Light gas-solid hydrogen storage material and preparation method thereof

A hydrogen storage material, gas-solid technology, applied in the production of hydrogen and other directions, can solve problems such as insignificant effects, and achieve the effects of eliminating powder agglomeration on the wall, fast hydrogen release, and reducing hydrogen release temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of light gas-solid hydrogen storage material, the steps are as follows:

[0021] 1) Under the protection of argon atmosphere, the equimolar ratio of Li 3 N and LiNH 2 Put it in a ball mill jar, mix evenly and add TPP with a mass percentage of 20%;

[0022] 2) Under the protection of argon atmosphere, ball milling for 10 hours under the conditions of ball-to-material ratio of 60:1 and rotation speed of 400 rpm, the composition of Li 3 N-LiNH 2 Lightweight gas-solid hydrogen storage material with +20wt.%TPP.

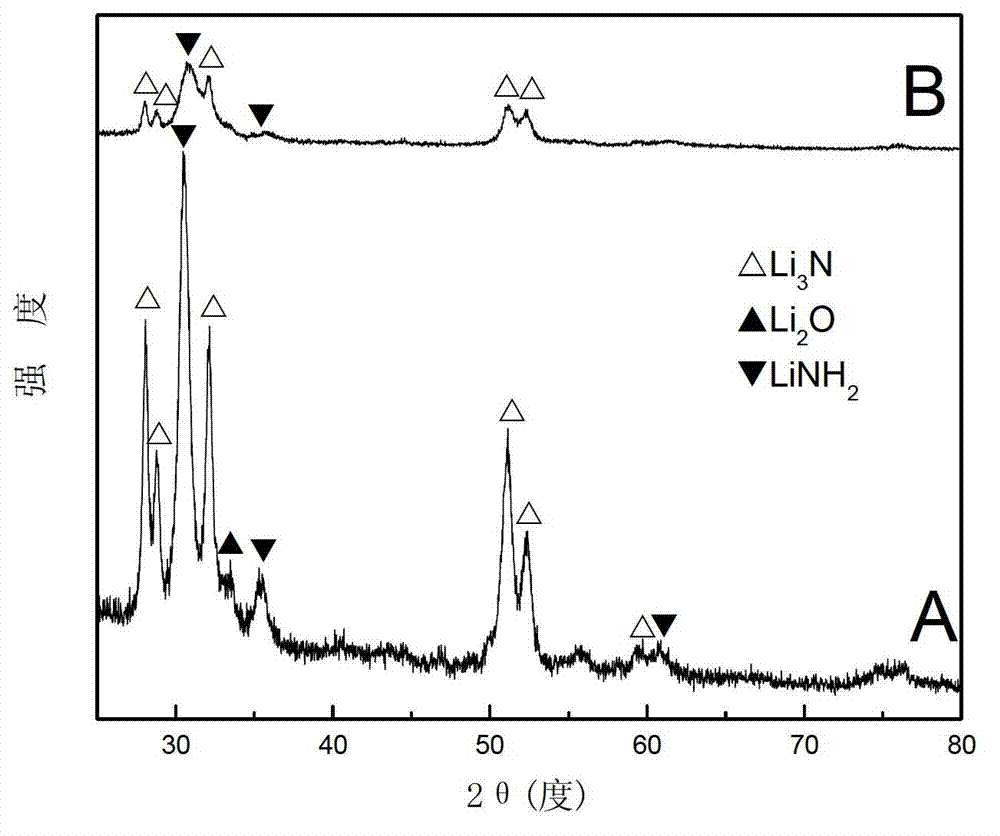

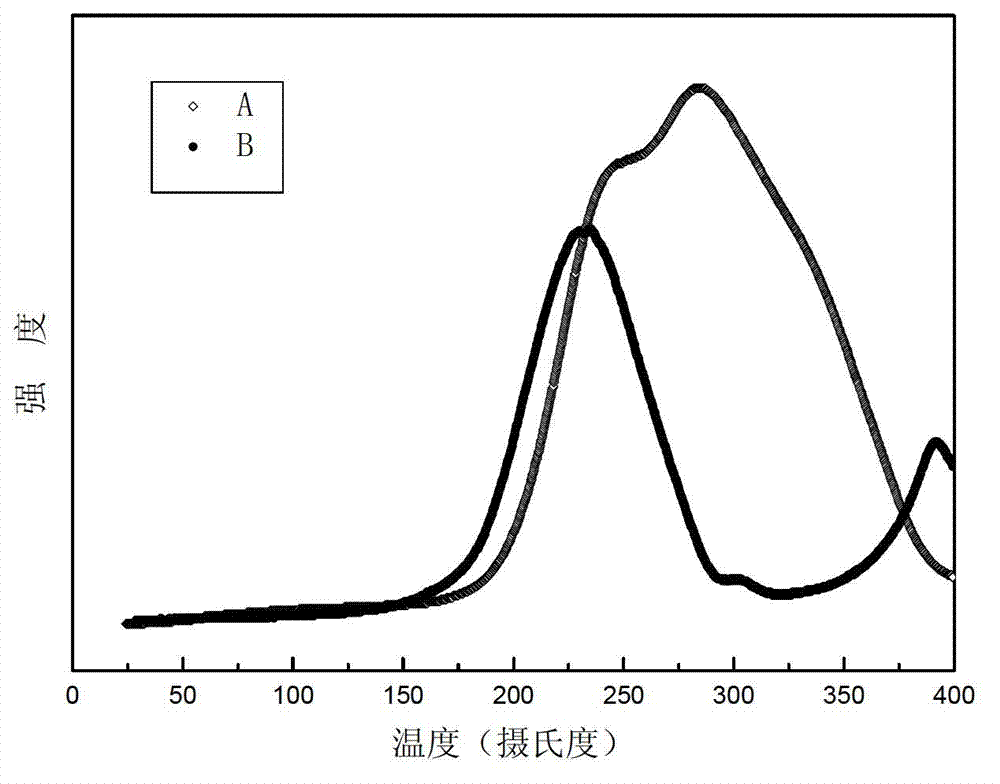

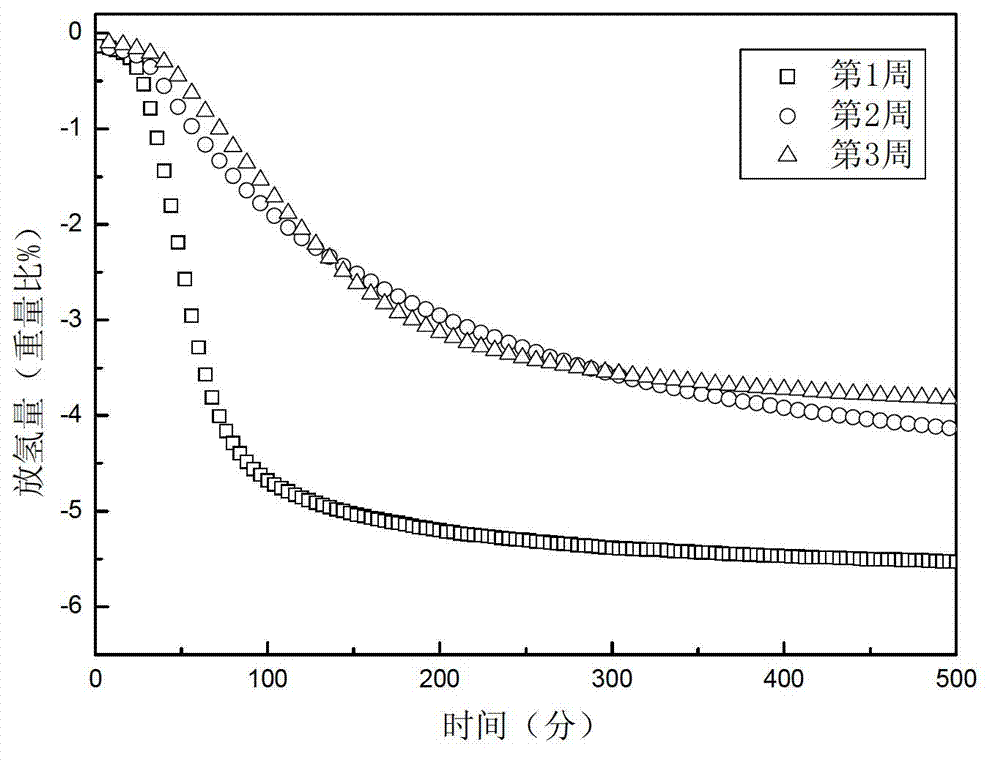

[0023] figure 1 Li before and after adding 20wt.%TPP 3 N-LiNH 2 X-ray diffraction (XRD) pattern of the sample after ball milling for 10 h. It can be seen from the figure that the diffraction peak positions before and after the addition of TPP are the same, both determined by Li 3 N and LiNH 2 phase composition, no other phases are formed. However, the diffraction peaks after adding TPP are more broadened, indicating that TPP has not be...

Embodiment 2

[0029] A preparation method of light gas-solid hydrogen storage material, the steps are as follows:

[0030] 1) Under the protection of argon atmosphere, the equimolar ratio of Li 3 N and LiNH 2 Put it in a ball mill jar, mix evenly and add TPP with a mass percentage of 25%;

