-polyoxyethylene ether or sodium diethylhexyl sulfosuccinate. The cleaning agent can be simply operated, silicon wafer cleaning does not become complex, the cost is low, no pollution is generated, and the cleaning agent cannot bring impurities to stain silicon wafers, and is environment-friendly.

Owner:GD SOLAR

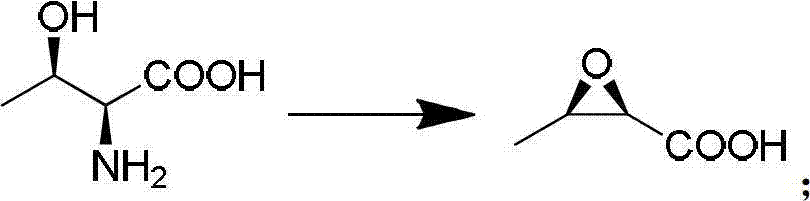

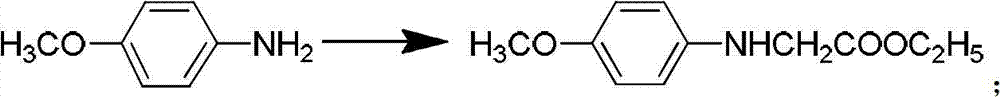

Synthetic method for penem and carbapenem antibiotic type key intermediate 4AA

InactiveCN102827199AEasy to operateAdvanced technologyGroup 4/14 element organic compoundsSNiAntibiotic Y

The invention relates to a synthetic method for a penem and carbapenem antibiotic type key intermediate 4AA, belonging to the technical field of medicine. The method comprises the following steps of: reacting L-threonine with sodium nitrite-hydrochloric acid to generate a diazo compound; performing an internal nucleophilic substitution reaction on the diazo compound under the action of sodium hydroxide; acidifying to obtain epoxy sodium butanoate; acidifying to obtain epoxy butyrate; reacting the epoxy butyrate with p-methoxyanilinoethyl acetate to obtain a condensation product; generating a quaternary ring compound from the condensation product under the actions of hexamethyldisilazane and lithium amide; and performing hydroxy protection, hydrolysis, oxidative decarboxylation and ozonization deprotection on the ring compound to obtain 4AA. The process has the advantages of readily-available raw material, mild reaction conditions, short reaction time, low pollution, high yield and the like, and is suitable for industrial production.

Owner:CHINA THREE GORGES UNIV

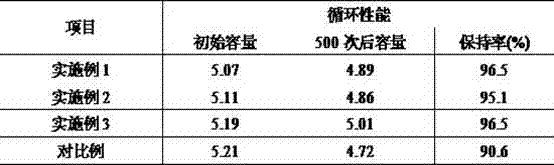

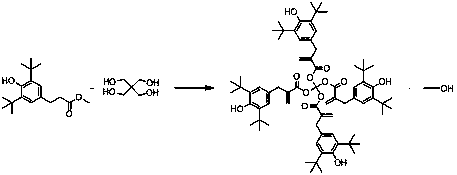

Method for synthesizing antioxidant 1076 by use of novel titanium-containing catalyst

InactiveCN105348103AImprove catalytic performanceSimplify the process of recrystallizationPreparation by ester-hydroxy reactionPotassium hydroxidePhenol

A method for synthesizing an antioxidant 1076 by the use of a novel titanium-containing catalyst comprises the following steps: 2,6-phenol and methyl ester are subjected to an addition reaction to prepare 3,5-ester; 3,5-ester and octadecyl alcohol are subjected to an ester-exchange reaction to generate an antioxidant 1076; and finally, recrystallization is carried out to obtain a product. The method is characterized in that a catalyst used in the addition reaction and the ester-exchange reaction is a titanium-containing catalyst. The novel titanium-containing catalyst used in the invention has good catalytic performance in the ester-exchange reaction for synthesis of the antioxidant 1076. By the method, product content reaches 99% and above, light transmittance 425 nm reaches 98.8% and above, and yield reaches 97% and above. The novel titanium catalyst has more excellent performance than catalysts such as sodium methylate, potassium hydroxide, lithium amide, organo-tin and the like when used in the esterification reaction of the antioxidant 1076. By the use of the titanium catalyst, the reactions are accelerated, the process of aftertreatment-recrystallization is simplified, and high yield is obtained.

Owner:TIANJIN CHENGUANG CHEM

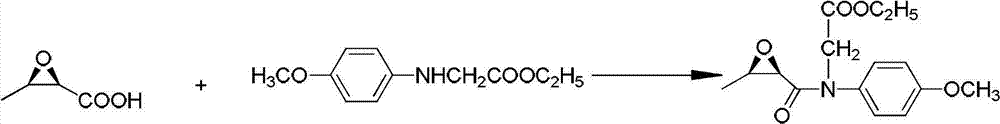

Lithium amide soapstone nano particles modified by polyethylene glycol-folic acid as well as preparation and application of lithium amide soapstone nano particles

