Patents

Literature

60 results about "Diethyl methylphosphonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of C-14 enol ether

InactiveCN102180774AThe reaction route is simpleRaw materials are easy to obtainEther preparationDimethyl methylphosphonateDiethyl methylphosphonate

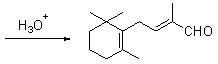

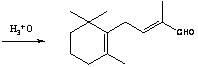

The invention relates to a preparation method of C-14 enol ether. The C-14 enol ether is an intermediate of vitamin A, and the chemical name of the C-14 enol ether is 1-methoxy-2-methyl-4-(2,6,6-trimehtyl-1-cyclohexene-1-ly)-1,3-butadiene. The preparation method comprises the step of carrying out Wittig-Horner condensation reaction on beta-irisone as shown in a formula 4 and diethyl methylphosphonate as shown in a formula 8 at the temperature of minus 40-30 DEG C in an ether solvent or dipolar aprotic solvent in the presence of alkali so as to prepare the C-14 enol ether as shown in a formula7. According to the preparation method, reaction route is simple, and raw materials are simple and available.

Owner:SHAOXING UNIVERSITY

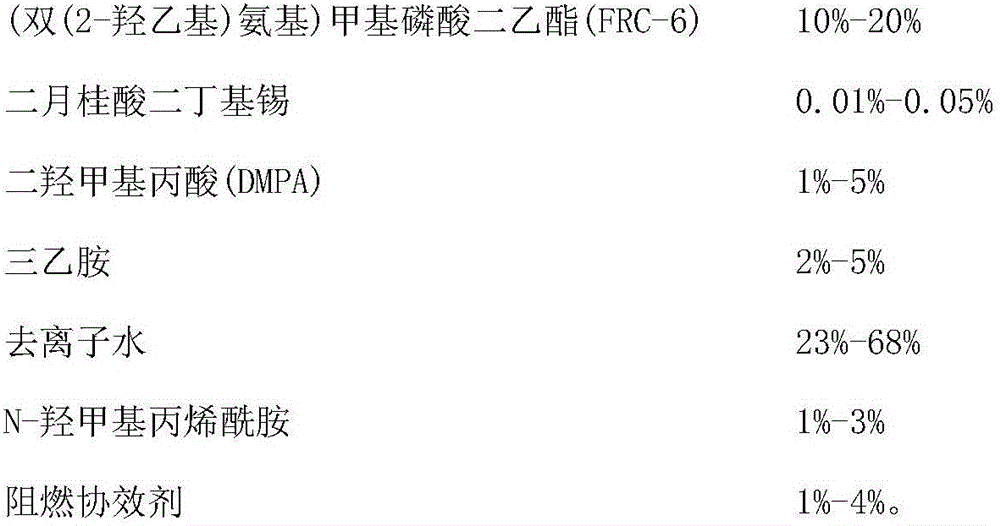

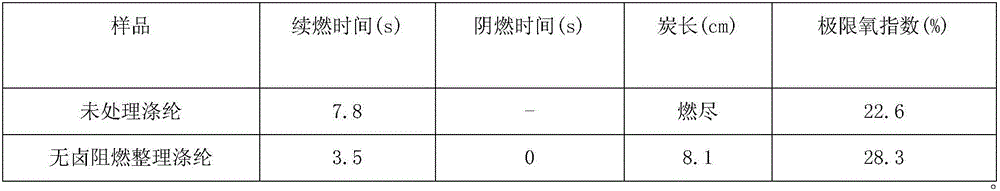

Halogen-free flame-retardant textile finishing agent as well as preparation method and application thereof

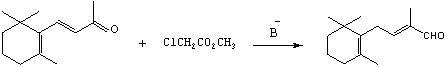

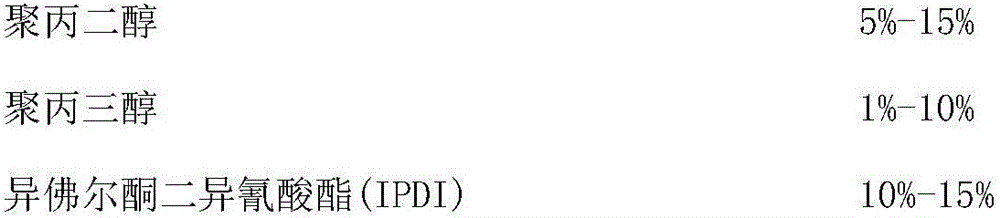

The invention discloses a halogen-free flame-retardant textile finishing agent as well as a preparation method and application thereof. The halogen-free flame-retardant textile finishing agent comprises the following components in percentage by weight: 5-15% of polypropylene glycol, 1-10% of polyglycerol, 10-15% of isophorone diisocyanate (IPDI), 10-20% of (di(2-ethoxyl) amino) diethyl methylphosphonate (FRC-6), 0.01-0.05% of dibutyltin dilaurate, 1-5% of dimethylolpropionic acid (DMPA), 2-5% of triethylamine, 23-68% of deionized water, 1-3% of N-hydroxymethyl acrylamide and 1-4% of a flame-retardant synergist. According to the halogen-free flame-retardant textile finishing agent, in waterborne polyurethane macromolecules, diethyl methylphosphonate is introduced into a polyurethane chain by using a copolymerization method, so that diethyl methylphosphonate can serve as a structural constituent part of a final product, and the halogen-free flame-retardant textile finishing agent is good in durability and flame retardancy; and in addition, due to adoption of the cross-linking agents, namely, N-hydroxymethyl acrylamide and the flame-retardant synergist, in synthesized halogen-free flame-retardant waterborne polyurethane, the halogen-free flame-retardant textile finishing agent is relatively good in durability and good in synergetic flame-retardant effect.

Owner:中国纺织科学研究院江南分院

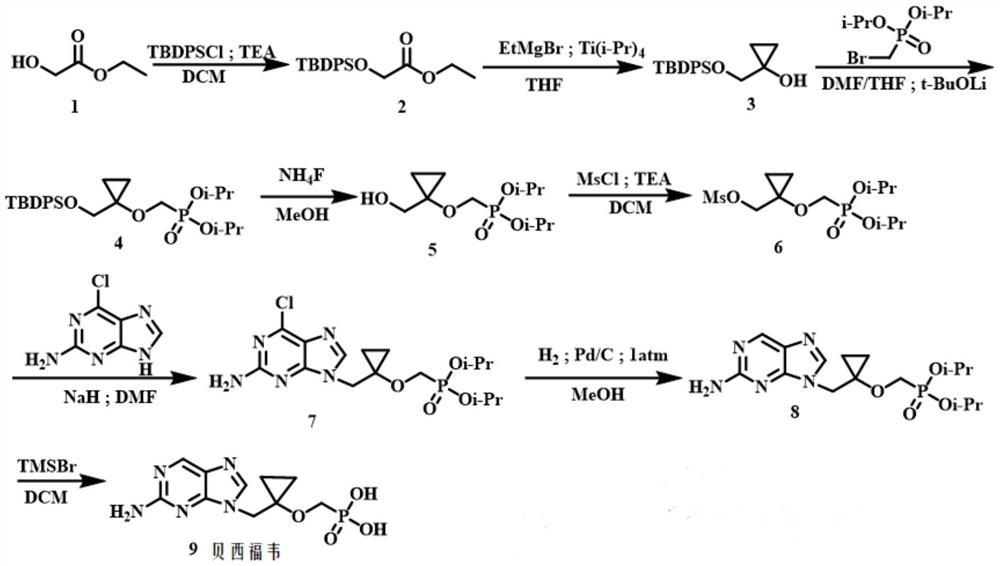

Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate

ActiveUS20080004449A1Simple processImprove production yieldAntipyreticGroup 5/15 element organic compoundsArylLeaving group

This application discloses a novel process for the preparation of phosphonate esters useful as intermediates in the preparation of himbacine analogs, themselves useful as thrombin receptor antagonists. The chemistry taught herein can be exemplified by the following scheme: wherein R9 is selected from alkyl, aryl heteroaryl and arylalkyl groups having 1 to 10 carbon atoms, and R11 is selected independently for each occurrence from alkyl, aryl heteroaryl and arylalkyl groups having 1 to 10 carbon atoms and hydrogen, X2 is Cl, Br, or I; X3 is selected from Cl and Br; and PdLn is a supported palladium metal catalyst or a soluble heterogeneous palladium catalyst. The L-derivatizing reagent is a moiety which converts the alcohol functional group of compound 137D to any leaving group which can be displaced by a triorgano-phosphite phosphonating agent.

Owner:XSPIRE PHARMA LLC

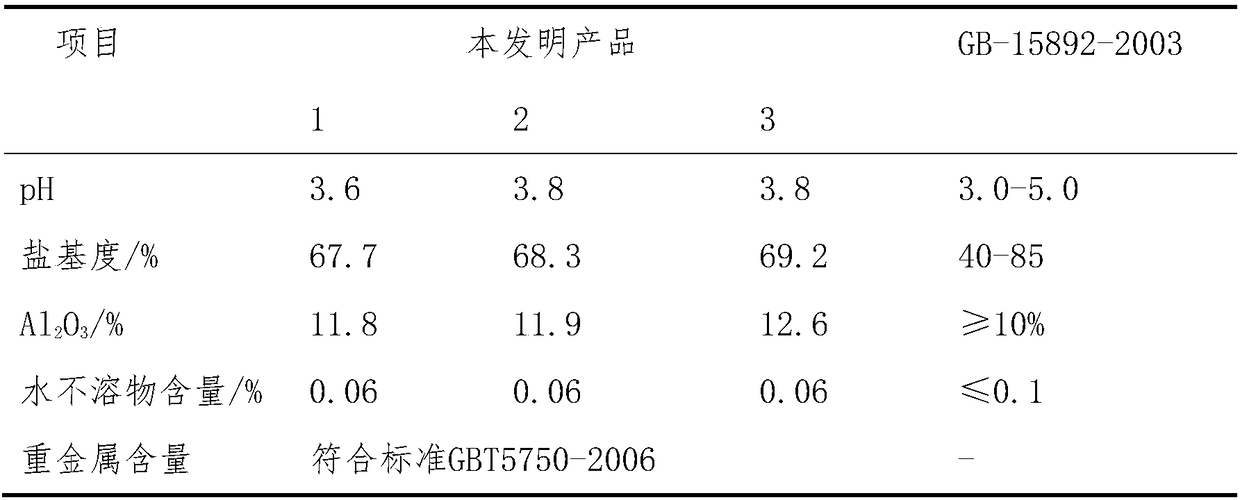

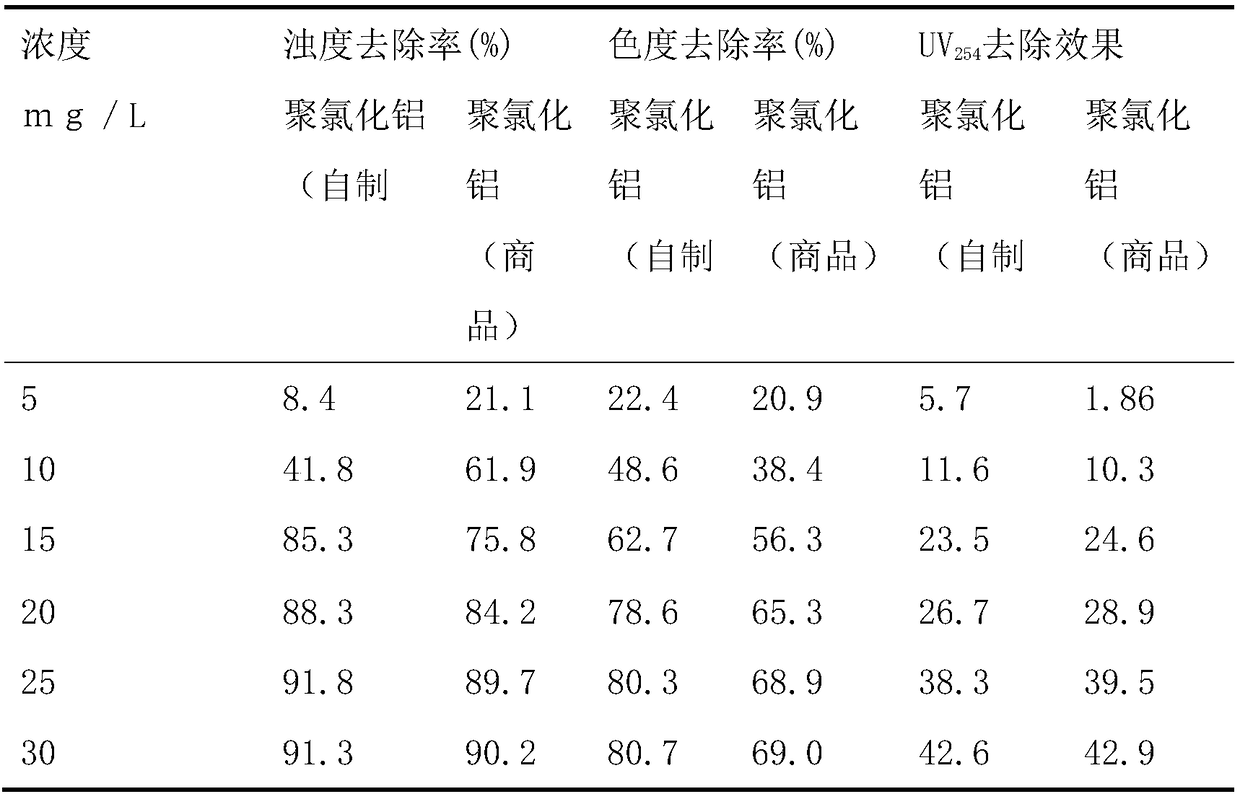

Method for producing poly aluminum chloride by using byproduct of diethyl methylphosphonate production

ActiveCN108238621ASimple processLow costAluminium chloridesAlkali metal chloridesDimethyl methylphosphonateAluminium chlorohydrate

The invention relates to a method for producing poly aluminum chloride by using a byproduct of diethyl methylphosphonate production. The method comprises the following steps: (1) slowly adding a byproduct sodium tetrachloraluminate, rich in sodium tetrachloraluminate and obtained in a production process of diethyl methylphosphonate, into a dissolving kettle for dissolution, and collecting the solution; (2) adding ferric trichloride and hydrochloric acid; (3) sequentially adding aluminum hydroxide and calcium metaaluminate for polymerization reaction; (4) controlling the temperature to be 100 DEG C, and performing thermal reaction for 75min; and (5) cooling, and performing solid-liquid separation, wherein the filtrate is the product of the invention. The method disclosed by the invention has the advantages of simple process, high efficiency, low consumption, energy conservation, greenness and environmental friendliness and low cost.