[0031] 2) Under the protection of argon atmosphere, ball milling for 40h under the conditions of ball-to-material ratio of 30:1 and rotation speed of 200 rpm, the composition of Li 3 N-LiNH 2 Lightweight gas-solid hydrogen storage material with +25wt.% TPP.

[0032] The obtained sample carries out XRD test, and its result is consistent with figure 1 resemblance. Li 3 N-LiNH 2 +25wt.%TPP material only consists of Li 3 N and LiNH 2 phase composition, and the diffraction peaks are wider, indicating that TPP acts as a lubricant and dispersant, making the sample ball milled more fully and uniformly, and the crystal grains of the sample become smaller. TPD curve shape and embodiment 1 figure 2 rese...

Embodiment 3

[0034] A preparation method of light gas-solid hydrogen storage material, the steps are as follows:

[0035] 1) Under the protection of argon atmosphere, the equimolar ratio of Li 3 N and LiNH 2 Put it in a ball mill jar, mix evenly and add TPP with a mass percentage of 5%;

[0036] 2) Under the protection of argon atmosphere, ball milling for 50 hours under the conditions of ball-material ratio of 10:1 and rotation speed of 450 rpm, the composition of Li 3 N-LiNH 2 Lightweight gas-solid hydrogen storage material with +5wt.%TPP.

[0037] The obtained sample carries out XRD test, and its result is consistent with figure 1 resemblance. Li 3 N-LiNH 2 +5wt.%TPP material only consists of Li 3 N and LiNH 2 phase composition, and the diffraction peaks are wider, indicating that TPP acts as a lubricant and dispersant, making the sample ball milled more fully and uniformly, and the crystal grains of the sample become smaller. TPD curve shape and embodiment 1 figure 2 resemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com