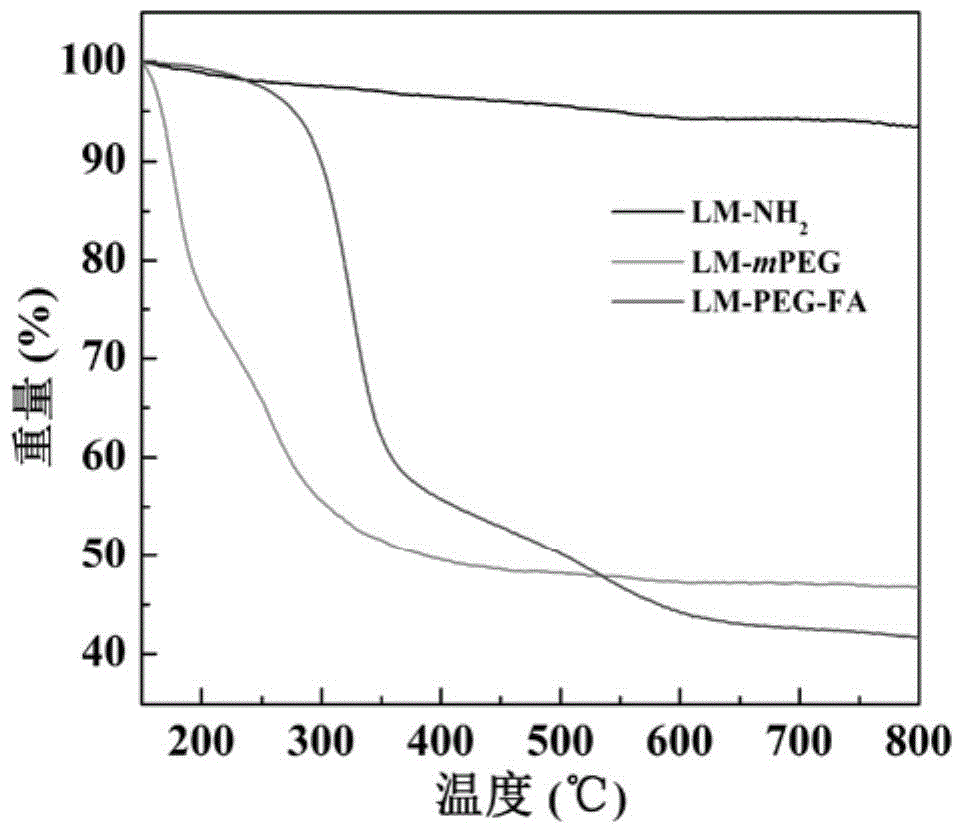

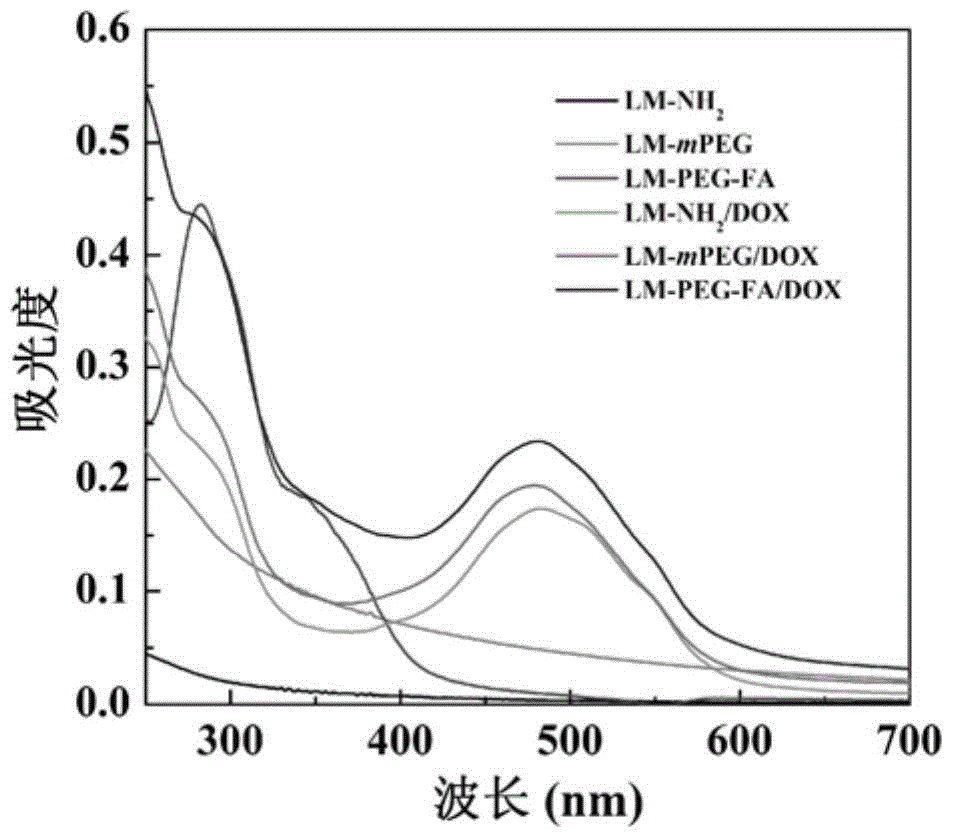

InactiveCN104147608ATargetedEnhanced inhibitory effectOrganic active ingredientsPowder deliverySilanesPolyethylene glycol

The invention relates to lithium amide soapstone nano-particles modified by polyethylene glycol-folic acid as well as preparation and application of the lithium amide soapstone nano particles. Lithium amide soapstone is lithium soapstone modified by (3-aminopropyl) ethoxydimethyl-silane APMES; the mol ratio of polyethylene glycol to folic acid is (1:0.4)-(1:0.8); and the mass percentage of polyethylene glycol-folic acid is 45-55%. The preparation disclosed by the invention comprises the following steps of dissolving folic acid in a solvent, adding 1-(3-dimethylaminopropyl)-3-ethyl carbodiimide hydrochloride EDC, stirring to obtain mixed solution, adding the mixed solution into polyethylene glycol solution drop by drop, stirring in 2-3 d, dialyzing, freezing, drying, and obtaining polyethylene glycol-folic acid PEG-FA; and adding EDC into PEG-FA solution, stirring for 2-4 h, adding into aqueous solution of the lithium amide soapstone nano particles drop by drop, magnetically stirring in 2-3 d and dialyzing, thereby obtaining the lithium amide soapstone nano particles modified by polyethylene glycol-folic acid. The lithium amide soapstone nano particles modified by polyethylene glycol-folic acid are applied to drug load, have the advantages of simple preparation method, moderate condition and wide application range, and have good market prospect.

Owner:DONGHUA UNIV

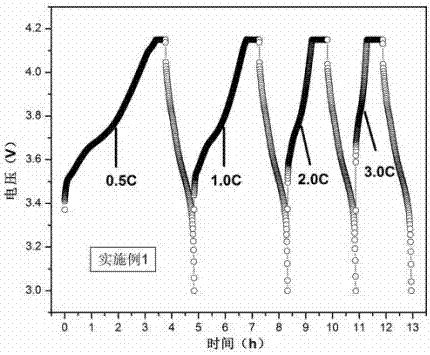

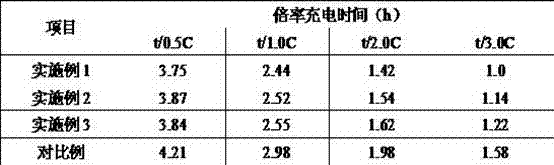

Composite cathode pole piece of lithium ion battery and lithium ion battery thereof

InactiveCN106992282AGood compatibilityReduce contact resistanceCell electrodesSecondary cellsElectrical batteryPole piece

The invention belongs to the field of lithium ion battery preparation, and particularly discloses a composite cathode pole piece of a lithium ion battery and the lithium ion battery thereof. The composite cathode pole piece is composed of a cathode pole piece, an organic lithium compound and inorganic lithium compound which are coated at both sides of the cathode pole piece. The inorganic lithium compound is a nitrogen-containing lithium compound, such as lithium nitride and lithium amide; the electronic conductivity and structural stability of the inorganic lithium compound are improved by using the nitrogen atom, and the lithium ion transmission rate during the charging and discharging processes is improved by using the lithium ion therein; the organic lithium compound, such as lithium acetate, lithium alkoxy, alkyl bislithium carbonate, can improve the compatibility between the material surface thereof and electrolyte, and the high-temperature stabilization performance; for the surface of the prepared composite cathode pole piece contains sufficient lithium ion, the cathode pole piece can avoid the formation of lithium dendrites of the lithium ion battery during the charging and discharging processes, and the improve the safety performance thereof; the prepared composite cathode pole piece is applied to the lithium ion battery, and the rate capability and safety performance of the lithium ion battery can be improved.

Owner:JIANGSU LENENG BATTERY INC

Application of amino aryloxy rare-earth metal-lithium amide used as catalyst

InactiveCN102755906AGood substrate adaptabilityHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRare earthMethyl group

The invention discloses application of amino aryloxy rare-earth metal-lithium amide used as a catalyst to catalyze amidation reaction of aldehyde and amine to prepare acid amide or bisamide. A general formula of the amino aryloxy rare-earth metal-lithium amide is [NO]2Ln[N(TMS)2][Li9(THF)]2; in the formula, [NO] represents amino aryloxy ligand; X is selected from one of hydrogen, C1-C4 saturated alkyl or halogen; R2 and R3 are respectively selected from one of methyl or tertiary butyl; Ln represents a central ion and is selected from one of praseodymium, neodymium, samarium, ytterbium or yttrium, and TMS (tetramethylsilane) is tetramethylsilane. The complex is used as the catalyst for catalyzing the aldehyde and amine to synthetize the acid amide. The dosage of the catalyst is less, the reaction condition is mild and the reaction time is short.

Owner:SUZHOU UNIV

Method for preparing hindered phenolic antioxidant by using composite catalyst

ActiveCN109534990AKeep the colorMinimize impact on product qualityPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPentaerythritolPhenolic antioxidant

The invention discloses a method for preparing a hindered phenolic antioxidant by using a composite catalyst, belonging to the field of preparation of antioxidants. The method comprises the followingsteps: evenly mixing 3-(3, 5-di-tert-butyl-4-hydroxyphenyl) methyl propionate with pentaerythritol, and then adding the lithium amide / lithium acetate composite catalyst for catalyzing, distilling, crystallizing, filtering and drying to obtain the hindered phenolic antioxidant 1010. The hindered phenolic antioxidant prepared by the method effectively avoids the influence, caused by adopting an organotin catalyst, on a human body and the environment; compared with single use of lithium amide or lithium acetate as a catalyst, the method is rapider in reaction speed, and guarantees the color of reaction liquid, thus guaranteeing the product quality.