Owner:洪湖源泰科技有限公司

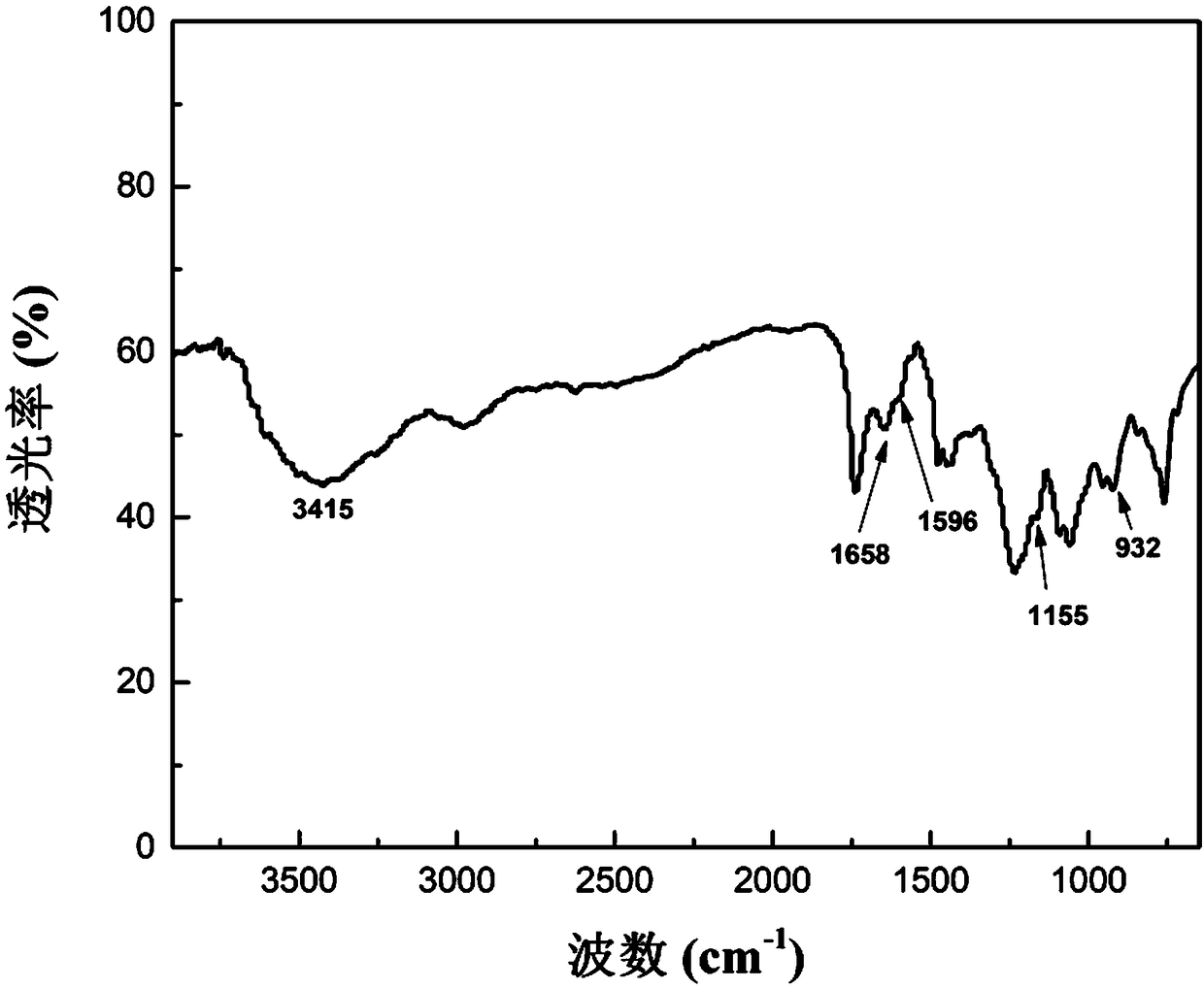

A kind of preparation method of n,n-bis(2-hydroxyethyl)aminomethylphosphonic acid diethyl ester

ActiveCN102276645AReduce pollutionReduce manufacturing costGroup 5/15 element organic compoundsLiquid productDepolymerization

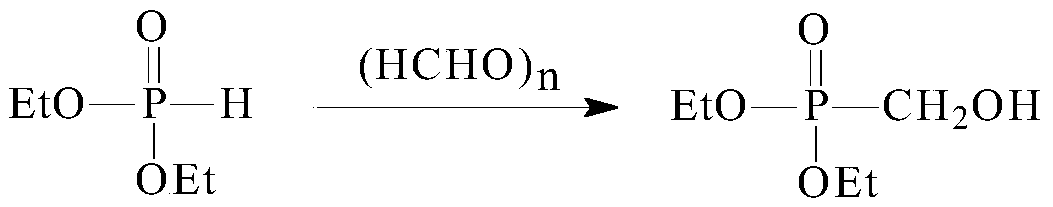

The invention provides a preparation method of diethyl N,N-bis(2- hydroxyethyl) aminomethylphosphonate, comprising the following steps: (1) carrying out depolymerization on paraformaldehyde; (2) carrying out ring formation on formaldehyde and diethanol amine to prepare 3-(2- hydroxyethyl)-1,3-oxazolidine; (3) reacting 3-(2- hydroxyethyl)-1,3-oxazolidine with diethyl phosphite in the presence of anhydrous Lewis acid catalysts; and (4) filtering and recovering the catalysts to obtain a yellow transparent liquid product. The overall yield of the whole process reaches more than 99 %, and the content of diethyl N,N-bis(2- hydroxyethyl) aminomethylphosphonate in the product is 94 %-96 %. The preparation method disclosed in the invention is simple and efficient, has the advantages of high product yield, high content of effective components in the product, reduction of temperature in dehydration process, shortening of time, and low energy consumption, reduces the water content of the final product to 0.1-0.2 %, and reduces the dosage of the catalysts by 20-50%. The preparation method is suitable for large-scale industrial production.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

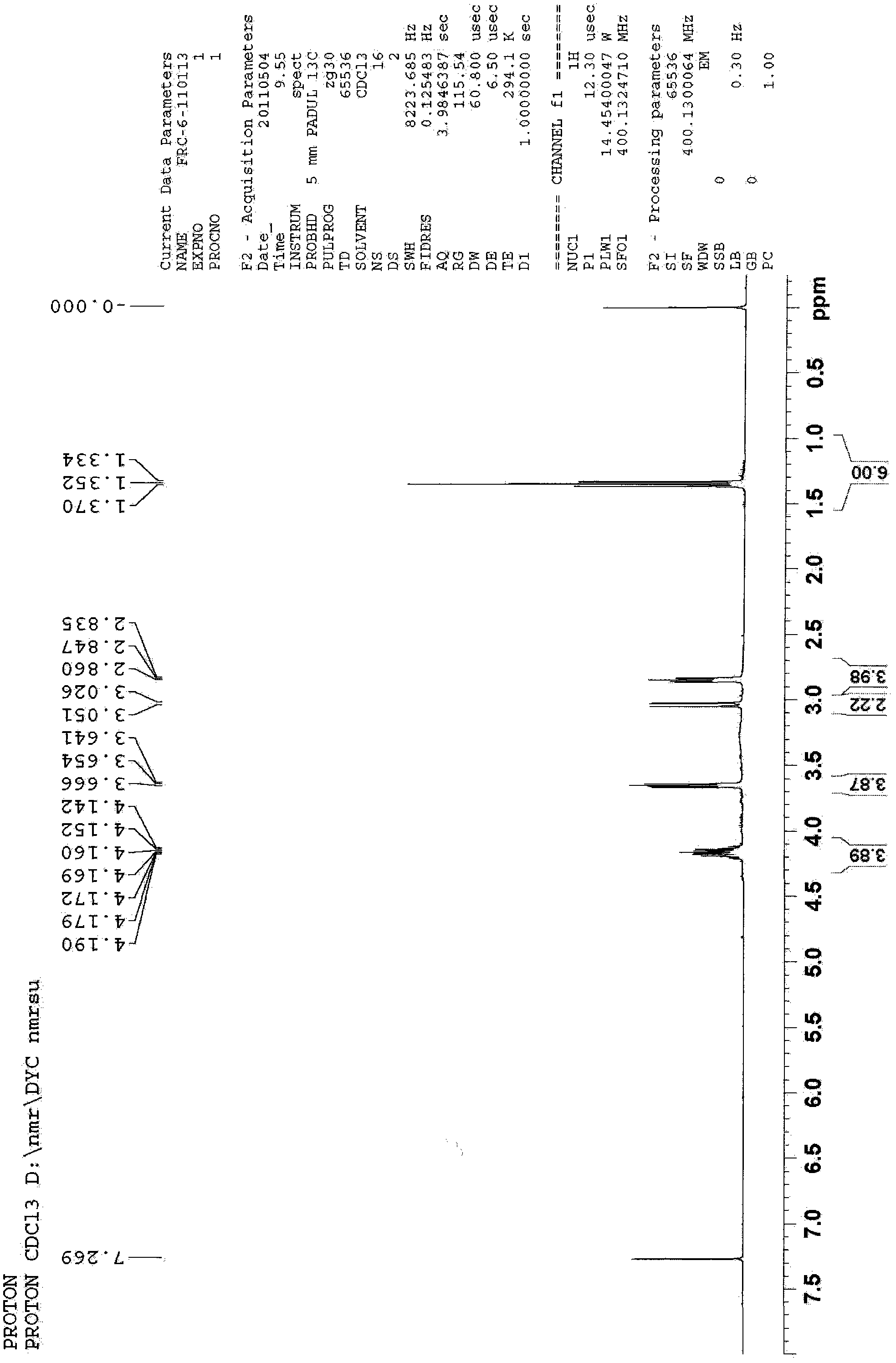

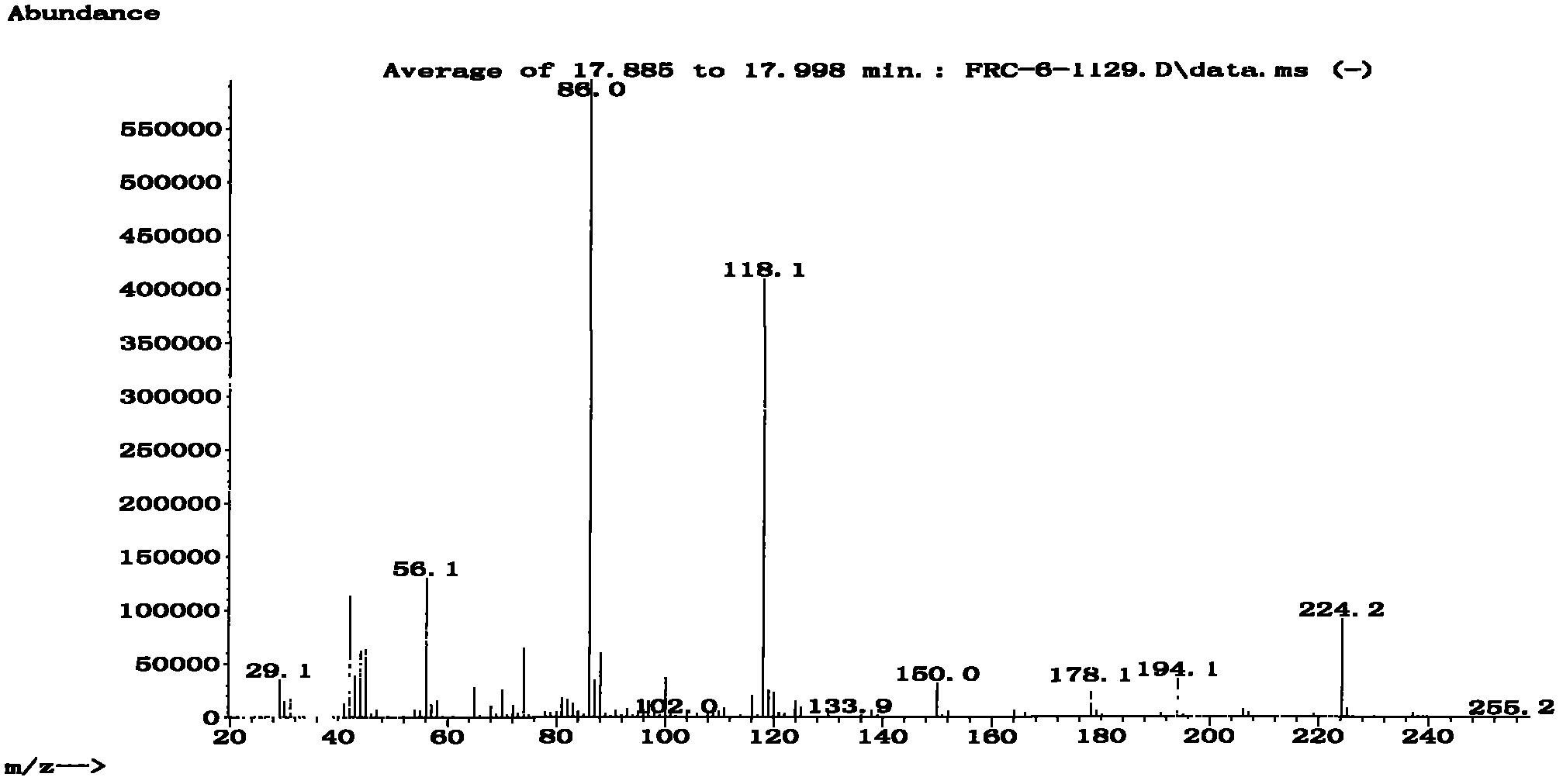

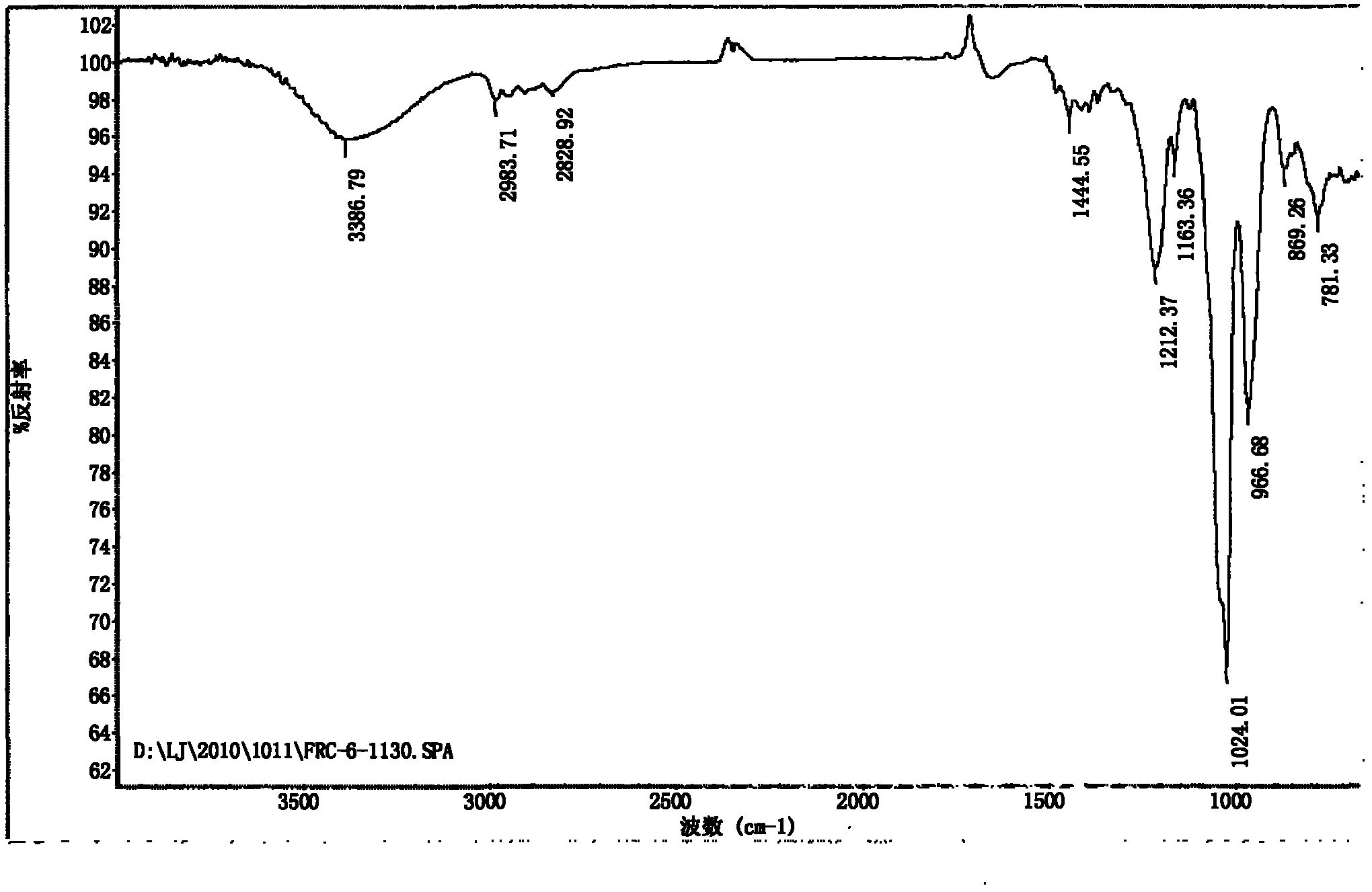

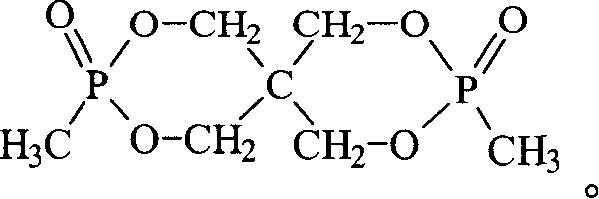

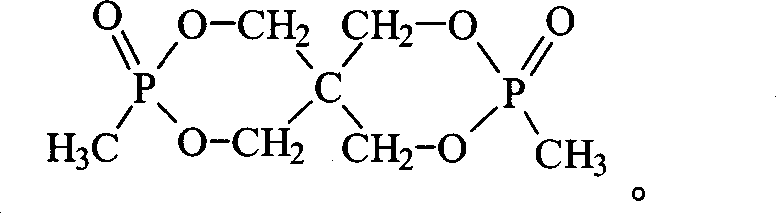

Dicyclic phosphonate fire retardant and its synthesis

InactiveCN1888013AHigh phosphorus contentImprove thermal stabilityGroup 5/15 element organic compoundsDimethyl methylphosphonatePtru catalyst