Owner:LIAONING DINGJIDE PETROCHEM

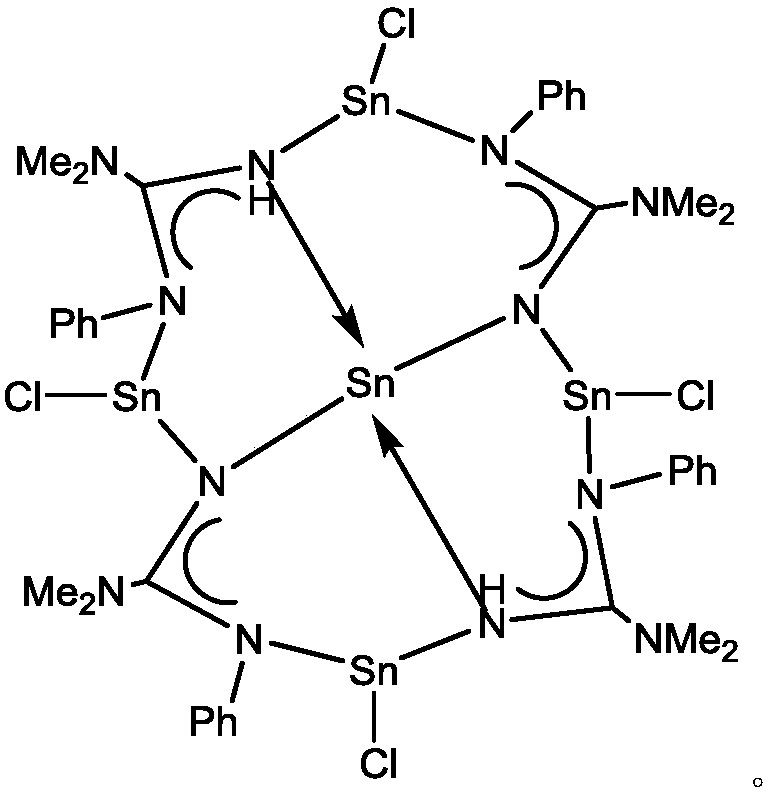

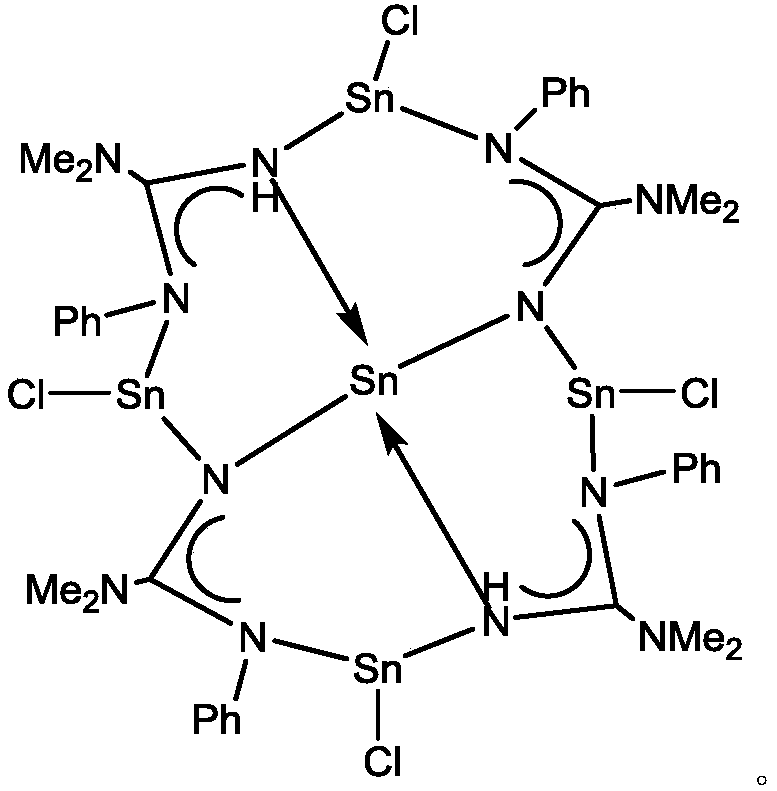

Five-core tin (II) compound and preparation method and application thereof

ActiveCN109666039ANovel structureImprove stabilityTin organic compoundsOrganic compound preparationNitrogen gasAniline

The invention provides a five-core tin (II) compound and a preparation method and an application thereof. A synthetic process of the compound comprises the following steps: under the protection of a nitrogen gas, adding trimethyl silicon-based benzene (phenyl) lithium amide to a reaction vessel, adding ethyl ether for dissolving, in a condition of an acetone bath, adding dimethylaminonitrile, reacting overnight, and adding SnCl2 in the condition of the acetone bath, slowly warming to a room temperature, reacting overnight, stewing, filtering, concentrating filtrate in vacuum, crystalizing in the room temperature, and separating out a colorless crystal, to obtain the five-core tin (II) compound, wherein a mole ratio of the trimethyl silicon-based benzene (phenyl) lithium amide, the dimethylaminonitrile and the SnCl2 is 1:1:1-1.25. The compound can be used as a catalyst, and used for catalyzing a reaction of generating guanidine by aniline and N,N'-diisopropyl carbodiimide addition, andhas better application prospect.

Owner:SHANXI UNIV

Process method for synthetizing tert-butyl sulfinamide

The invention relates to a method for synthetizing an organic compound. A process method for synthetizing tert-butyl sulfinamide comprises the following steps: (a) under the temperature of between 50 DEG C below zero to 70 DEG C below zero, adding triphenyl methyl halide into liquid ammonia to obtain N methyl triphenyl ammonia; (b) under the temperature of between 60 DEG C below zero and 70 DEG Cbelow zero, adding n-butyl lithium into organic solution of N methyl triphenyl ammonia to obtain organic solution of N methyl (triphenyl) lithium amide; (c) at the temperature of between 50 DEG C below zero and 70 DEG C below zero, dropwise adding organic solution of (S)-tert-butyl sulfinic acid tert-butyl thioester into the N-methyl (triphenyl) lithium amide, quenching the mixture by using water, carrying out deodorization by using dimethyl sulfate, destroying excessive dimethyl sulfate by using ammonia and carrying out post treatment to obtain (S)-N-methyl (triphenyl) tert-butyl sulfinamide; and (d) taking the product in the step (c), adding dilute acid into the product, adjusting the pH value of the mixture to 3, neutralizing the mixture by using alkaline solution until the pH value isbetween 13 and 14 and carrying out post treatment to obtain (S)-tert-butyl sulfinamide. The process method for synthetizing the tert-butyl sulfinamide has simple and convenient operation and good process stability, avoids copious cooling at the low or ultralow temperature, reduces the using amount of ammonia, removes foul odour and is easy to realize industrial production.

Owner:DALIAN NETCHEM CHIRAL TECH

Lead-free solder scaling powder and preparation method thereof

InactiveCN104985355AIncrease moistureWelding/cutting media/materialsSoldering mediaMetallurgySilanes

The invention discloses lead-free solder scaling powder and a preparation method thereof. The lead-free solder scaling powder comprises organic acid, nonionic surface active agents, silane, fatty acid, lithium amide, trialkyborane, carbon disulfide and rosin. The lead-free solder scaling powder can improve the wettability of Sn-Ag-Cu series lead-free solder and is environmentally friendly. In addition, the preparation method of the lead-free solder scaling powder is simple in step, and raw materials are easy to obtain.

Owner:WUHU ADER CONVEYOR MACHINERY

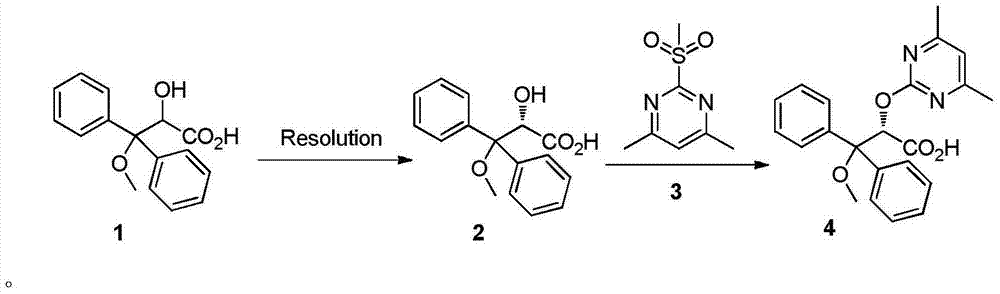

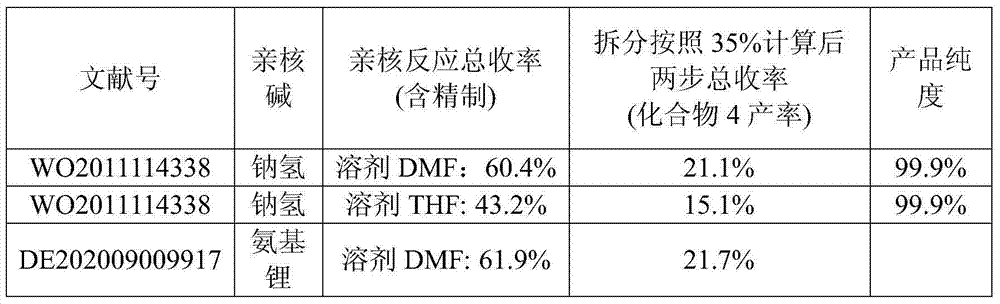

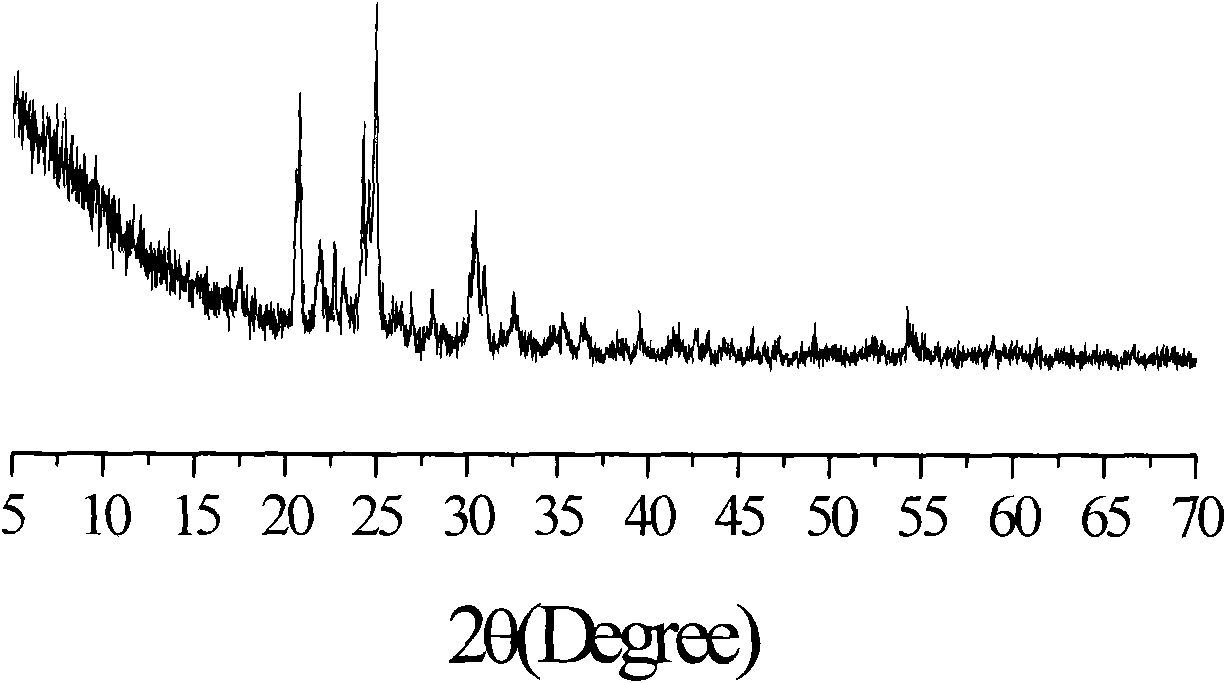

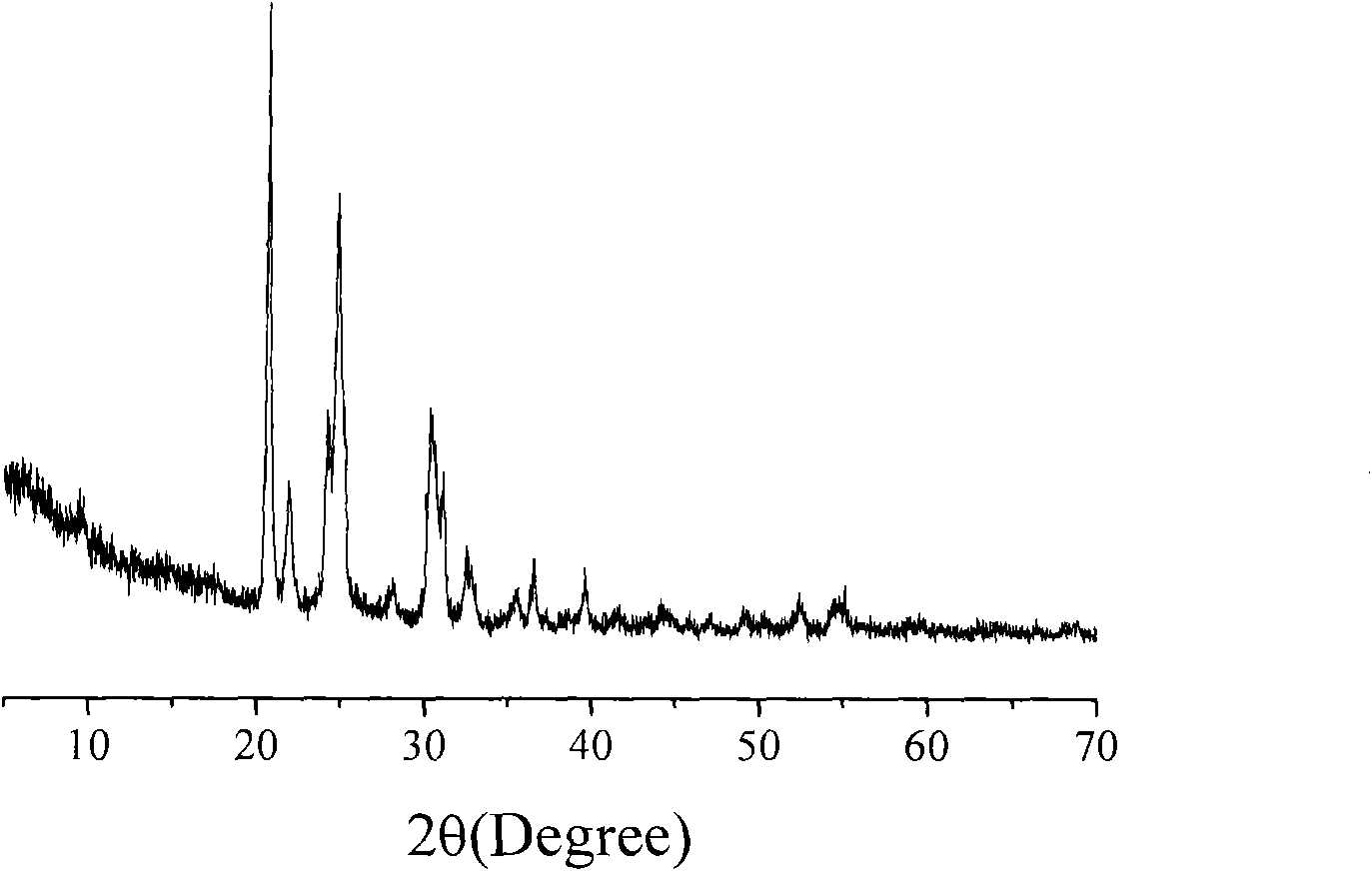

Synthetic method of ambrisentan

The invention relates to a synthetic method of ambrisentan and belongs to the technical field of medicine chemistry. The method comprises the steps of taking a racemoid 1 as a reactant, performing L-proline methyl ester hydrochloride resolution on a compound 1 to obtain a crude product of compound 2, performing nucleophilic reaction on the crude product of the compound 2 and a compound 3 to obtain compound 4. After an enantiomer of the compound 2 of compound 1 is filtered our by resolution, methyl tertiary butyl ether phase obtained by extracting hydrochloric acid free filtrate is used for drying a solvent through distillation to obtain the crude product of the compound 2 which is directly subjected to nucleophilic reaction with the compound 3, a qualified compound 4 is obtained by a subsequent process purifying treatment (comprising decoloration and salifying), the process operation is simplified, process stability is enhanced, loss of the compound 2 caused by crystallization of methylbenzene or crystallization for multiple times is avoided, and cost of process materials is greatly reduced. Lithium amide and sodium-hydrogen are innovatively substituted by lithium hydrate, safety is higher, cost is lower, lithium hydrate is proper in alkalinity, and a reaction system has few impurity points and is suitable for industrialized amplification production.

Owner:宁波人健化学制药有限公司

Package plastic film

InactiveCN106883567AImprove tensile propertiesImprove water resistanceFlexible coversWrappersPolyamideSalicylic acid

The invention discloses a package plastic film which comprises the following raw materials in parts by weight: 20-35 parts of PC (polycarbonate), 25-40 parts of APET (amorphous polyester), 18-26 parts of PLA (polylactic acid), 4-6 parts of 2-hydroxypropyl-beta-cyclodextrin, 5-11 parts of ASA (acetyl salicylic acid) high glue powder, 7-18 parts of polyamide wax powder, 2-8 parts of 4-dimethylamino isoamyl benzoate, 5-18 parts of trehalose, 5-11 parts of diacetyl tartaric acid ester of mono(di) glycerides, 11-18 parts of tartrate, 11-18 parts of bisphenol A cyanate ester, 4-10 parts of polybutylene terephthalate, 2-5 parts of 3,5-diaminobenzoic acid, 5-11 parts of petroleum coke and 0.1-0.5 part of lithium amide. The package plastic film has good tensile capacity and water resistance since the raw materials are compounded to exert a synergistic effect; the production cost is low; a production technology is simple; the industrial production is facilitated; and the package plastic film can be manufactured into various package bags, and has a higher practical value and a high market popularization value.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Fireproof packaging film

InactiveCN109438827AFlame resistantGuaranteed mechanical propertiesFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention relates to the technical field of films, in particular to a fireproof packaging film. The fireproof packaging film is prepared from components in parts by mass as follows: 35-60 parts ofmetallocene linear low-density polyethylene, 4.5-7.5 parts of oxidized polyethylene wax, 2-6 parts of white master batch, 2-7 parts of polybutylene terephthalate, 3-8 parts of glass fiber, 2-5 partsof 2-hydroxypropyl-beta-cyclodextrin, 2-5 parts of hydroxypropyl acrylate, 4-6 parts of methacrylate, 0.3-0.5 parts of titanium dioxide, 2.1-3.8 parts of calcium carbonate powder, 7-9 parts of bentonite, 3-4 parts of a coupling agent, 4-8 parts of a flame retardant, 1-3 parts of a curing agent, 11-18 parts of tartrate, 1-3 parts of a compatilizer and 0.1-0.5 parts of lithium amide. According to the fireproof packaging film, the plastic film has flame retardance, original mechanical performance of the plastic film is kept, the use safety in building, aerospace and traffic industries and in lifesuch as the packaging material is guaranteed, and adverse conditions are prevented.