The present invention discloses one kind of dicyclic phosphonate fire retardant in the structure as shown. Its synthesis process includes the following steps: 1. setting pentaerythritol and dimethyl methyl phosphonate or diethyl methyl phosphonate in the molar ratio of 1 to 2-3 in some connector, adding solvent and catalyst, and stirring at 150-190 deg.c under the protection of inert gas for 3-28 hr; and 2. slowly raising the temperature to 150-180 deg.c, maintaining for 6-26 hr, eliminating excessive dimethyl methyl phosphonate or diethyl methyl phosphonate under vacuum, and lowering the temperature to room temperature to obtain the fire retardant. The synthesis process is simple, efficient, no halogen and environment friendly, and the fire retardant has high phosphorus content, is solid at normal temperature, heat stable and compatible with polymer, and may be used in different fire retardant systems.

Owner:DONGHUA UNIV

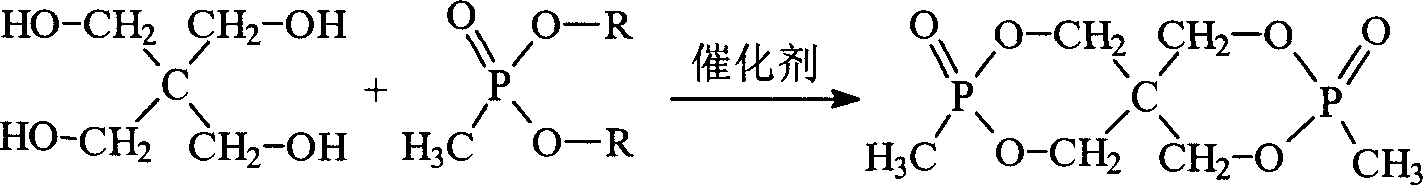

Synthetic method of diethyl methyl-phosphonite and glufosinate-ammonium

ActiveCN103319529AReduce manufacturing costReaction raw materials are cheap and easy to obtainGroup 5/15 element organic compoundsPhosphorous acidOrganic solvent

The invention discloses a synthetic method of diethyl methyl-phosphonite and glufosinate-ammonium. The synthetic method comprises the following steps: carrying out a reaction between diethyl phosphite and chloromethane gas in the presence of an acid binding agent to prepare diethyl methylphosphonite, and filtering after reaction, wherein the generated diethyl methylphosphonite exists in a filtrate; dropwisely adding an organic solvent, in which a reducing agent is dissolved, into the filtrate so as to reduce diethyl methylphosphonite into diethyl methyl-phosphonite, distilling a reaction solution after the reaction so as to obtain diethyl methyl-phosphonite, and preparing glufosinate-ammonium by using diethyl methyl-phosphonite as an intermediate. According to the invention, diethyl phosphite is used as a raw material; reaction raw materials are cheap and easily available; the reaction process is simple and easy to operate and is green and environmentally friendly; atom utilization rate is high; quality of the obtained product is good; yield is high; a new idea is provided for the synthesis of glufosinate-ammonium; preparation cost of glufosinate-ammonium is also reduced; and the synthetic method has wide application value.

Owner:SHANDONG WEIFANG RAINBOW CHEM

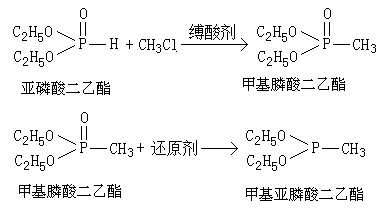

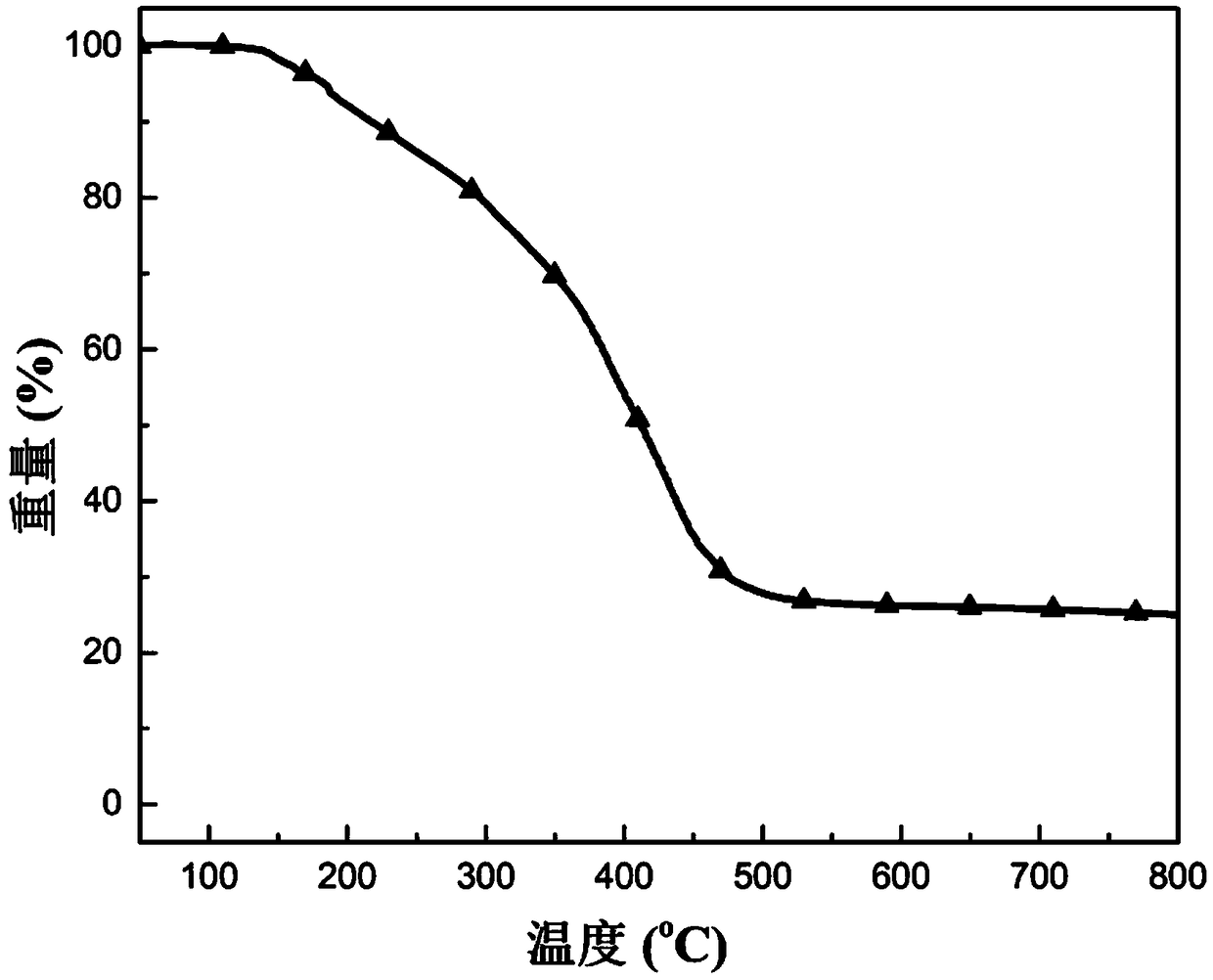

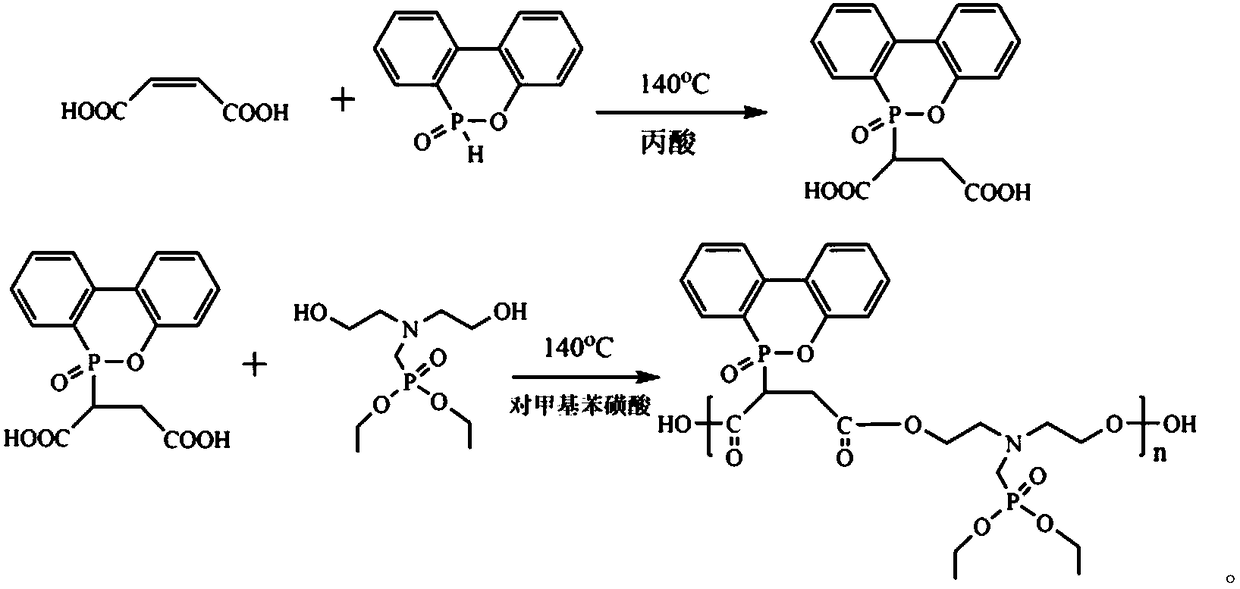

Preparation method of reactive nitrogen-phosphorus flame retardant for aqueous polyurethane

ActiveCN109180924AStable structureImprove flame retardant performanceDiethyl methylphosphonateCarboxylic acid

The invention relates to a preparation method of a reactive nitrogen-phosphorus flame retardant for aqueous polyurethane. The preparation method comprises: (1) adding 9,10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide, a dicarboxylic acid with a double bond or an anhydride with a double bond, and a solvent A to a reaction container, uniformly mixing, carrying out an addition reaction for 12-24 hat a temperature of 140-180 DEG C under stirring, and carrying out vacuum drying on the mixture obtained by the reaction after achieving the reaction time to obtain a phosphorus-containing derivative;and (2) adding the phosphorus-containing derivative obtained in the step (1), diethyl bis(2-hydroxyethyl)aminomethylphosphonate, a water-carrying agent B and a catalyst C to a reaction container, mixing uniformly, carrying out an esterification reaction for 12-24 h at a temperature of 140-160 DEG C under stirring, and carrying out vacuum drying on the mixture obtained by the reaction after achieving the reaction time to obtain the reactive nitrogen-phosphorus flame retardant. According to the present invention, the reactive nitrogen-phosphorus flame retardant for aqueous polyurethane is prepared by the above method.