Owner:徐州金太阳包装材料有限公司

Lead-free solder soldering flux and preparation method thereof

InactiveCN104985354AIncrease moistureWelding/cutting media/materialsSoldering mediaOrganic acidSurface-active agents

The invention discloses a lead-free solder soldering flux and a preparation method thereof. The lead-free solder soldering flux comprises organic acid, nonionic surface active agents, silicane, fatty acid, lithium amide, trialkyborane, yttrium oxide and rosin. The lead-free solder soldering flux can improve the wettability of Sn-Ag-Cu-system lead-free solder, and is environmentally friendly. In addition, the steps of the preparation method of the soldering flux are simple, and raw materials are easy to obtain.

Owner:WUHU ADER CONVEYOR MACHINERY

LiNH2BH3 synthesis method by taking lithium amide and ammonia borane as raw material

InactiveCN101538015ARapid responseEasy to implementMonoborane/diborane hydridesMaterials preparationSynthesis methods

The invention belongs to the technical field of material preparation, particularly relates to a LiNH2BH3 synthesis method by taking lithium amide and ammonia borane as raw materials. The product can be obtained by liquid reaction and solid reaction, wherein the liquid reaction method includes the following steps: BH3NH3 is dissolved in solvent under anhydrous oxygen-free inert atmosphere, the mixture is added into LiNH2 to react at 10-50 DEG C for 0.1-24 hours, thus obtaining LiNH2BH3 solid, and then the solvent is deprived under vacuum to obtain pure LiNH2BH3; wherein the molar ratio of lithium amide and ammonia borane is 1:1. The solid reaction method includes the following steps: BH3NH3 solid reacts with LiNH2 directly under inert atmosphere at 0-80 DEG C for 0.5-120 minutes, and then impurities and gas are deprived under vacuum to obtain pure LiNH2BH3; wherein the molar ratio of lithium amide and ammonia borane is 1:1. The invention is high in reaction speed, is easy to be realized, and can prepare the product with high purity.

Owner:FUDAN UNIV

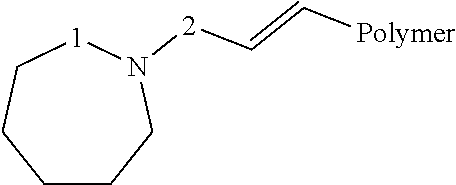

Method for continuous polymerization of modified diene elastomer with lithium amide initiator

ActiveUS20190352433A1Low vinyl contentIncrease contentChemical/physical/physico-chemical processesRolling resistance optimizationElastomerCoupling

A process for the continuous synthesis of a modified diene elastomer comprising at least one silicon atom directly connected to the elastomer chain is provided. The process comprisespolymerization by n reactors r1 to rn, considered to be continuous stirred-tank reactors equipped with an internal stirring system and arranged in series, n varying from 2 to 15. The reactor r1 is fed by an input solution comprising a solvent, one or more monomer(s), an anionic polymerization initiator chosen from lithium amides and a polar agent. The temperature of each reactor varies from 20° C. to 150° C. and is greater than or equal to the temperature of the reactor which immediately precedes it. The living diene elastomer obtained exhibits a polydispersity index varying from 1.1 to 1.7. The process further comprisesmodification of the living diene elastomer obtained in the preceding stage by a functionalization, coupling or star-branching agent.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine

InactiveCN105254670ALow costReduce pollutionGroup 5/15 element organic compoundsAfter treatmentDiethyl methylphosphonate

The invention relates to a preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine. The preparation method comprises the steps of taking (R)-9-(2-hydroxypropyl) adenine as an initial compound and dissolving the (R)-9-(2-hydroxypropyl) adenine into DMF (dimethyl formamide), using lithium amide to participate in a reaction, slowly dropwise adding diethyl p-toluenesulfonyloxymethyl phosphonate, then, performing a heating reaction, and after treatment, using hydrobromic acid to remove ethyl, so as to obtain the (R)-9-[2-(Phosphonomethoxy) propyl] adenine. The initial material used by the preparation method is easy to obtain, safe and stable, the synthetic method is simple to operate, the product yield is high, the purity is high, the pollution to environment is relatively small, and a simple and feasible method is provided for the mass production of the compound, namely the (R)-9-[2-(Phosphonomethoxy) propyl] adenine.

Owner:天津药物研究院药业有限责任公司

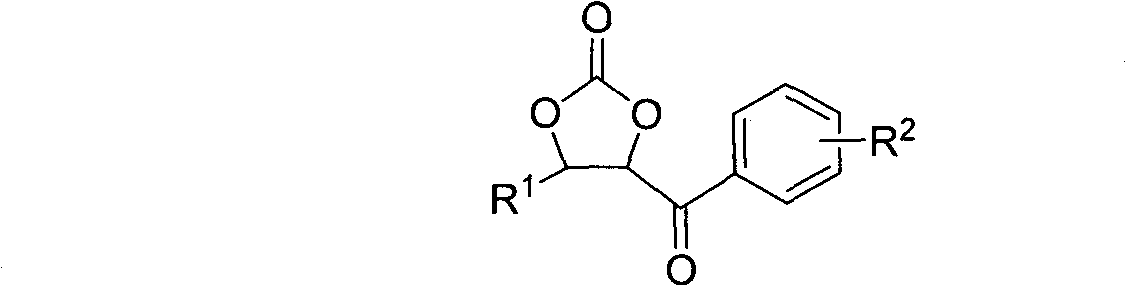

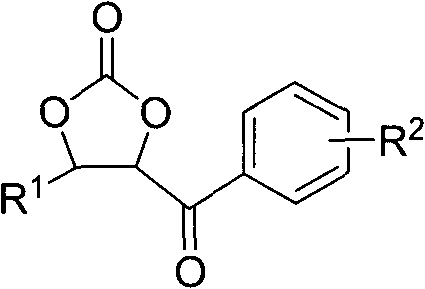

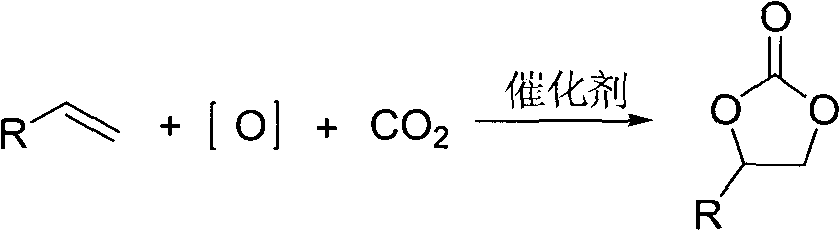

Cyclic carbonate compound and synthesis method thereof

InactiveCN101805324AReaction raw materials are readily availableMild reaction conditionsOrganic chemistryBenzaldehydeSynthesis methods

The invention discloses a cyclic carbonate and a preparation method thereof. The formula of the cyclic carbonate related by the invention is disclosed in the specification. The preparation method comprises the following steps: dissolving benzaldehyde or derivatives thereof and alpha-bromoacetophenone or derivatives thereof in an anhydrous dioxane solution; introducing carbon dioxide gas at the flow rate of 200-300 ml / min under atmospheric pressure at 10-55 DEG C while stirring; dropwisely adding diisopropyl lithium amide into the solution; leading the reaction system completely to react underthe conditions of stable carbon dioxide gas flow; and after the reaction finishes, quenching the reaction with saturated ammonium chloride solution, extracting with ethyl acetate, drying to remove the solvent, and carrying out silicagel column chromatography to obtain the target product.