Owner:SICHUAN UNIV

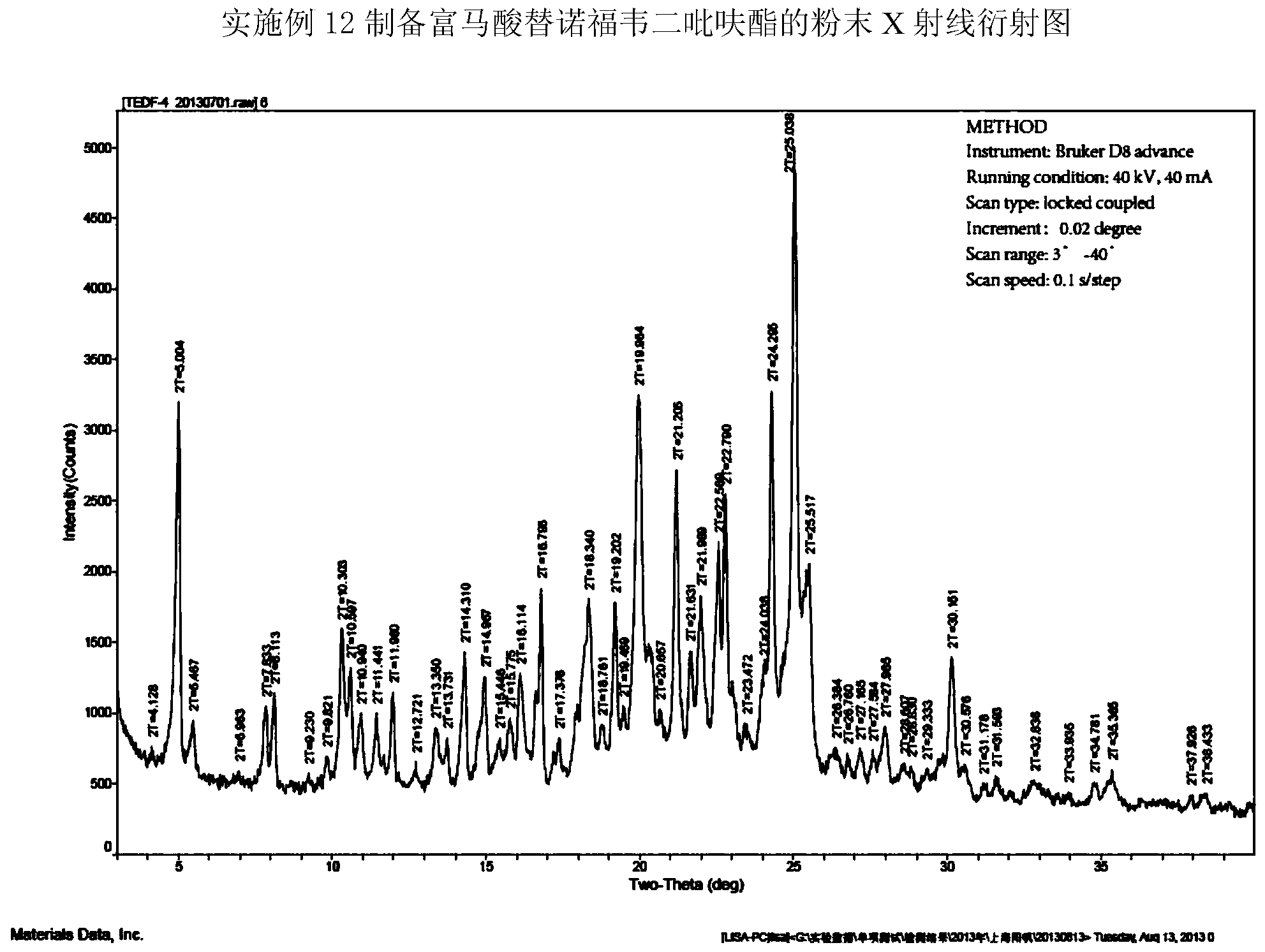

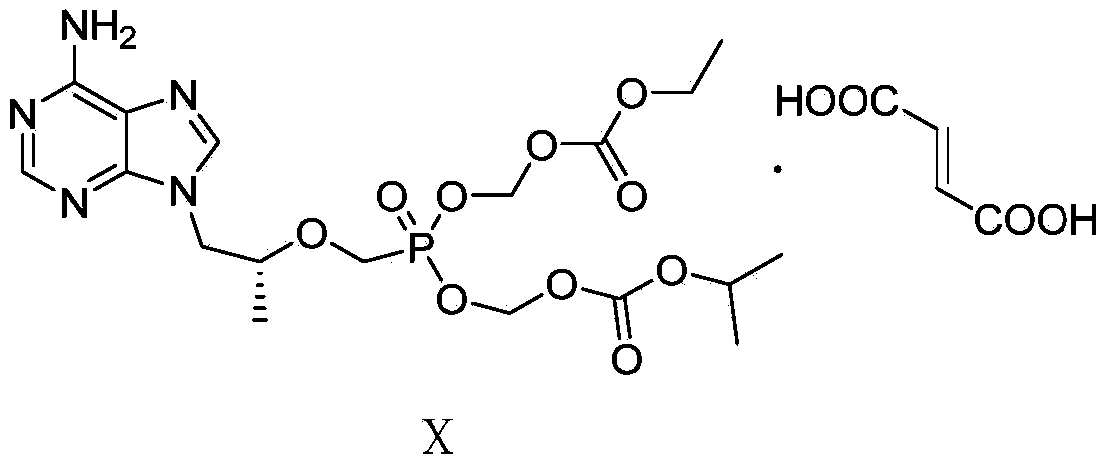

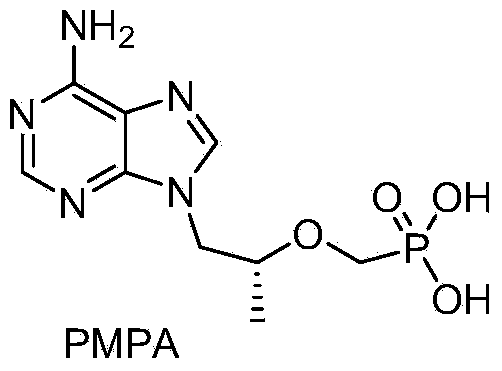

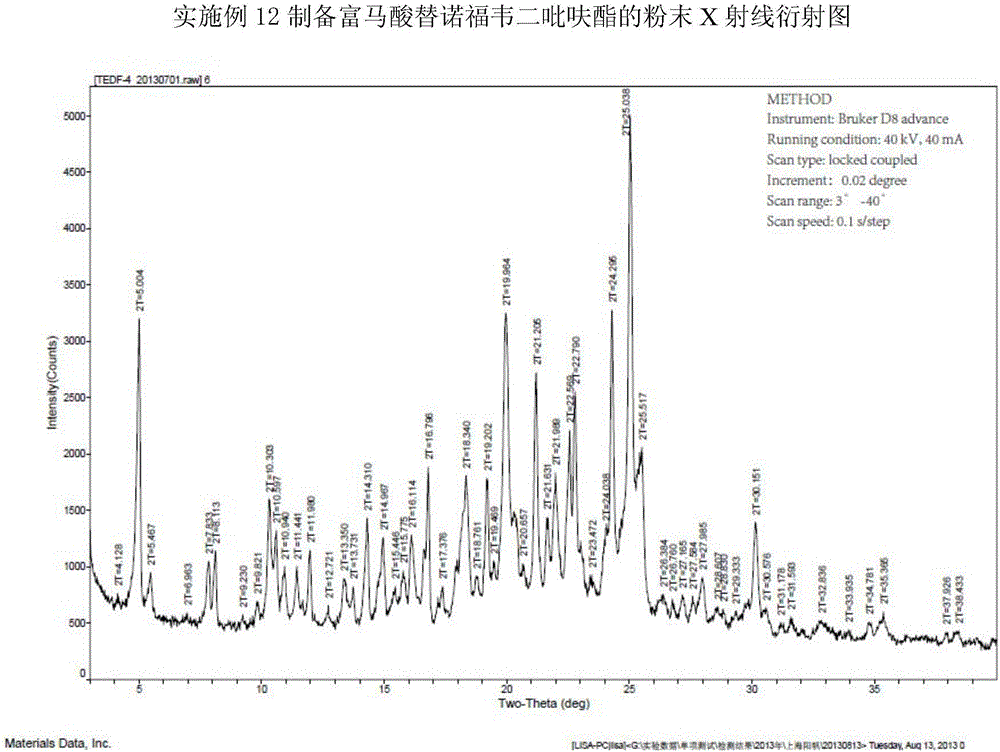

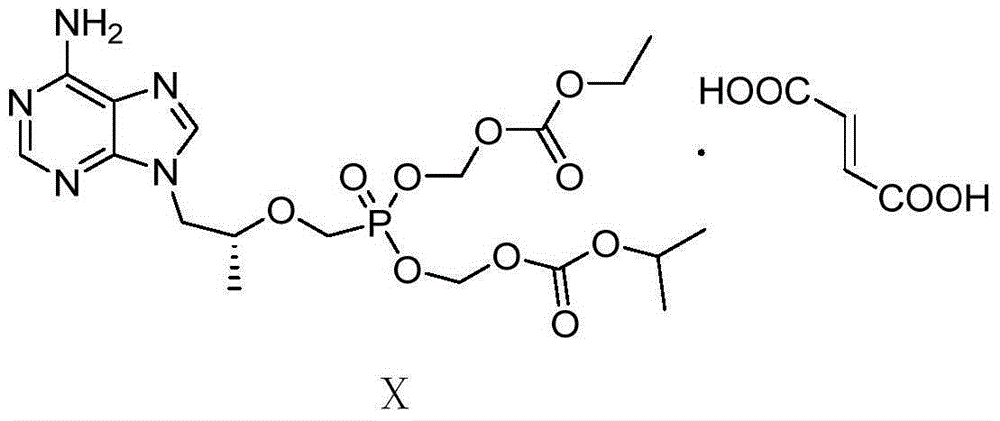

Tenofovir disoproxil fumarate and preparation method thereof

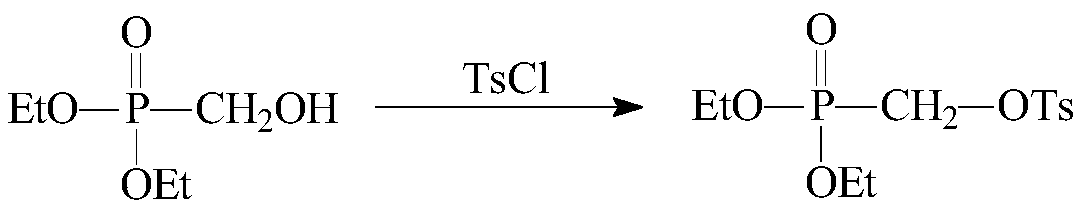

ActiveCN103641858AAdvantages and Notable ImprovementsSignificant progressGroup 5/15 element organic compoundsAntiviral drugDimethyl methylphosphonate

The invention relates to an antiviral drug tenofovir disoproxil fumarate and a novel preparation method thereof, belonging to the field of medicines. Content of related substances in the tenofovir disoproxil fumarate, especially content of impurity K is effectively lowered by taking toluenesulfonyloxy diethyl methylphosphonate as a starting material through hydrolysis, condensation and salifying. Moreover, the preparation method is gentle in reaction condition, low in production cost, simple and convenient to operate, and suitable for large-scale industrial production.

Owner:湖南千金湘江药业股份有限公司

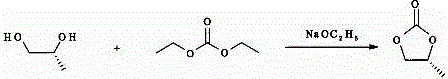

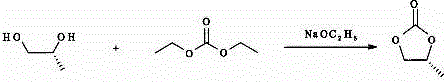

Industrialization production technology for tenofovir disoproxil fumarate

InactiveCN105859781AHigh yieldHigh purityGroup 5/15 element organic compoundsDiethyl phosphateDiethyl methylphosphonate

An industrial production process of tenofovir, the production process steps are as follows: add R-1,2-propylene glycol, diethyl carbonate and sodium ethylate into the reaction kettle; add absolute ethanol and diphosphite Ethyl ester, stirring, after the stirring is completed, put in paraformaldehyde and triethylamine, after the reaction is complete, add anhydrous sodium sulfate, dry, filter, and distill out, the distilled product is diethyl p-toluenesulfonyloxymethylphosphonate Fine product; add adenine, R-propylene carbonate, DMF and NaOH in the reaction kettle, after the reaction is complete, add magnesium tert-butoxide, drop diethyl p-toluenesulfonyl phosphate, after the reaction is complete, add acetic acid, Concentrate under reduced pressure, add hydrochloric acid, filter, filter out the solid and dry under normal pressure to obtain PMPA fine product. The method has the advantages of high yield, high product purity and low impurity content, and can be fully industrialized.

Owner:JINGMEN SHUAIBANG CHEM SCI & TECHCO

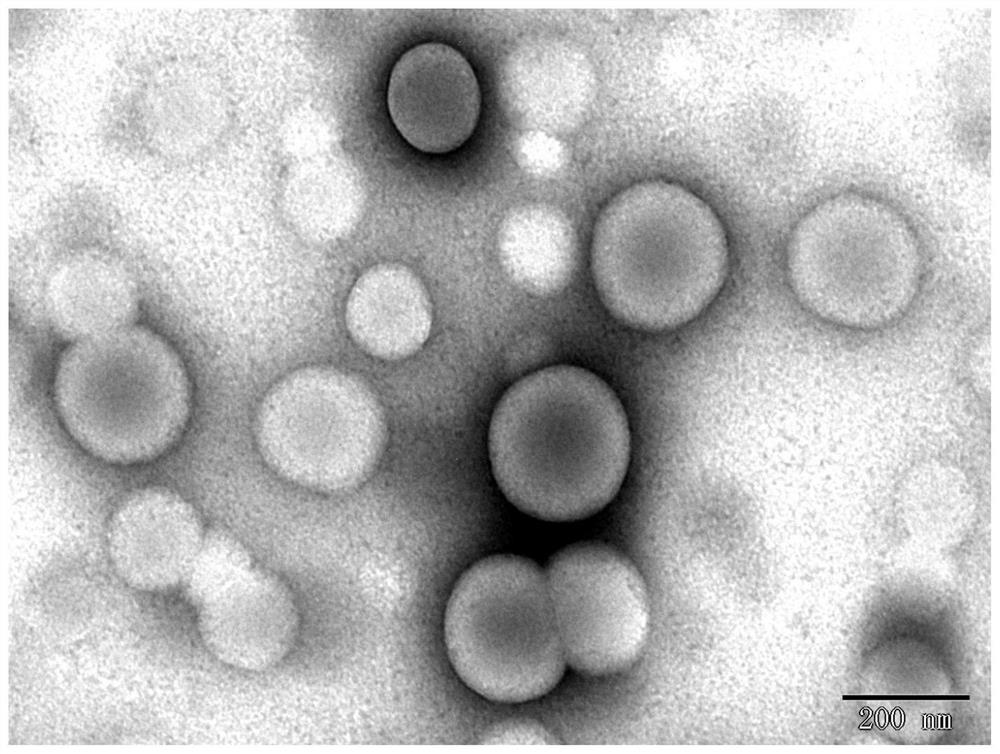

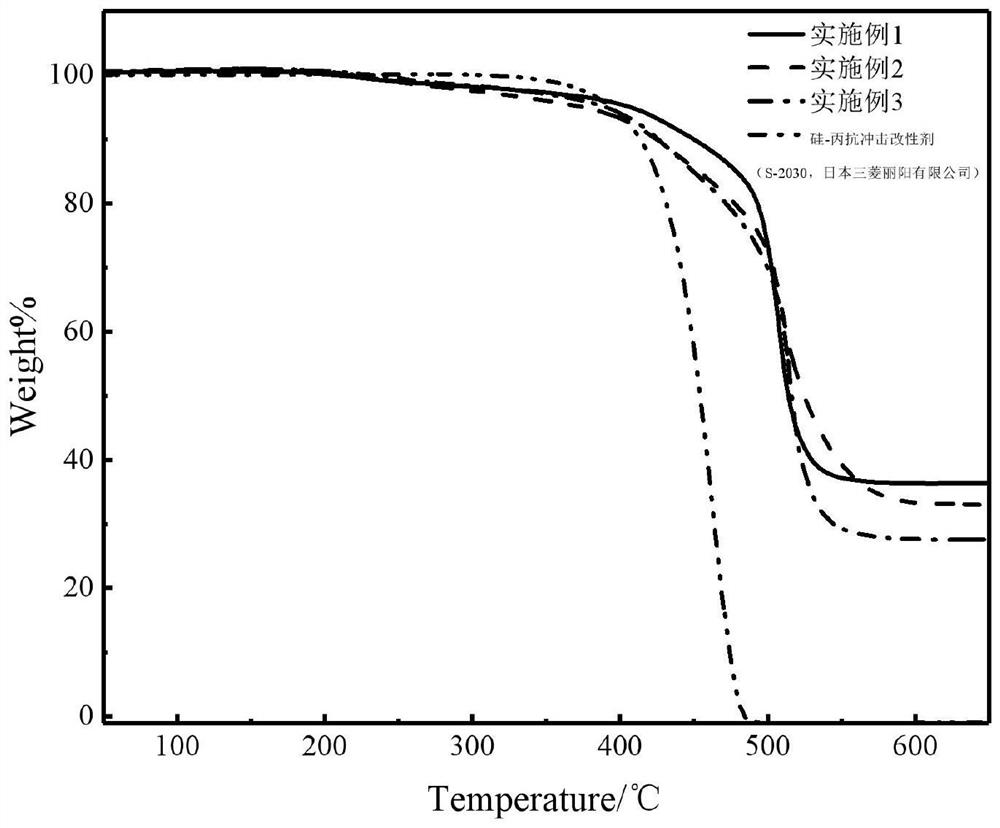

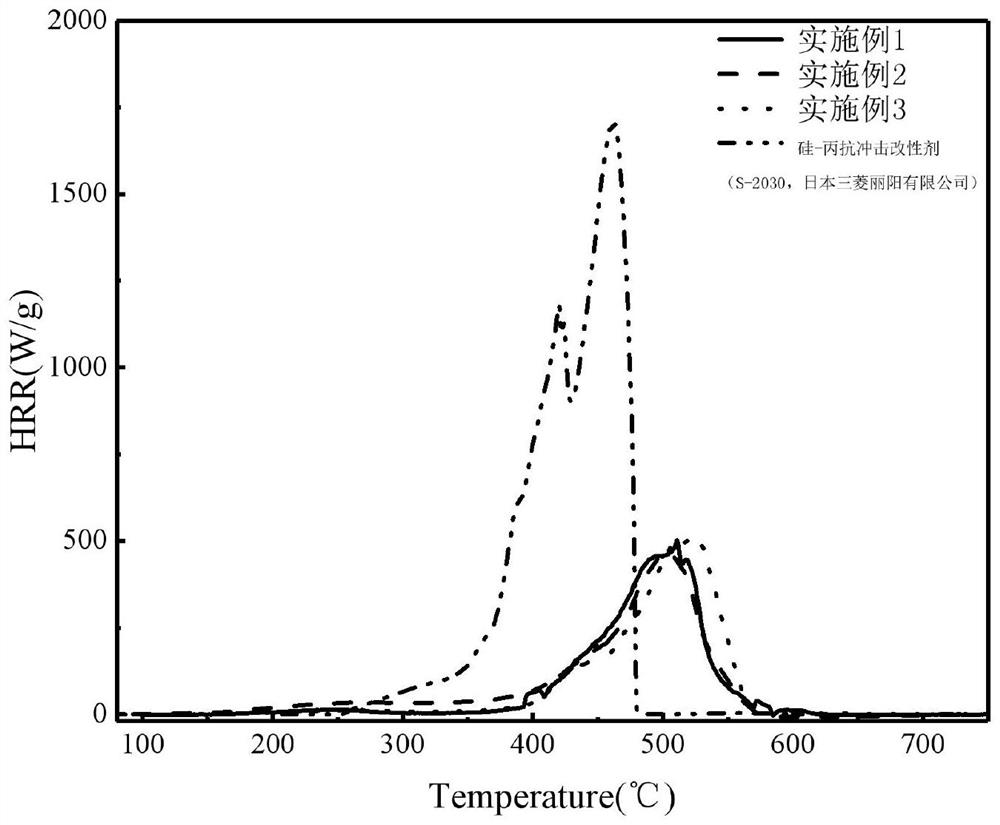

Organosilicon-phosphorus-containing acrylate core-shell toughening flame retardant and preparation method thereof