Owner:LANZHOU UNIVERSITY

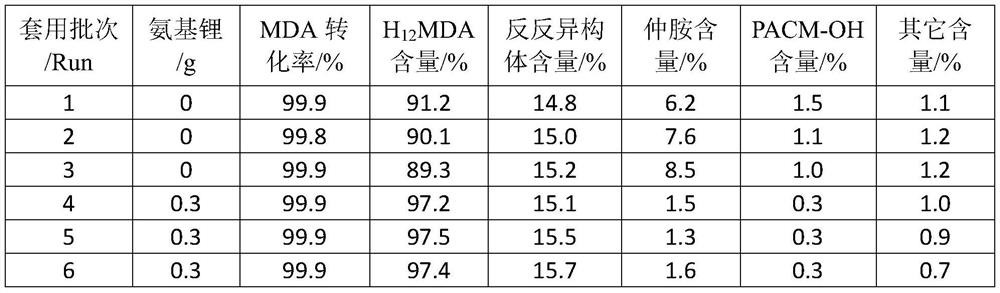

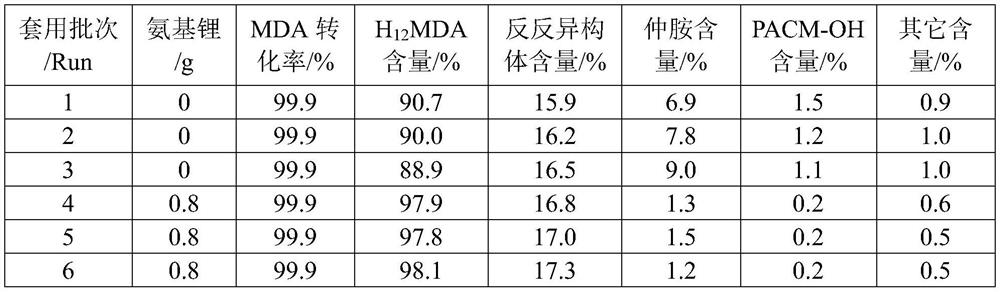

Modified metal supported catalyst, diaminodicyclohexylmethane product and preparation method and application of diaminodicyclohexylmethane product

ActiveCN111804324AImprove responseIncrease contentIsocyanic acid derivatives preparationOrganic compound preparationPtru catalystProcess engineering

The invention relates to a modified metal supported catalyst, a diaminodicyclohexylmethane product, and a preparation method and application of the diaminodicyclohexylmethane product. The modified metal supported catalyst is prepared by modifying a metal supported catalyst by using lithium amide. The modified metal supported catalyst is used for catalyzing a diaminodiphenyl methane hydrogenation method. The content of alicyclic amines in a product can be effectively improved, great increase of secondary amine by-products and PACM-OH is avoided, the proportion of trans-trans-isomers in the product is effectively reduced, the content of secondary amine by-products in each batch of products is greatly reduced to 2% or less, the problem of substantial increase of the filtration separation timeof the catalyst and the product liquid due to increase of the catalyst application frequency is solved, the filtration time is maintained within 40min after 40 batches of catalyst application, and the product yield and the production efficiency are greatly improved.

Owner:WANHUA CHEM GRP CO LTD

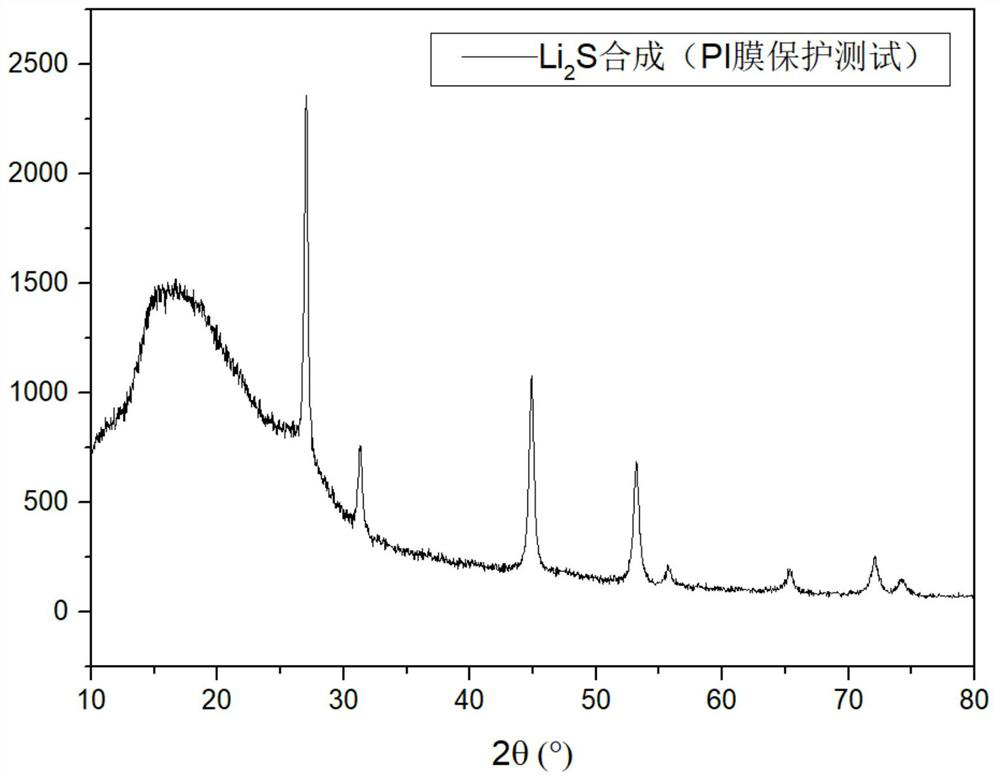

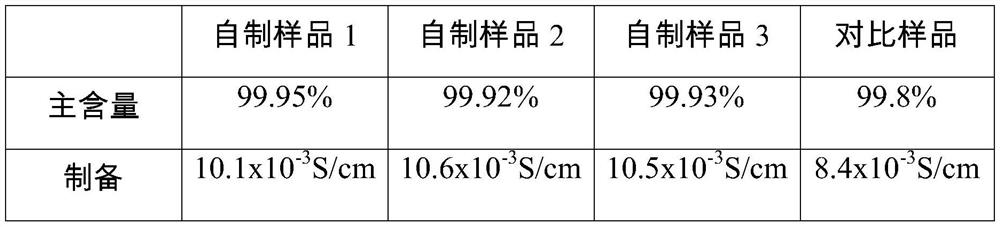

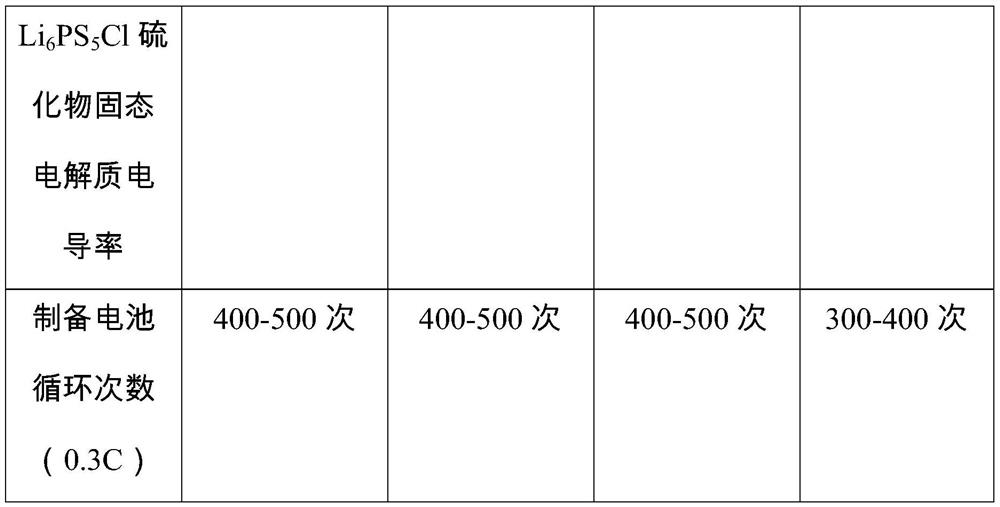

Preparation method and application of high-purity lithium sulfide

ActiveCN113415812ASpeed upImprove electronic conductivityLithium compoundsSecondary cellsMetallic lithiumPhysical chemistry

The invention discloses a preparation method and application of high-purity lithium sulfide. Lithium sulfide is prepared by reacting a lithium amide defective product with hydrogen sulfide. Compared with metal lithium, lithium amide and by-products thereof are easier to react with hydrogen sulfide, so that lithium amide defective products react with hydrogen sulfide, on one hand, the progress of reaction between metal lithium and hydrogen sulfide is accelerated, and on the other hand, a small amount of lithium nitrogen compounds participating in the reaction have higher electron conductivity; and the prepared lithium sulfide is used as a sulfide electrolyte, and the performance of enhancing the electronic conductivity of the sulfide electrolyte can be achieved. Moreover, the economic benefit is also greatly improved by recycling lithium amide defective products.