ActiveCN114292368ASolve the problem of mechanical properties, especially the decline of impact toughnessHigh residual qualityElastomerPolymer science

The invention provides an organic silicon-phosphorus-containing acrylate core-shell toughening flame retardant and a preparation method thereof, and belongs to the technical field of design and synthesis of flame retardants. The organic silicon-phosphorus-containing acrylate core-shell toughening flame retardant provided by the invention is prepared by taking octamethylcyclotetrasiloxane as a core layer (D4), KH570 as a cross-linking agent and diethyl methylphosphonate acrylate (DEAMP) and DOPO acrylate as a shell layer through an emulsion polymerization method. The toughening flame retardant prepared by the invention has dual functions of a core-shell elastomer and a macromolecular flame retardant, and the glass-transition temperature of a rubber phase is far lower than room temperature; the phosphorus content is high, and the P-Si synergistic flame-retardant effect is achieved; the initial thermal decomposition temperature is higher than 360 DEG C, and the residual mass after decomposition is higher than 30%.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

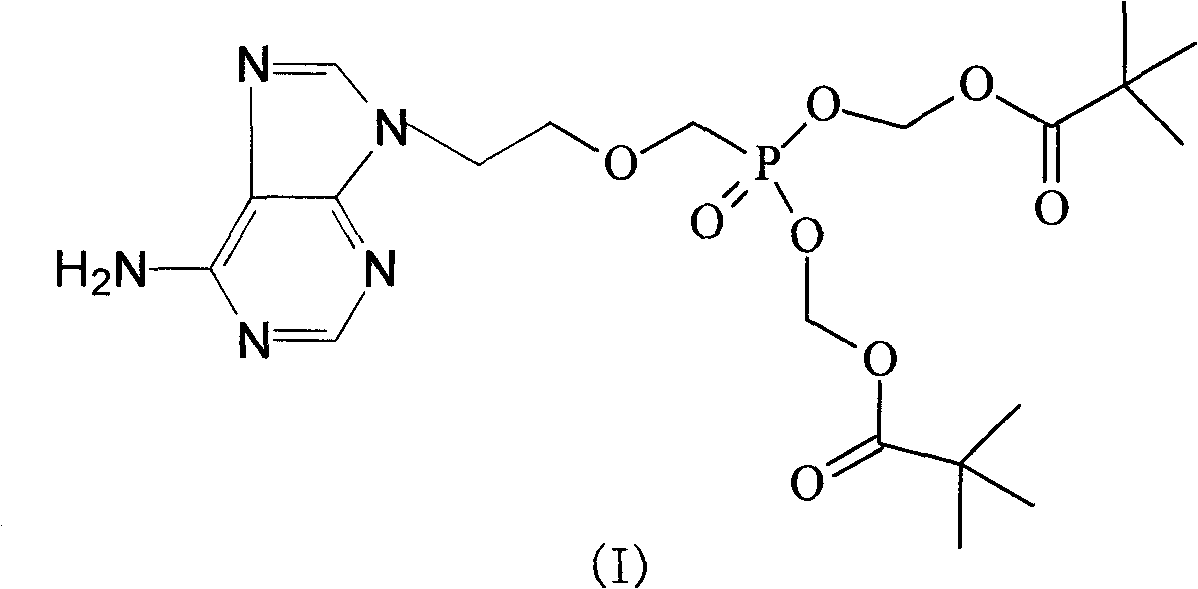

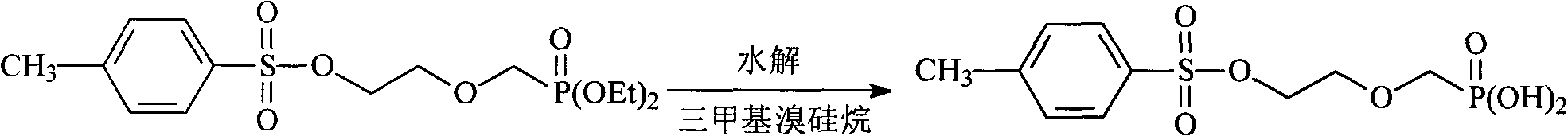

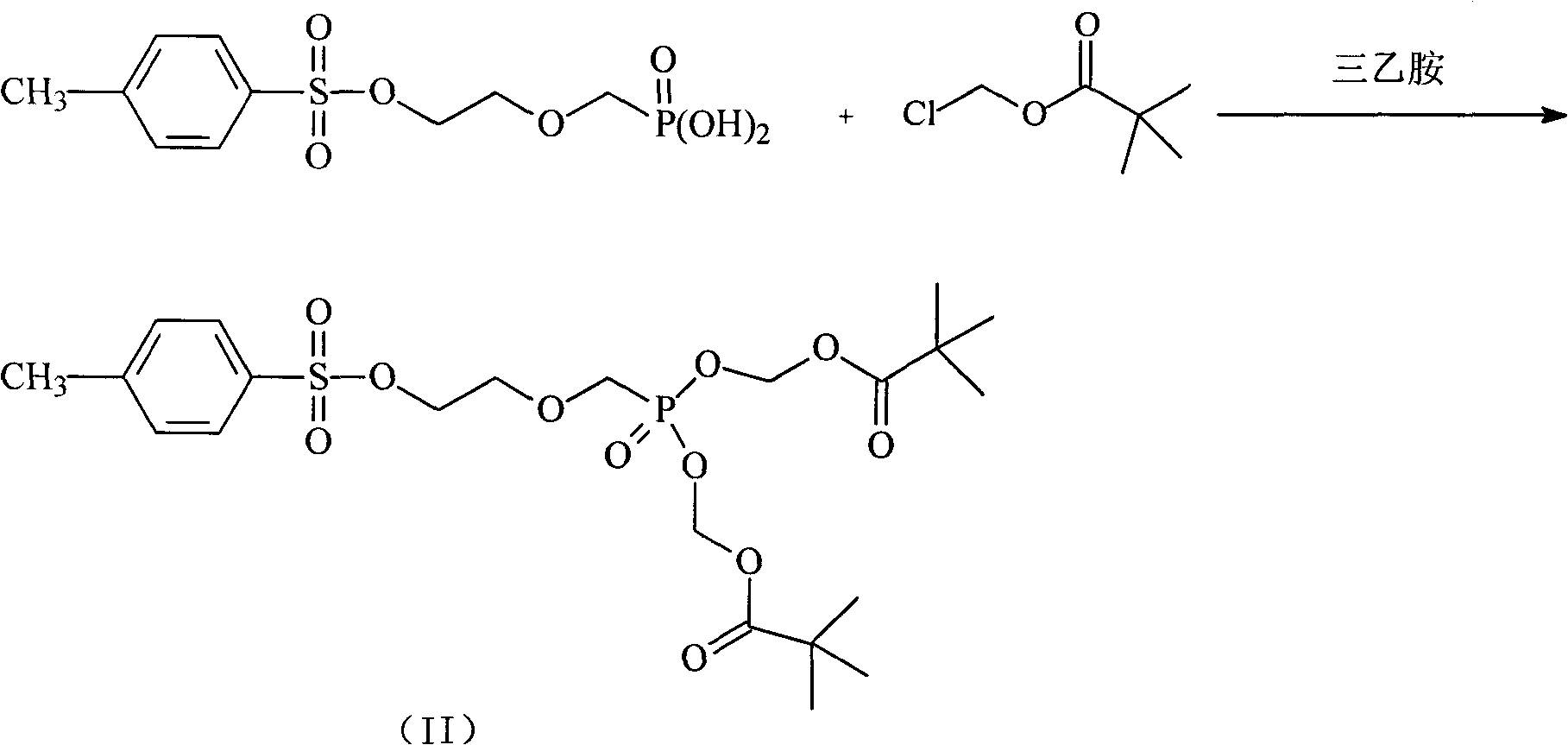

Adefovir dipivoxil compound and novel preparation method thereof

InactiveCN101812089AReduce the introductionHigh purityGroup 5/15 element organic compoundsDiethyl methylphosphonateMethylphosphinic acid

The invention aims to provide an adefovir dipivoxil compound and a novel preparation method thereof; the method specifically comprises the following steps that: (2-p-toluenesulfonyloxy ethoxy) diethyl methylphosphonate is hydrolyzed at low temperature, to prepare (2-p-toluenesulfonyloxy ethoxy) methyl phosphonic acid; chloro methyl pivalate is added in to react and prepare an intermediate body (II) under the action of triethylamine; and adenine and the intermediate body (II) react to prepare adefovir dipivoxil under the catalysis of anhydrous potassium carbonate. The invention reduces the introduction of impurities, improves the purity, and lays foundation for industrial production.

Owner:HAINAN YONGTIAN PHARMA INST

Preparation method of high-purity tenofovir

The invention provides a preparation method of high-purity tenofovir. The method at least comprises the following steps: (1) preparing R-propylene carbonate; (2) purifying a catalyst; (3) carrying outcondensation reaction on adenine with R-propylene carbonate; (4) carrying out etherification reaction on 9-(2-hydroxypropyl) adenine with diethyl p-toluenesulfonyloxymethylphosphonate; (5) carrying out hydrolysis reaction on tenofovir diester; and (6) refining crude tenofovir.

Owner:科兴生物制药股份有限公司

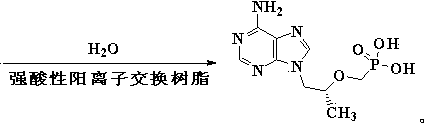

Tenofovir synthesizing method

ActiveCN109053804ANot corrosiveHigh catalytic activityGroup 5/15 element organic compoundsChemical recyclingDiethyl methylphosphonateDistillation

The invention discloses a tenofovir synthesizing method. According to the method, diethyl p-toluenesulfonyloxymethylphosphonate (TSDEP), (R)-9-(2-hydroxyl propyl)adenine (HPA) and a solid base catalyst like KOH / Al2O3, strong acid cation exchange resin and the like are utilized as raw materials; a product is prepared by aftertreatment operation of condensing, hydrolysis two-step reaction, filtration, reduced pressure distillation, cooling and the like. The method disclosed by the invention has the characteristics of sufficient raw material sources, low cost, high synthesizing technology safety,high product yield, small three-waste pollution and higher industrial value; furthermore, the solid alkali catalyst and the strong acid cation exchange resin are easy to recycle and suitable for setuse after regeneration.

Owner:LEPING SAFELY PHARMA

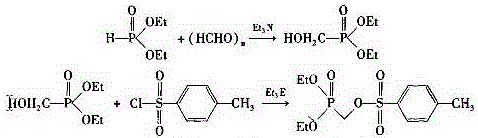

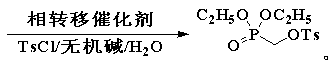

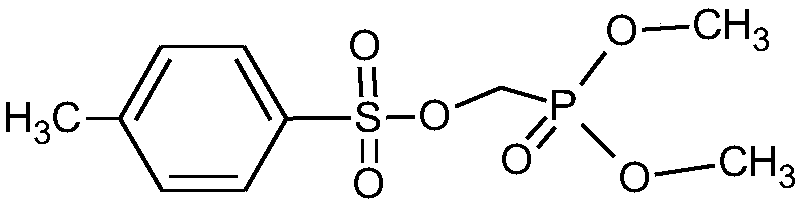

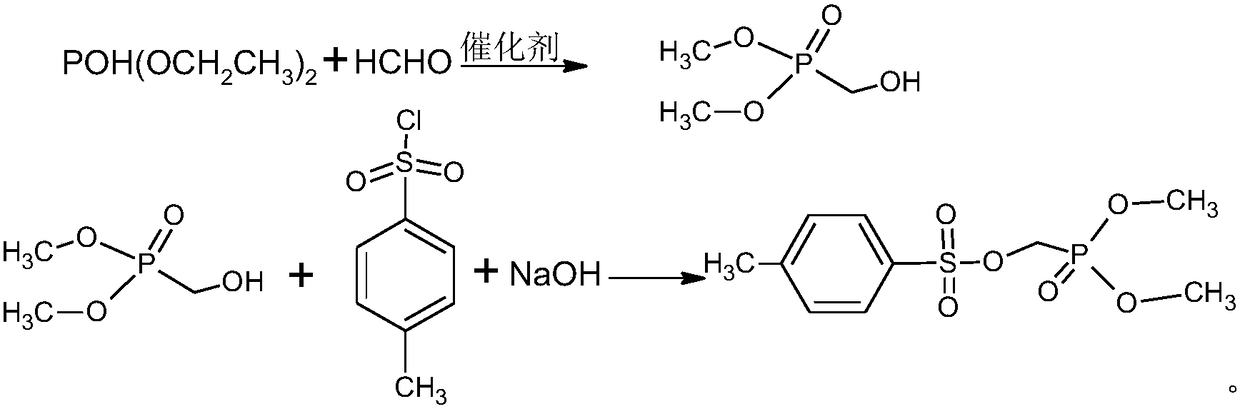

Diethyl p-toluenesulfonyloxy methylphosphonate synthesis method

InactiveCN105541910AShort reaction timeReduce energy consumptionGroup 5/15 element organic compoundsDiethyl methylphosphonateDistillation

The invention relates to the technical field of medicine, and specifically relates to a synthesis method of diethyl p-toluenesulfonyloxy methylphosphonate. The method comprises the following steps: (1) diethyl hydroxymethylphosphonate is synthesized, wherein diethyl phosphite, a solvent, a catalyst and paraformaldehyde are sequentially added into a reactor; heating is carried out and a reaction is allowed; filtering is carried out after the reaction; the solvent is removed through distillation, and the remaining substance is diethyl hydroxymethylphosphonate; and (2) diethyl p-toluenesulfonyloxy methylphosphonate is synthesized, wherein diethyl hydroxymethylphosphonate prepared in the step (1) is cooled; dichloromethane and p-toluenesulfonyl chloride are added; an acid binding agent is dropped in, and stirring is continuous for 1.5-2.5h after dropping; heating is carried out and a reaction is allowed; after the reaction, extraction, water washing and distillation are carried out, and the remaining substance is a crude product; and purification is carried out, such that a diethyl p-toluenesulfonyloxy methylphosphonate product is obtained. The method provided by the invention has the advantages of low energy consumption, simple product post treatment, high yield and high product purity. The yield can be higher than 80%. The purity can be higher than 99%.

Owner:SHANDONG JINCHENG PHARMA & CHEM

Synthetic method for adefovir dipivoxil

InactiveCN103804415AMild reaction conditionsEasy to operateGroup 5/15 element organic compoundsPhosphorous acidDiethyl methylphosphonate

The invention relates to an improved synthetic method for adefovir dipivoxil. The synthetic method for adefovir dipivoxil provided by the invention has the advantages of mild reaction conditions, convenient operation and high yield. The synthetic method comprises the following steps: step 1, synthesis of diethyl phosphite; step 2, synthesis of diethyl p-toluenesulfonyloxymethylphosphonate; step 3, synthesis of 9-(2-hydroxyethyl)adenine; step 4, synthesis of 9-[2-(diethylphosphonomethoxy)ethyl]adenine; step 5, synthesis of adefovir; and step 6, synthesis of adefovir dipivoxil.

Owner:姜丹宁

Low-viscosity flame-retardant polyurethane metal paint

InactiveCN105385327AEvenly dispersedEvenly distributedFireproof paintsAnti-corrosive paintsSodium BentoniteDiethyl methylphosphonate

The invention discloses a low-viscosity flame-retardant polyurethane metal paint. The paint comprises the following raw materials in parts by weight: 80 to 85 parts of modified polyurethane, 6 to 9 parts of aqueous organic silicone resin, 12 to 15 parts of aqueous aldehyde-ketone resin, 22 to 25 parts of talcum powder, 3 to 6 parts of bentonite, 5 to 8 parts of kaolin, 8 to 12 parts of calcium carbonate, 10 to 14 parts of nano magnesium hydroxide, 3 to 4 parts of antiseptic, 2 to 3 parts of antifoaming agent, 2.5 to 4 parts of flatting agent, and 5 to 6 parts of pigment; wherein the modified polyurethane is prepared from the following components: polyhexanedioic acid-1,4-butanediol ester diol, polytetrahydrofuran, N,N-bis(2-hydroxyethyl)amino methylene diethyl phosphonate, modified polymerized 1,6-hexamethylene diisocyanate, 1,6-hexanediol, 1,4-butanediol-sodium sulfonate, epoxy resin, cobalt octoate, N-methyl diethanolamine, and diethanolamine, and modified polymerized 1,6-hexamethylene diisocyanate is prepared by the following steps: polymerizing 1,6-hexamethylene diisocyanate and then grafting hydroxyl siloxane to the polymerized 1,6-hexamethylene diisocyanate.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

Water-resistant flame-retardant polyurethane metal paint

InactiveCN105385326AImprove lipophilicityImprove crosslink strengthFireproof paintsPolyurea/polyurethane coatingsDiethyl methylphosphonateMelamine formaldehyde resin

The invention discloses a water-resistant flame-retardant polyurethane metal paint. The paint comprises the following raw materials: flame-retardant polyurethane, aqueous melamine-formaldehyde resin, aqueous acrylic resin, sodium carboxymethyl cellulose, bentonite, diatomite, nano titanium dioxide, micro-encapsulation red phosphorus, antiseptic, antifoaming agent, flatting agent, and pigment. The preparation method of flame-retardant polyurethane comprises the following steps: mixing tung oil polyol and N,N-bis(2-hydroethyl)amino methylene diethyl phosphite, heating the mixture, maintaining the temperature, carrying out vacuum dehydration to obtain a first material; mixing m-phenylene dimethylene isocyanate and the first material, heating, maintaining the temperature, cooling, adding trimethyl pentanediol, dihydroxymethyl butyric acid, glucose, and acetone, then adding dibutyl tin dilaurate, heating, maintaining the temperature, cooling, dropwise adding a mixed solution containing bis(2-hydroxypropyl)aniline and N-butyl diethanolamine, heating, maintaining the temperature, carrying out neutralization, adding water to carry out emulsification and dispersion, and finally performing vacuum distillation to obtain the flame-retardant polyurethane. The provided paint has excellent flame-retardant and water-resistant properties.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

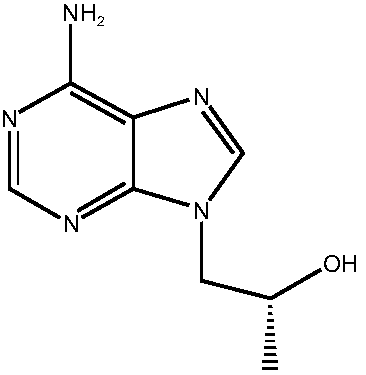

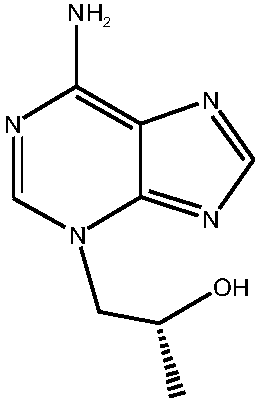

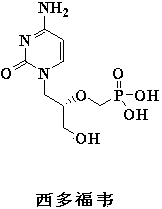

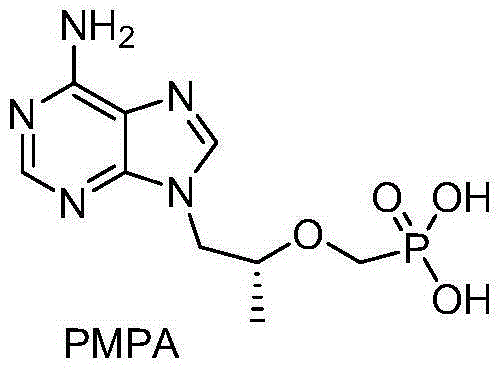

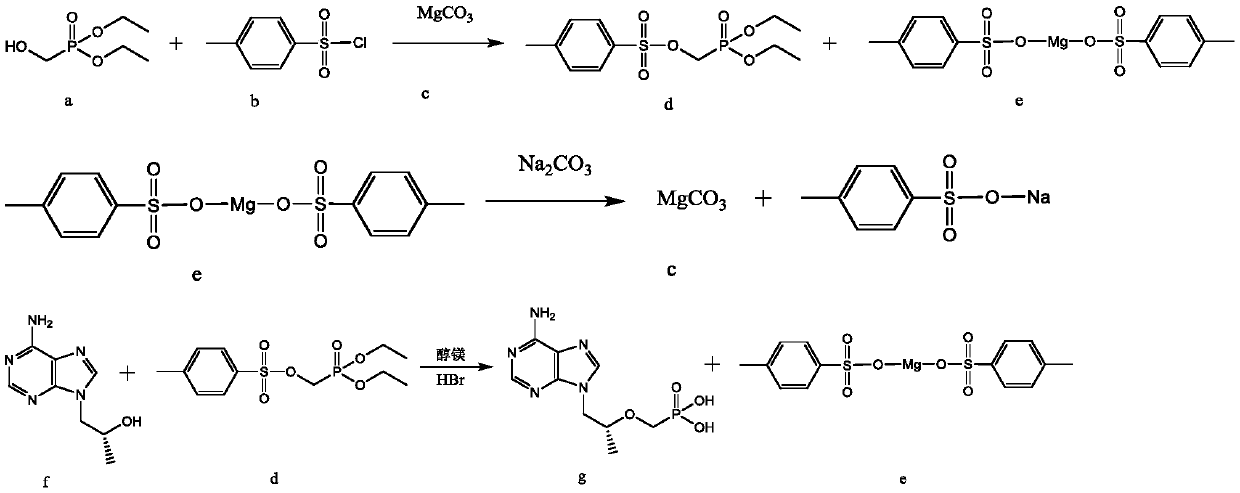

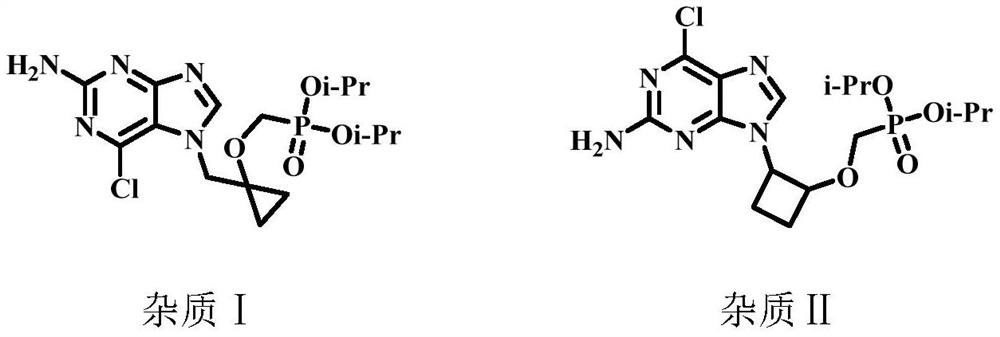

Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine

InactiveCN105254670ALow costReduce pollutionGroup 5/15 element organic compoundsAfter treatmentDiethyl methylphosphonate

The invention relates to a preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine. The preparation method comprises the steps of taking (R)-9-(2-hydroxypropyl) adenine as an initial compound and dissolving the (R)-9-(2-hydroxypropyl) adenine into DMF (dimethyl formamide), using lithium amide to participate in a reaction, slowly dropwise adding diethyl p-toluenesulfonyloxymethyl phosphonate, then, performing a heating reaction, and after treatment, using hydrobromic acid to remove ethyl, so as to obtain the (R)-9-[2-(Phosphonomethoxy) propyl] adenine. The initial material used by the preparation method is easy to obtain, safe and stable, the synthetic method is simple to operate, the product yield is high, the purity is high, the pollution to environment is relatively small, and a simple and feasible method is provided for the mass production of the compound, namely the (R)-9-[2-(Phosphonomethoxy) propyl] adenine.

Owner:天津药物研究院药业有限责任公司

Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate

ActiveUS7687631B2Improve production yieldMaterial safetyAntipyreticGroup 5/15 element organic compoundsArylLeaving group