Owner:高能时代(珠海)新能源科技有限公司

Preparation method of anti-wear agent

InactiveCN110484330AWith surface modificationWith anti-friction and anti-wear effectAdditivesMicrobial oilCalcite

The invention belongs to the technical field of preparation of lubricating materials, and particularly relates to a preparation method of an anti-wear agent. The preparation method comprises the following steps: preparing anti-wear suspension by taking multi-walled carbon nanotubes as a raw material; mixing and heating microbial oil, ethyl palmitate, lithium amide and the like to obtain an esterification product; finally, distilling an antioxidant lubricating grease crude product to obtain antioxidant lubricating grease; subjecting rapeseed oleic acid, azelaic acid and neopentyl glycol which are used as raw materials to esterification to obtain mixed ester; adding the mixed ester into the anti-wear suspension to obtain the anti-wear agent. Aluminum in the anti-wear suspension in the anti-wear agent participates in a local metallurgical reaction to achieve surface modification so that the anti-friction and anti-wear effects are achieved; an aluminum oxide passivation film can be formedto improve extreme pressure lubricating and antioxidant performance. Through the high polarity of the antioxidant lubricating grease, the conversion rate of the calcite crystal form formed by calciumlignosulphonate is improved, and the high-temperature resistance and the self-repairing performance of a lubricant are improved, such that the prepared anti-wear agent has broad application prospects.

Owner:刘群艳

Anticorrosive coating for electric power equipment and preparation method

InactiveCN108912927AGood weather resistanceAccelerated corrosionAnti-corrosive paintsEpoxySodium Bentonite

The invention discloses an anticorrosive coating for electric power equipment and a preparation method thereof, and relates to the coating field, the anticorrosive coating includes the flowing raw materials by weight: 20-26 parts of modified acrylate, 12-18 parts of epoxy resin, 3-7 parts of N-methyl pyrrolidone, 3-7 parts of lauryl alcohol polyoxyethylene ether, 2-6 parts of mica powder, 1.5-2.8parts of zirconium acetate, 3-7 parts of mullite powder, 2-6 parts of lithium bentonite, 2-7 parts of nano-titanium dioxide, 0.8-1.6 parts of lithium amide, 1.2-3.4 parts of diamond, 1-3 parts of molybdenum trioxide, 1.5-3 parts of nano-silicon carbide, 3-6 parts of nano-zinc oxide, 3-6 parts of glass fiber and the like. The coatings has good weatherability and corrosion resistance through the synergistic action of the raw materials, and through compound effect of the diamond and the nano-silicon carbide and other raw materials, the scratch resistance between coatings is enhanced.

Owner:合肥市闵葵电力工程有限公司

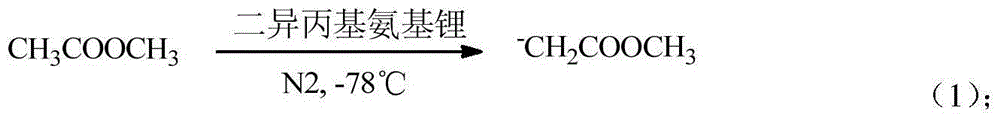

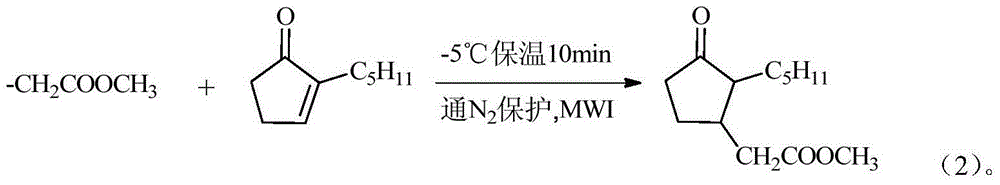

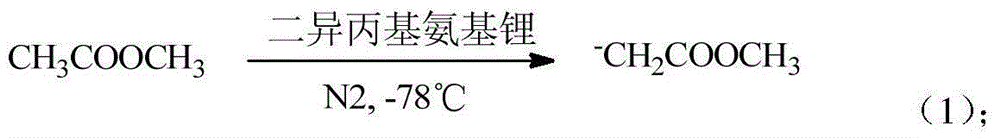

Synthetic method for MDJ (Methyl Dihydrojasmonate)

InactiveCN104628565AReduce pollutionThe reaction route is simpleOrganic compound preparationCarboxylic acid esters preparationMicrowaveProton

The invention discloses a synthetic method for MDJ (Methyl Dihydrojasmonate), which comprises the following steps of removing protons from methyl acetate under the action of an alkaline reagent diisopropyl lithium amide to obtain active methylene ions, and carrying out Michael addition reaction on the active methylene ions and 2-amyl cyclopentenone under the action of microwaves to obtain the MDJ. The synthetic method provided by the invention has the advantages that the process path is simple, the raw materials for the reaction materials are cheap, and the pollution to the equipment and the environment is less, and meanwhile the yield of the product can reach 45%.

Owner:ANHUI UNIV OF SCI & TECH

Synthesis method of lithium amide

ActiveCN112079339AImprove operational safetyLow costNitrogen compoundsLithium hydroxideMaterial synthesis

The invention relates to the field of material synthesis, in particular to a synthesis method of lithium amide. Directed at the existing problems of few lithium amide synthesis method, high process energy consumption and the like, the invention discloses a synthesis method of lithium amide. The method comprises the following steps of: taking lithium hydroxide, calcium hydride and ammonia gas as the raw materials, performing ball milling in vacuum, then performing ball milling in an ammonia gas atmosphere, performing liquid ammonia separation on a product after the reaction is finished, and drying a liquid substance, thereby obtaining the lithium amide. The synthesis method of lithium amide provided by the invention is simple in process, low in cost and high in safety.