Owner:XSPIRE PHARMA LLC

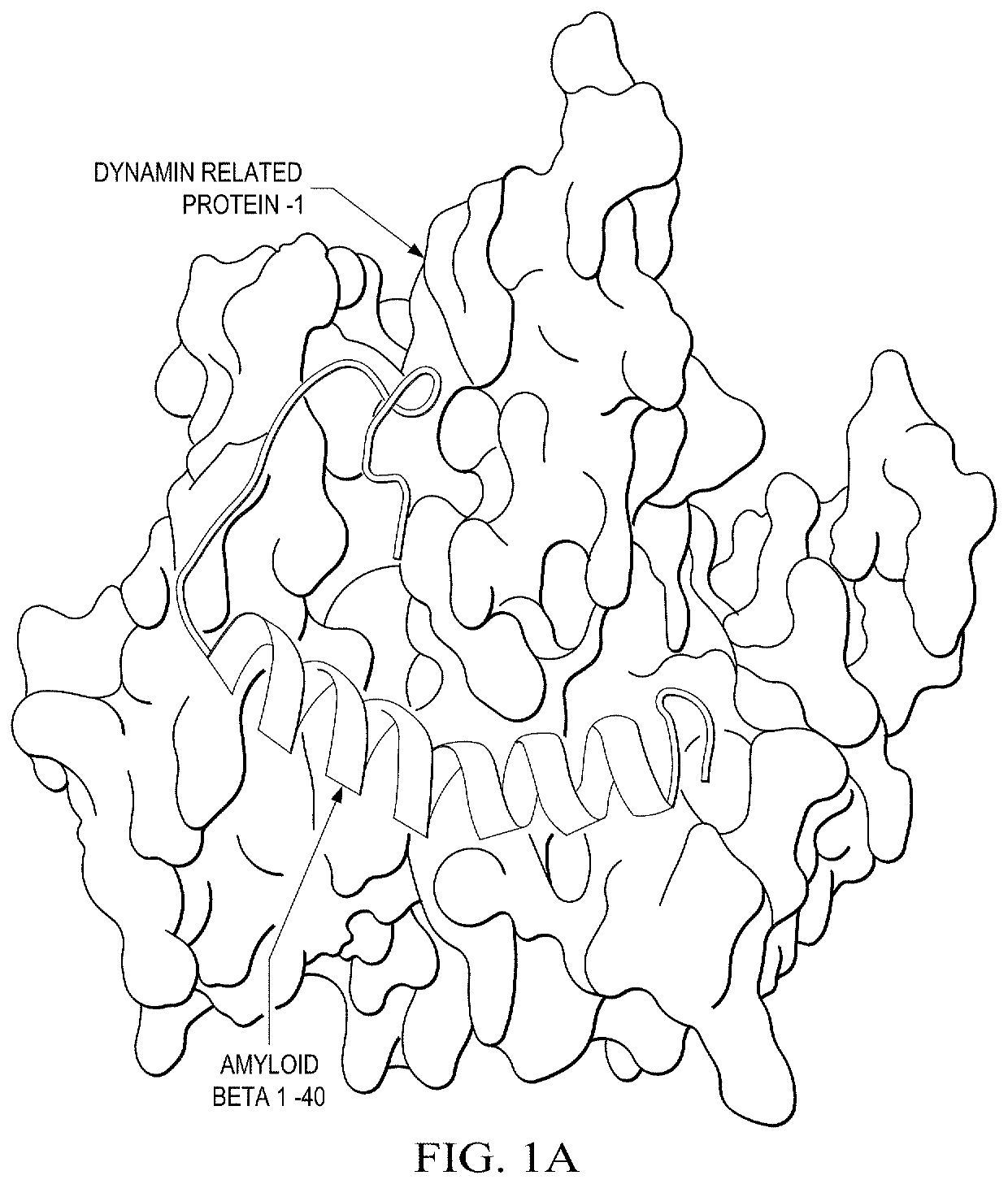

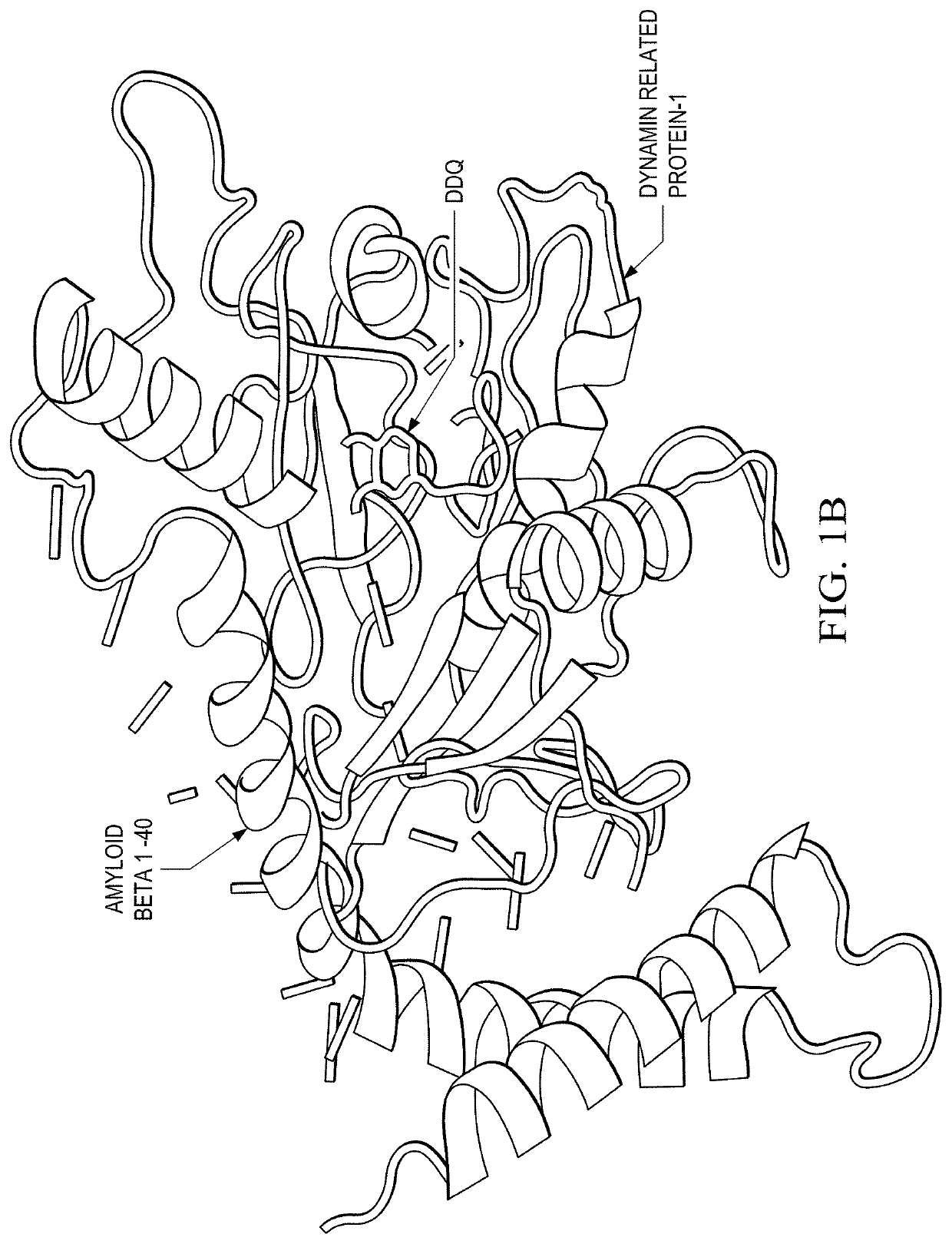

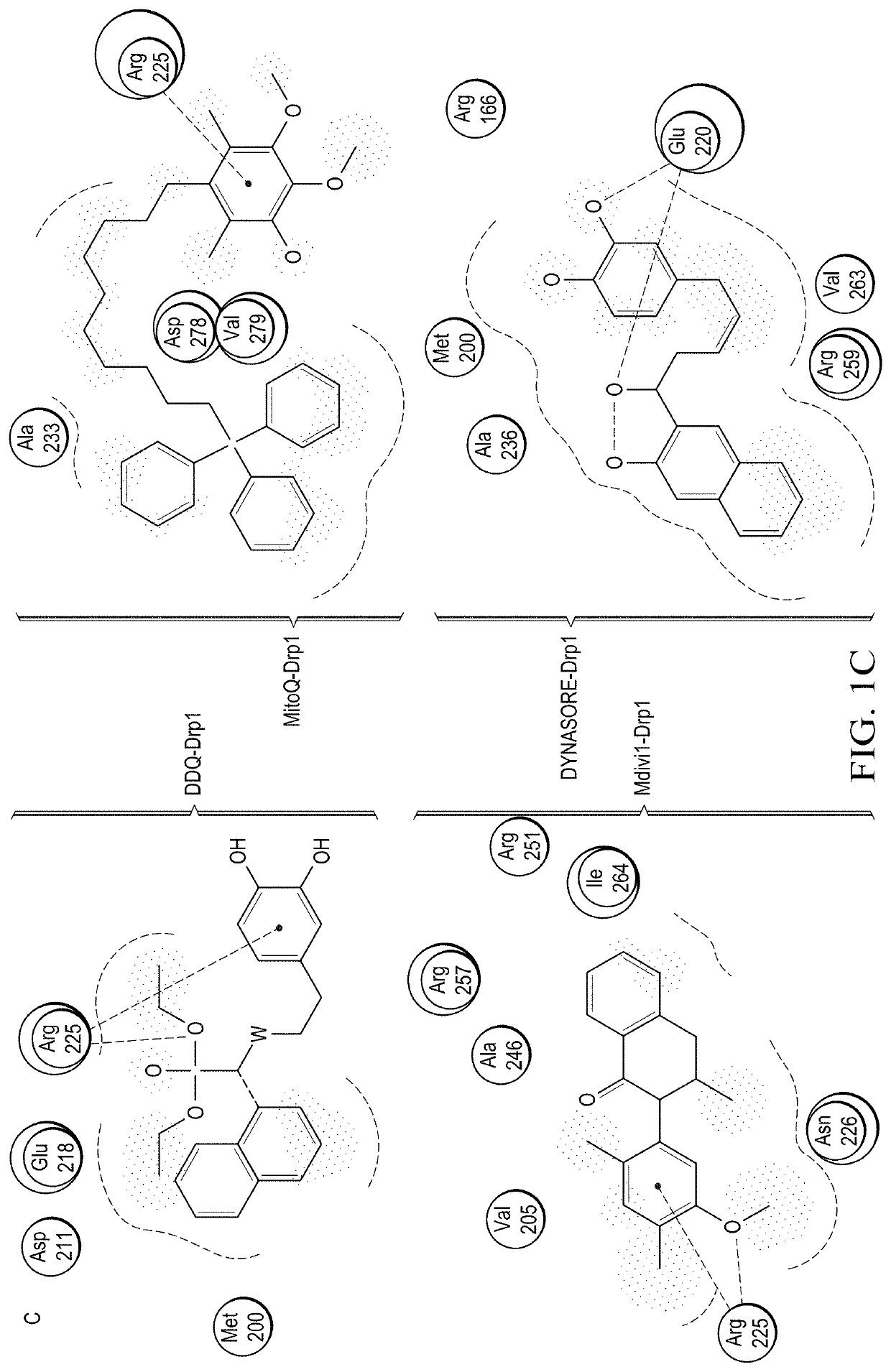

Drug Targets of Delayed Aging and Human Brain Diseases

ActiveUS20190374558A1Reduce/prevent interactionHigh binding affinityNervous disorderPhosphorous compound active ingredientsDiethyl methylphosphonateCarboxylic acid

The present invention includes a molecule, a method of identifying said molecule, and a method of using said molecule to inhibit the interaction of Aβ and Drp1 proteins. The molecules including diethyl (3,4-dihydroxyphenethylamine)(quino-lin-4-yl)methylphosphonate (DDQ); [10-(4,5-dimethoxy2-methyl-3,6-dioxo-1,4-cyclohexadien-1-yl)decyl]triphenylphosphonium methanesulfonate (MitoQ); 3-Hydroxynaphthalene-2-carboxylic acid (3,4-dihydroxy-benzylidene)-hydrazide (Dynasore); and / or 3-(2,4Dichloro-5-methoxyphenyl)-2,3-dihydro-2-thioxo-4(1H)-quinazolinone / 3-(2,4-Dichloro-5-methoxyphenyl)-2-sulfanyl-4(3H)-quinazolinone (Mdivi-1).

Owner:TEXAS TECH UNIV SYST

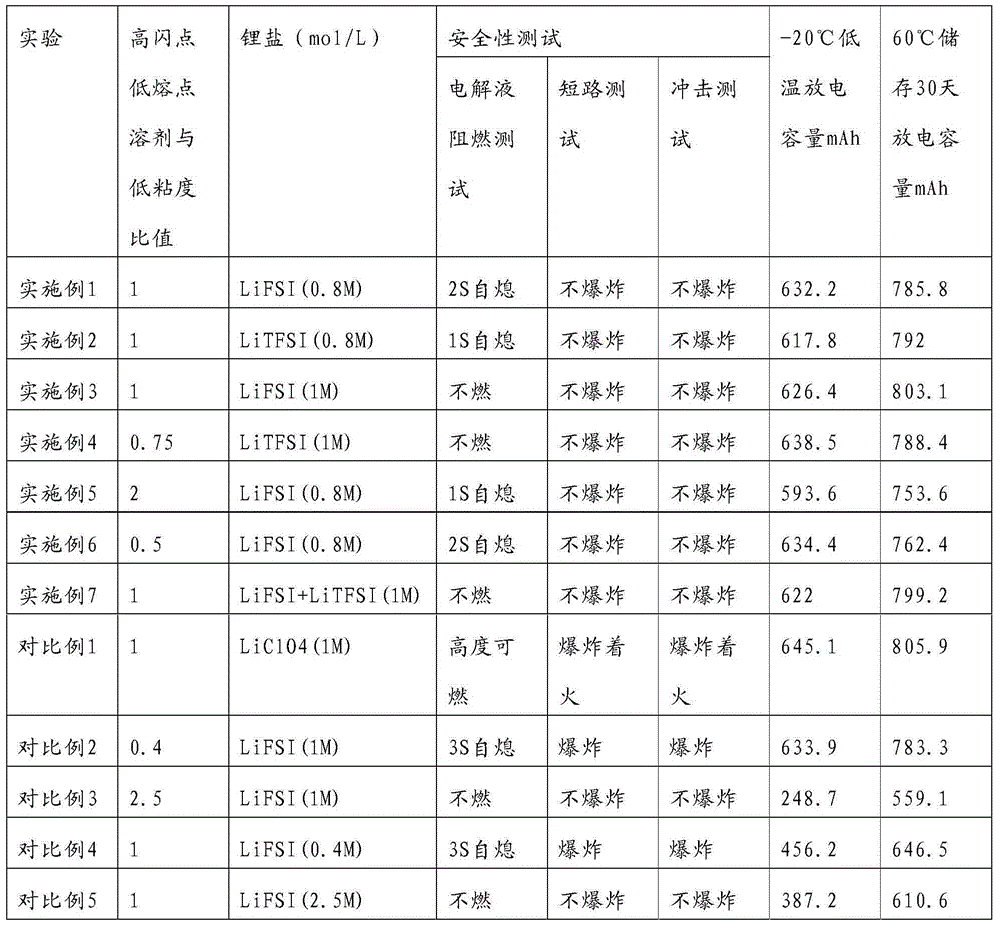

Non-aqueous electrolyte of primary lithium battery and primary lithium battery

ActiveCN105098247AGuaranteed low temperature discharge performanceAvoid high temperature inflationSecondary cellsElectrolytesHigh temperature storageDimethyl methylphosphonate

The invention relates to non-aqueous electrolyte of a primary lithium battery. The non-aqueous electrolyte comprises a lithium salt, a high-flash-point and low-melting-point solvent and a low-viscosity solvent, wherein the high-flash-point and low-melting-point solvent comprises at least one of propylene carbonate, dimethyl methylphosphonate, diethyl methylphosphonite, diethyl ethanephosphonate, dimethyl ethylphosphonate and gamma-butyrolactone; the flash point of the high-flash-point and low-melting-point solvent is greater than 60 DEG C; the melting point is less than 40 DEG C; the low-viscosity solvent comprises at least one of glycol dimethyl ether, diethylene glycol dimethyl ether, ethylene glycol methyl ether, 1,3-dioxolame, tetrahydrofuran, methyl acetate, ethyl acetate, propyl acetate, methyl propionate, ethyl propionate and propyl propionate; and the viscosity of the low-viscosity solvent is less than 1mPa.s. The invention further relates to the primary lithium battery. The non-aqueous electrolyte of the primary lithium battery provided by the invention has the advantages of high safety performance, good high-temperature storage performance and low-temperature discharge performance.

Owner:SHENZHEN CAPCHEM TECH

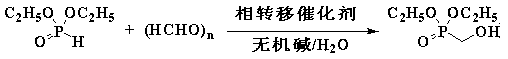

Synthesis method of diethyl (tosyloxy)methylphosphonate

ActiveCN109053799AEmission reductionImprove securityGroup 5/15 element organic compoundsDiethyl methylphosphonateSynthesis methods

The invention discloses a synthesis method of diethyl (tosyloxy)methylphosphonate. The method takes diethyl phosphite, paraformaldehyde, paratoluensulfonyl chloride, inorganic base and the like as rawmaterials, and the product is obtained by carrying out carrying out aftertreatment operations such as aqueous phase condensation, an esterification two-step reaction and layering. The method has thecharacteristics of being enough in raw materials source, low in price, high in safety of synthetic process, high in product yield, less in pollution caused by three wastes, environmentally-friendly, and the like, thus having a higher industrial value.

Owner:LEPING SAFELY PHARMA

A kind of tenofovir disoproxil fumarate and preparation method thereof

ActiveCN103641858BAvoid it happening againSolve the problem of exceeding the limit of genotoxic impuritiesGroup 5/15 element organic compoundsAntiviral drugFumarate Esters

The invention relates to an antiviral drug tenofovir disoproxil fumarate and a novel preparation method thereof, belonging to the field of medicines. Content of related substances in the tenofovir disoproxil fumarate, especially content of impurity K is effectively lowered by taking toluenesulfonyloxy diethyl methylphosphonate as a starting material through hydrolysis, condensation and salifying. Moreover, the preparation method is gentle in reaction condition, low in production cost, simple and convenient to operate, and suitable for large-scale industrial production.

Owner:湖南千金湘江药业股份有限公司

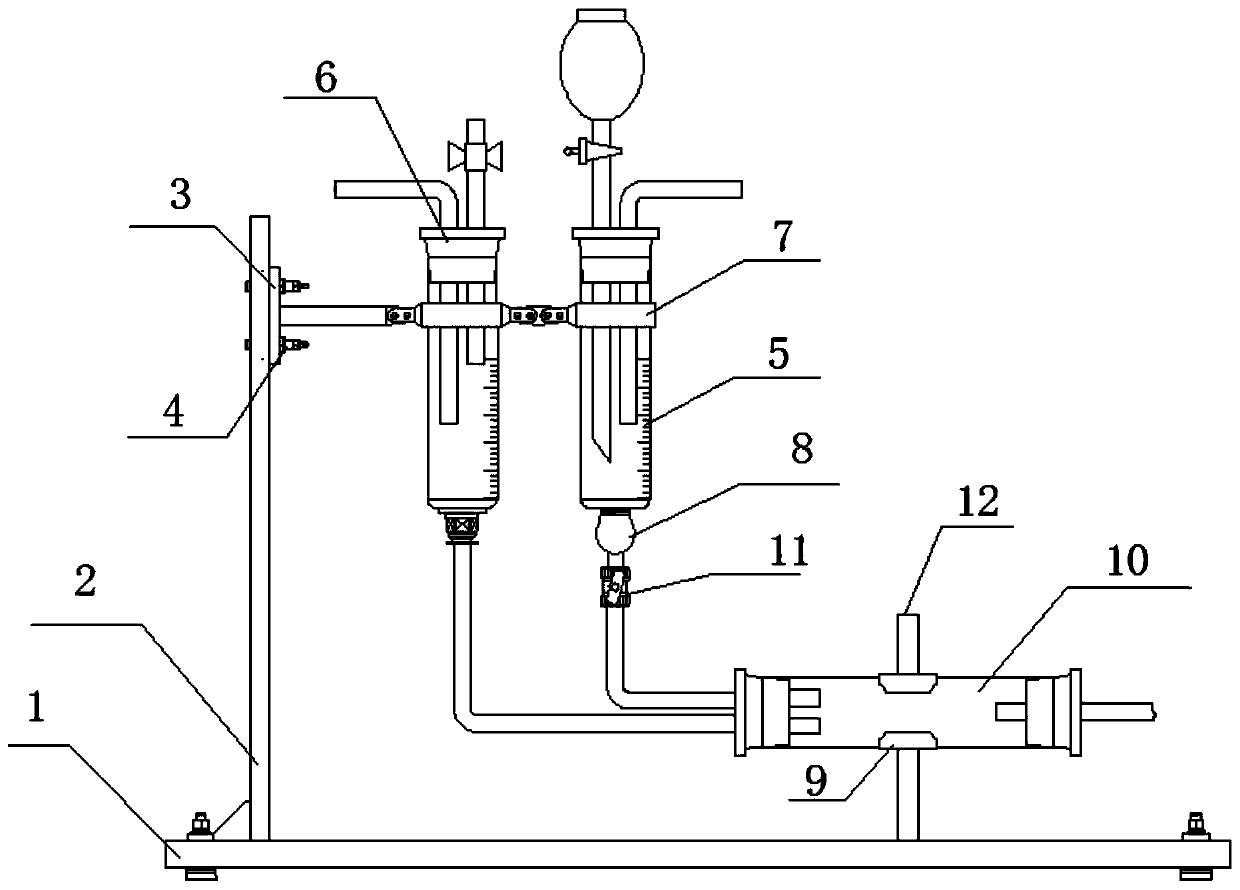

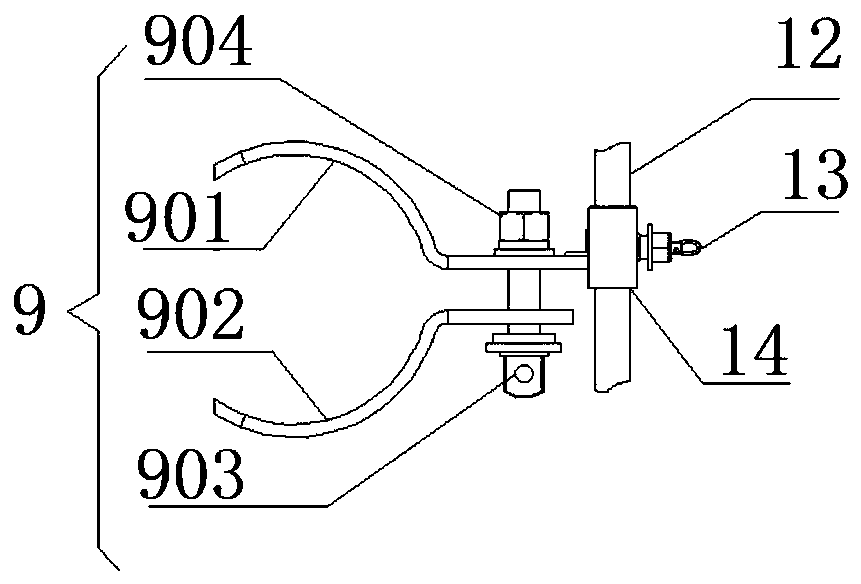

Method for recycling byproduct p-toluene magnesium sulfonate to synthesize tenofovir

InactiveCN110183491AAchieve recyclingThe reaction process is simpleGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsDiethyl phosphateDiethyl methylphosphonate

The invention relates to the technical field of medicine chemicals and in particular discloses a method for recycling a byproduct p-toluene magnesium sulfonate to synthesize tenofovir. According to the method, hydroxymethylphosphonic acid diethyl ester and paratoluensulfonyl chloride are adopted as raw materials, magnesium carbonate is adopted as an acid-binding agent, p-toluenesulfonyl oxymethyldiethyl phosphate is synthesized, tenofovir is synthesized from the p-toluenesulfonyl oxymethyl diethyl phosphate and R-9-(2-hydroxypropyl), and meanwhile, a byproduct p-toluene magnesium sulfonate isgenerated; and magnesium carbonate and sodium p-toluenesulfonate are generated through a reaction of the p-toluene magnesium sulfonate and sodium carbonate. According to the method, the byproduct p-toluene magnesium sulfonate is mainly recycled, process treatment difficulties are reduced, byproducts p-toluene magnesium sulfonate and magnesium chloride which are obtained after treatment are high in purity, export sales can be achieved, the magnesium carbonate can be applied to synthesis of the p-toluenesulfonyl oxymethyl diethyl phosphate, and the production cost can be reduced.

Owner:黄石福尔泰医药科技有限公司

Method for synthesizing diethyl (tosyloxy)methylphosphonate

InactiveCN109021011AHigh purityHigh molar yieldGroup 5/15 element organic compoundsDiethyl methylphosphonateSolvent

The invention discloses a method for synthesizing diethyl (tosyloxy)methylphosphonate. The method comprises the following steps: mixing a 37% aqueous formaldehyde solution with a catalyst, dropwise adding diethyl phosphite, carrying out a heat insulation reaction for 2 h after the dropwise addition is completed in order to obtain a reaction solution, adding a solvent and p-toluenesulfonyl chlorideto the reaction solution, dropwise adding an acid binding agent at a low temperature, carrying out heat insulation for about 2 h after the dropwise addition is completed, performing extraction, washing the obtained reaction product with water, and distilling the washed reaction product to obtain a remaining material that is highly-pure for synthesizing diethyl (tosyloxy)methylphosphonate. The method overcomes the disadvantages of low purity, low yield, complicated process, troublesome post-treatment, large environmental protection pressure and unsuitability for industrialization in the priorart.

Owner:山东沾化永浩医药科技有限公司

High-curing-speed low-viscosity polyurethane metal paint

InactiveCN105419614ALow viscositySmall elongation at breakFireproof paintsAnti-corrosive paintsWater basedDiethyl methylphosphonate

The invention discloses a high-curing-speed low-viscosity polyurethane metal paint. The high-curing-speed low-viscosity polyurethane metal paint comprises the following raw materials in parts by weight: 75-85 parts of tripolymer modified polyurethane, 20-25 parts of water-based acrylic resin, 5-10 parts of water-based phenolic resin, 3-6 parts of fumed silica, 12-15 parts of kieselguhr, 8-12 parts of sepiolite, 5-8 parts of precipitated barium sulphate, 13-16 parts of micro-capsulated red phosphorus, 3-4 parts of a preservative, 2-3 parts of a defoamer, 3-4 parts of a flatting agent and 5-6 parts of pigments, wherein modified polyurethane is prepared from polycaprolactone diol, polycarbonate diol, N,N-bis(2-hydroxyethyl)amino methylene diethyl phosphite, modified polytoluene diisocynate, diethylene glycol, 2-(hydroxymethyl)half-ester phenylborate, glucose, stannous octoate, bis(2-hydroxyethyl)aniline and N-propyl diethanolamine; modified polytoluene diisocynate is prepared by grafting polymerized polytoluene diisocynate with hydroxy siloxane.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

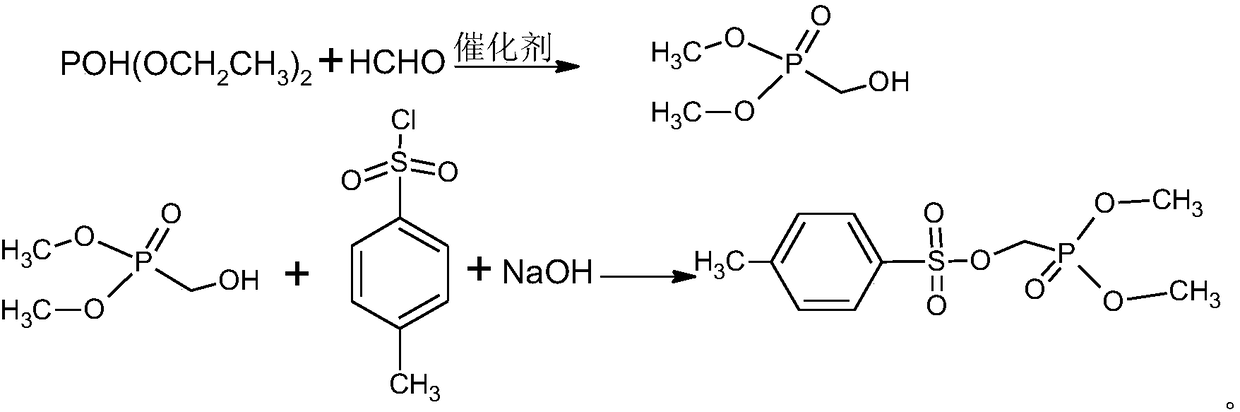

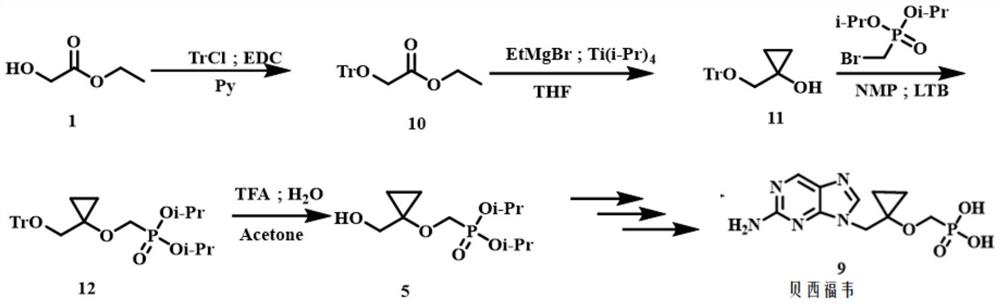

A kind of method for preparing besifovir

ActiveCN108997429BAvoid generatingReduce experiment costGroup 5/15 element organic compoundsO-Phosphoric AcidDiethyl methylphosphonate

The invention relates to a method for preparing P-[[[1-[(2-amino-9H-purine-9-yl) methyl] cyclopropyl] oxy] methyl]-phosphoric acid (Besifovir). The method comprises the following steps: 1) enabling acompound of formula (1) as shown in the specification to react with tertiary butyl diphenylchlorosilane so as to prepare a compound of formula (2) as shown in the specification; 2) enabling the compound of formula (2) to react with ethyl magnesium bromide so as to prepare a compound of formula (3) as shown in the specification; 3) enabling the compound of the formula (3) to react with p-toluenesulfonyl oxymethyldiethoxyphosphine under a condition that tertiary butanol lithium is adopted as an alkali so as to prepare a compound of formula (23) as shown in the specification; 4) carrying out ammonium fluoride hydrolysis on the compound of formula (23) so as to prepare a compound of formula (24) as shown in the specification; 5) enabling the compound of formula (24) to react with a compound offormula (28) as shown in the specification so as to prepare a compound as a solid of formula (22) as shown in the specification; 6) carrying out reduction dechloridation on the compound of formula (22) as shown in the specification under a condition of a catalyst and a hydrogen supplier so as to prepare a compound as a solid of formula (25) as shown in the specification; 7) carrying out trimethylbromide silane hydrolysis on the compound of formula (25), so as to obtain Besifovir as shown in the specification. The method is cheap in raw material and intermediate material, easy in raw materialand intermediate material obtaining, low in cost, high in yield, gentle in condition and good in security.

Owner:广州粤美医药科技有限公司

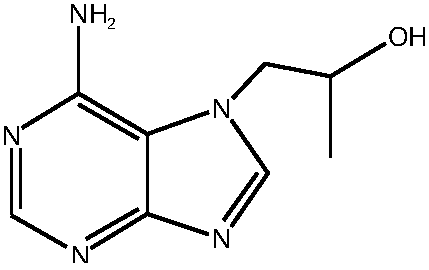

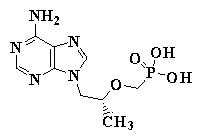

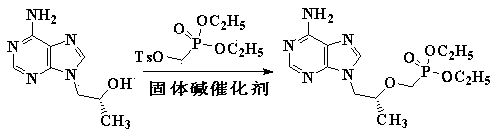

Preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine

ActiveCN105646585AHigh yieldReduce generationGroup 5/15 element organic compoundsAntiviral drugDiethyl methylphosphonate

The invention discloses a preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine, and relates to a preparation method of an antiviral drug for an acquired immune deficiency syndrome. The method comprises the steps that when (R)-9-[2-(diethyl phosphoryl methoxyl)propyl]-adenine is prepared, (R)-hydroxypropyl adenine and diethyl p-toluenesulfonyloxymethylphosphonate (DESMP) are subjected to a condensation reaction under the action of magnesium tert-butoxide to generate the (R)-9-[2-(diethyl phosphoryl methoxyl)propyl]-adenine; PMPA diethyl ester is subjected to deethylation through trimethylbromosilane by taking water as solvent to obtain the (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine (PMPA). According to the technology, the product yield is increased, the technology is cleaner, the production cost is lowered, the product yield is increased, the raw materials are easy to obtain, and industrialization is easy to achieve.

Owner:扬州三友合成化工有限公司

Hard-polyurethane-foam heat-insulating material

InactiveCN110591053AImprove performanceImprove insulation performanceChemical industryDiethyl methylphosphonateFire retardant

The invention relates to the technical field of preparation of polyurethane foam and discloses a hard-polyurethane-foam heat-insulating material. The hard-polyurethane-foam heat-insulating material comprises the following experiment raw materials: phosphorus-containing polyol, 1-azabicyclo[2.2.2]octane, 4,4-diphenylmethane diisocyanate, N,N-dimethyl cyclohexylamine, diisopropylethylamine, calciumphosphate, a sodium carbonate aqueous solution and lignin. According to the hard-polyurethane-foam heat-insulating material, a bipolymer is formed by the 4,4-diphenylmethane diisocyanate and the phosphorus-containing polyol and becomes a major component of the polyurethane foam material; the phosphorus-containing polyol is prepared from diethyl methylphosphonate and propylene glycol through an ester exchange reaction; compared with polyols, the phosphorus-containing polyol has the advantages that properties of polyurethane foam are enhanced, and the heat-insulating effect of the foam is improved; and the calcium phosphate serves as a high-melting-point flame retardant, and the heat-insulating effect of the lignin based polyurethane foam is greatly improved through regulating and controlling the consumption of the calcium phosphate.

Owner:厦门珉瑶贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate](https://images-eureka.patsnap.com/patent_img/23a05a85-6ead-4c54-bfa7-42def307c2ba/US20080004449A1-20080103-C00001.png)

![Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate](https://images-eureka.patsnap.com/patent_img/23a05a85-6ead-4c54-bfa7-42def307c2ba/US20080004449A1-20080103-C00002.png)

![Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate](https://images-eureka.patsnap.com/patent_img/23a05a85-6ead-4c54-bfa7-42def307c2ba/US20080004449A1-20080103-C00003.png)

![Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine](https://images-eureka.patsnap.com/patent_img/a420d299-45fc-4fb2-a07f-e5b66003a48f/DEST_PATH_151214094402.PNG)

![Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine](https://images-eureka.patsnap.com/patent_img/a420d299-45fc-4fb2-a07f-e5b66003a48f/DEST_PATH_151214094441.PNG)

![Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine Preparation method of (R)-9-[2-(phosphonomethoxy) propyl] adenine](https://images-eureka.patsnap.com/patent_img/a420d299-45fc-4fb2-a07f-e5b66003a48f/116369DEST_PATH_IMAGE005.PNG)

![Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate](https://images-eureka.patsnap.com/patent_img/a85106c8-4256-4c41-afbb-1b2e0b2182a6/US07687631-20100330-C00001.png)

![Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate](https://images-eureka.patsnap.com/patent_img/a85106c8-4256-4c41-afbb-1b2e0b2182a6/US07687631-20100330-C00002.png)

![Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate Synthesis of diethyl{[5-(3-fluorophenyl)-pyridine-2yl]methyl}phosphonate](https://images-eureka.patsnap.com/patent_img/a85106c8-4256-4c41-afbb-1b2e0b2182a6/US07687631-20100330-C00003.png)

![Preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine Preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine](https://images-eureka.patsnap.com/patent_img/099b9d3f-eb26-47a2-924c-b8c1414daf4b/160204153919.PNG)

![Preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine Preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine](https://images-eureka.patsnap.com/patent_img/099b9d3f-eb26-47a2-924c-b8c1414daf4b/489278DEST_PATH_IMAGE003.PNG)

![Preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine Preparation method of (R)-9-[2-(phosphoryl methoxyl)propyl]-adenine](https://images-eureka.patsnap.com/patent_img/099b9d3f-eb26-47a2-924c-b8c1414daf4b/697537DEST_PATH_IMAGE004.PNG)