Owner:ZHEJIANG UNIV OF TECH

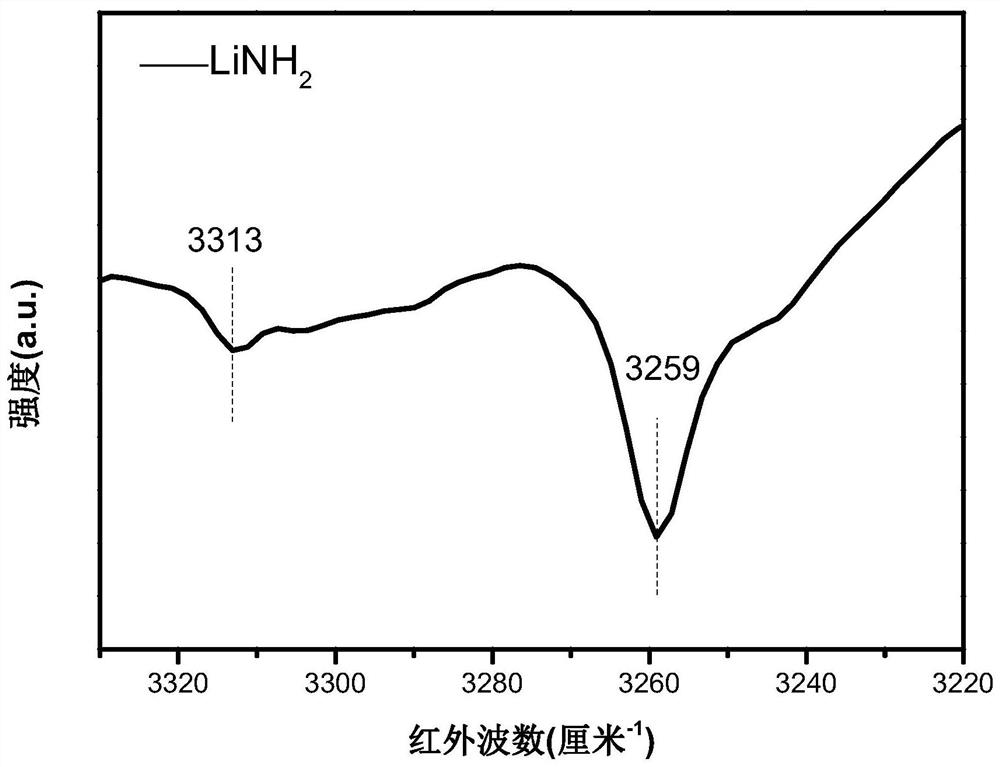

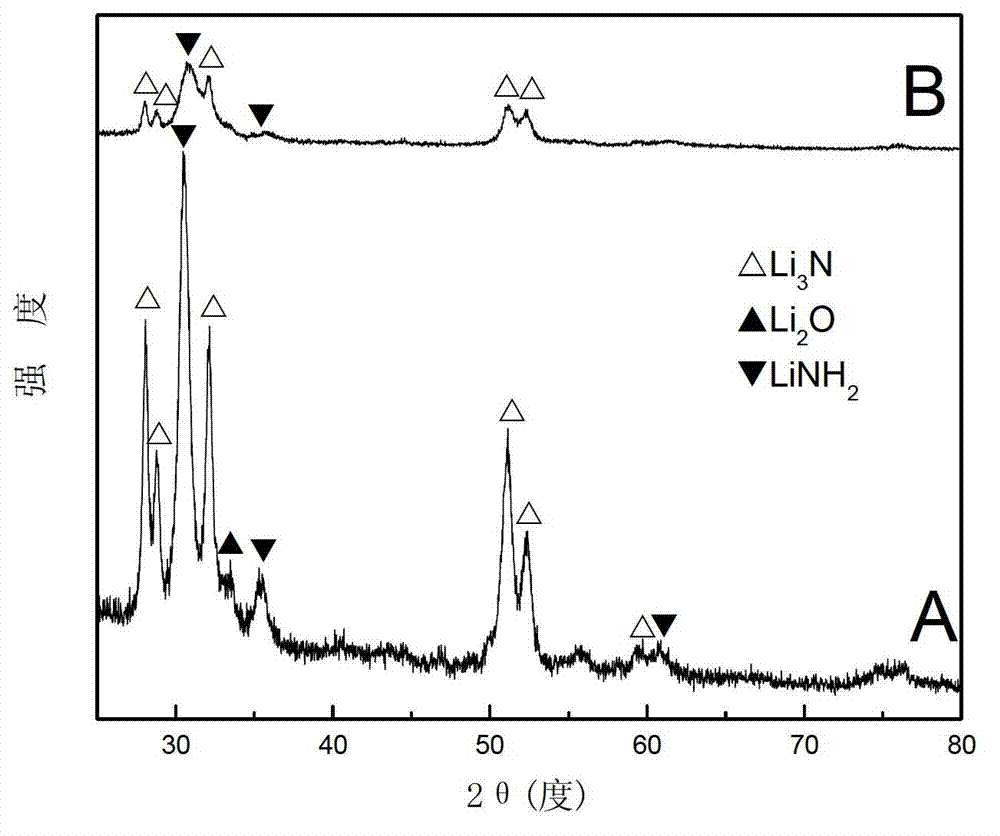

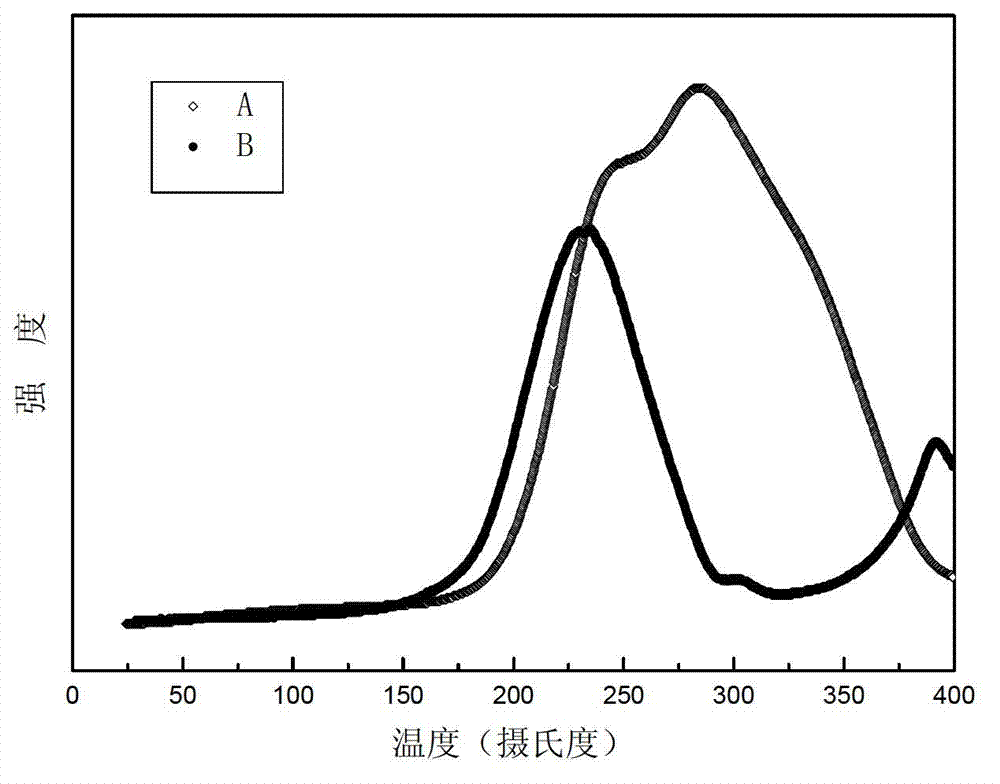

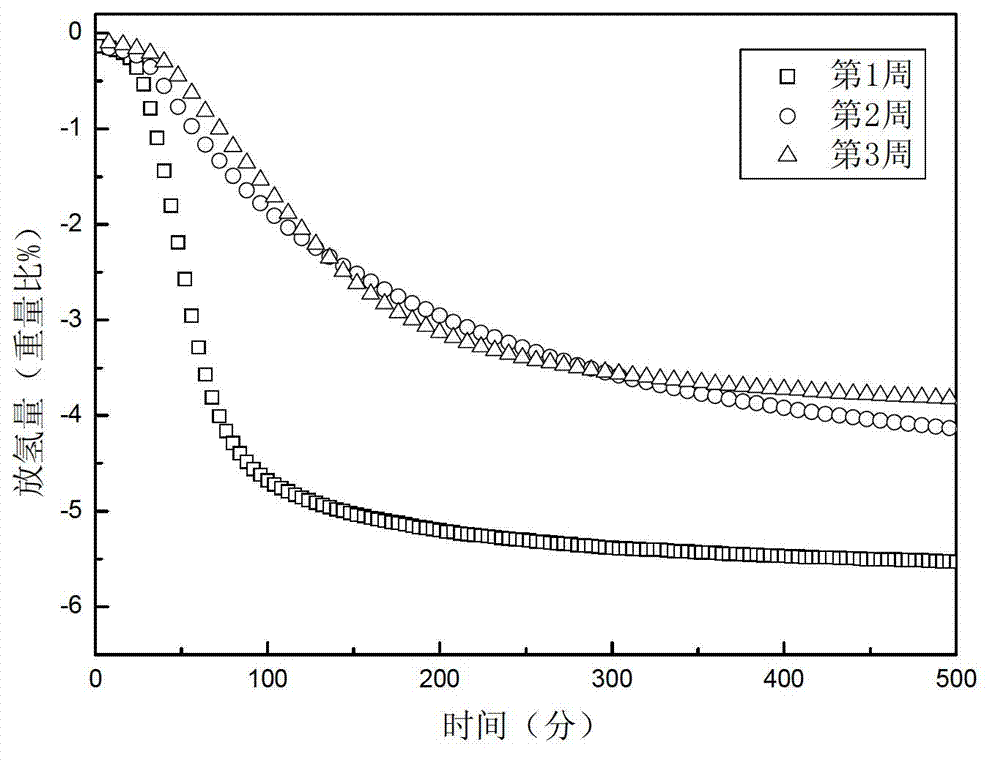

Light gas-solid hydrogen storage material and preparation method thereof

InactiveCN102774809AFast hydrogen releaseCyclic stabilityHydrogen productionCyclic processTriphenyl phosphite

The invention relates to a light gas-solid hydrogen storage material. The light gas-solid hydrogen storage material consists of a Li-N-H composite hydrogen storage material and triphenyl phosphite, wherein the Li-N-H composite hydrogen storage material is an active material, and consists of lithium nitride (Li3N) and lithium amide (LiNH2), and triphenyl phosphate is a non-active material. The preparation method comprises the following steps of: mixing the Li3N and the LiNH2 with equal molar ratio under the argon shield, adding triphenyl phosphate, and carrying out ball milling for 2-50h with the ratio of grinding media to material being (10-60):1 and the rotating speed of 100-450 turns / min. The invention has the advantages that the phenomena of wall attachment and agglomeration of powder in the ball milling process are eliminated due to the addition of triphenyl phosphite, the hydrogen discharge temperature of the Li-N-H material is lowered, the Li-N-H material is effectively prevented from being sintered in the cyclic process of absorbing and discharging hydrogen, the hydrogen discharge dynamic performance and cyclic stability are improved, and hydrogen can be stored and transported safely and efficiently. The preparation method is simple and easy to implement.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine](https://images-eureka.patsnap.com/patent_img/a420d299-45fc-4fb2-a07f-e5b66003a48f/DEST_PATH_151214094402.PNG)

![Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine](https://images-eureka.patsnap.com/patent_img/a420d299-45fc-4fb2-a07f-e5b66003a48f/DEST_PATH_151214094441.PNG)

![Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine](https://images-eureka.patsnap.com/patent_img/a420d299-45fc-4fb2-a07f-e5b66003a48f/116369DEST_PATH_IMAGE005.PNG)