A kind of preparation method of n,n-bis(2-hydroxyethyl)aminomethylphosphonic acid diethyl ester

A technology of diethyl aminomethylphosphonate and diethyl phosphite, applied in the field of N, can solve problems affecting product quality and later application, increasing energy consumption of production process, unfavorable formation of intermediates, etc., and achieve product yield High, less catalyst consumption, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

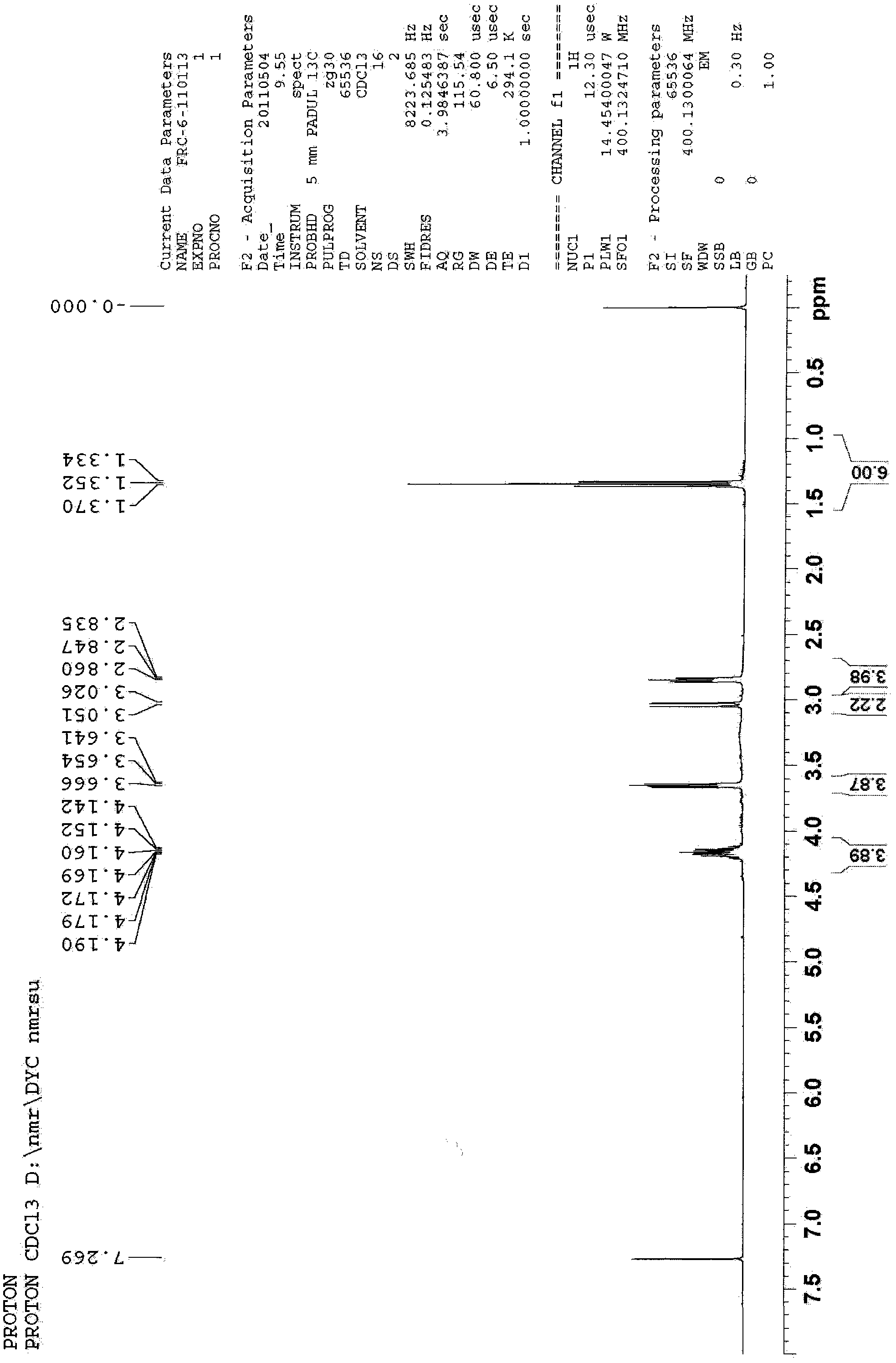

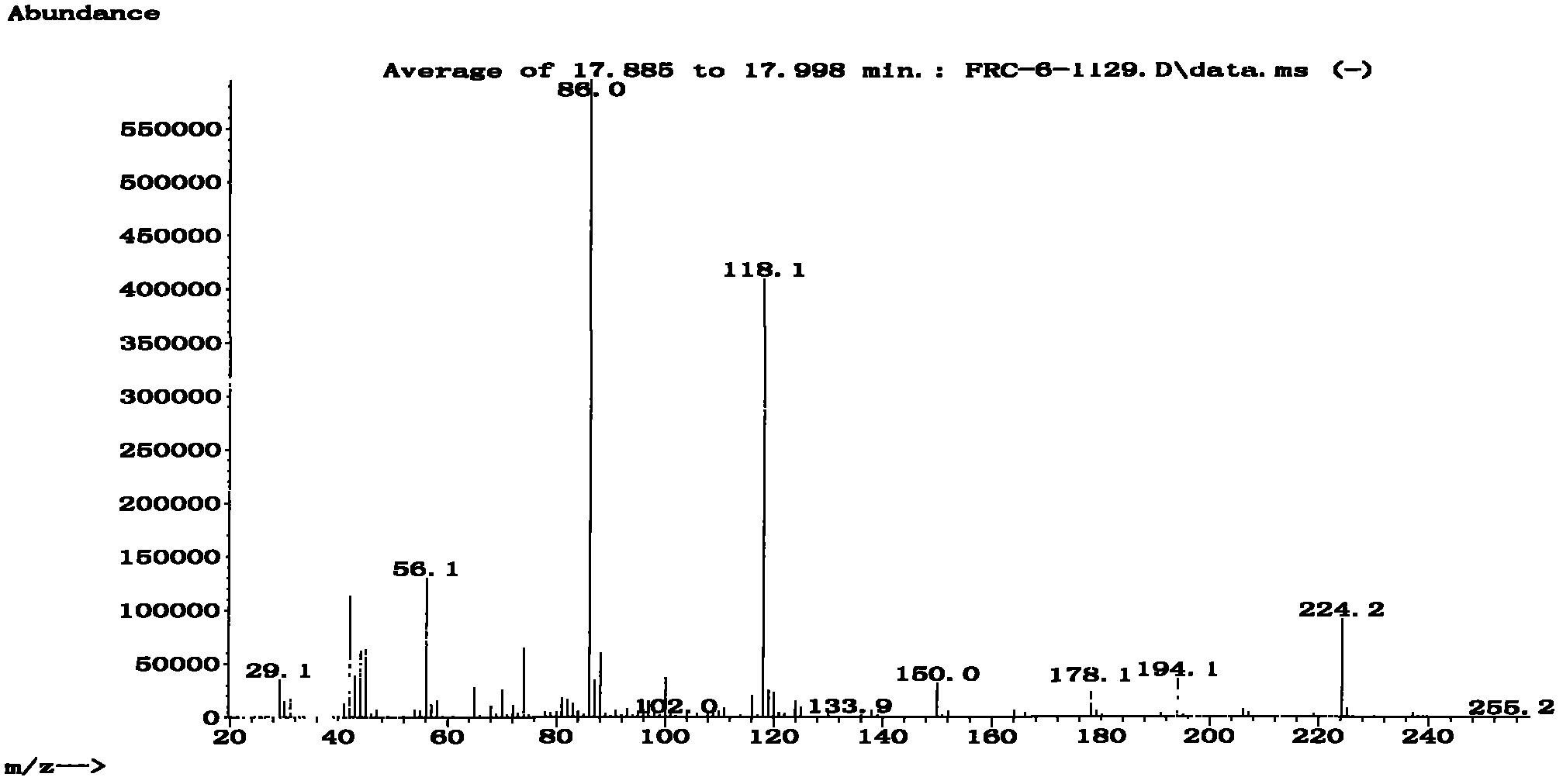

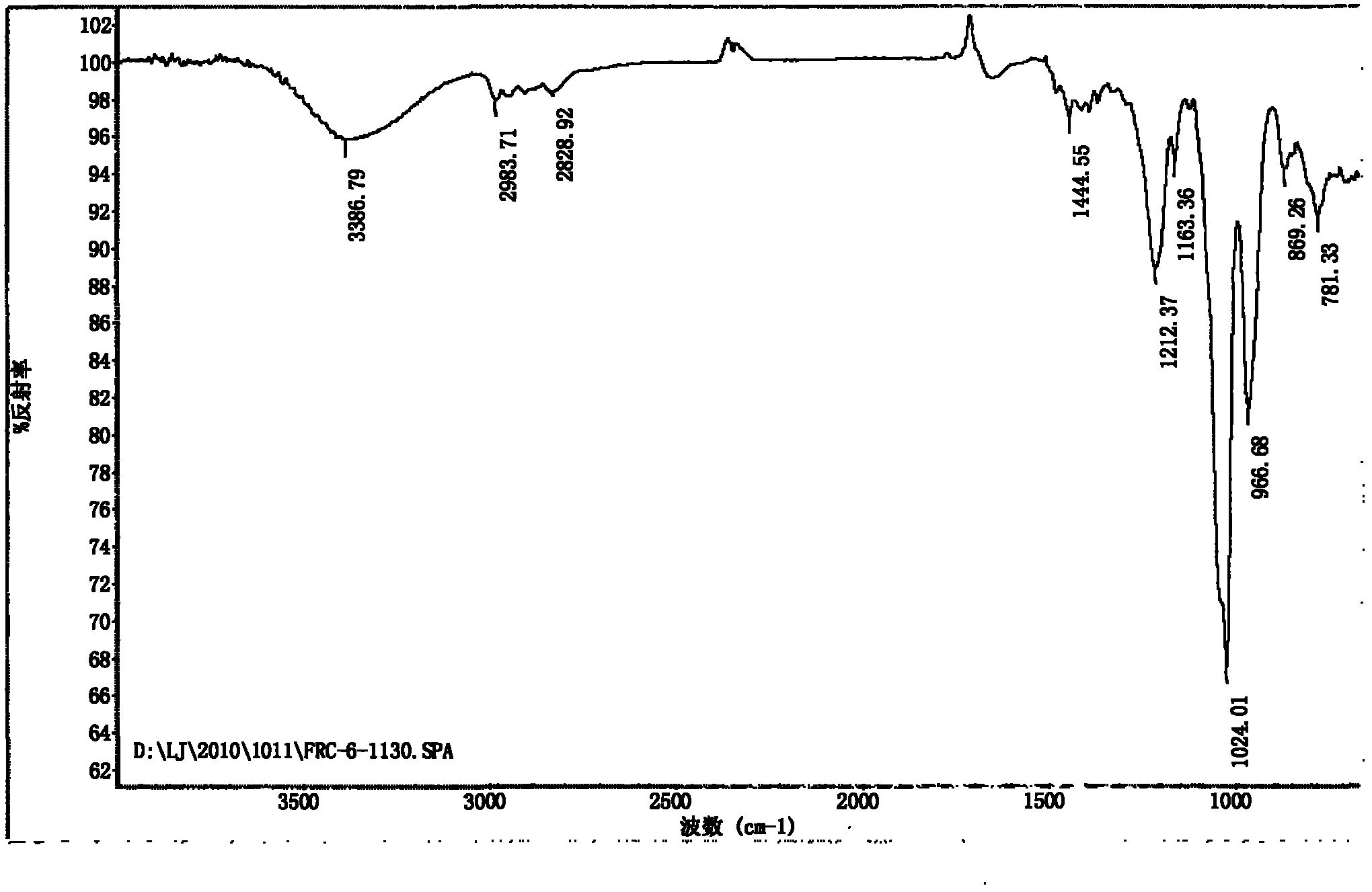

Image

Examples

Embodiment 1

[0032] 1. Weigh 360 parts of n-propanol in a 2L three-neck flask equipped with a magnetic stirrer, a constant pressure dropping funnel and a thermometer, raise the temperature to 70°C, add 180 parts of paraformaldehyde solid, and adjust the polyformaldehyde with sodium hydroxide solution The pH of the formaldehyde solution is 9-11, until the paraformaldehyde is completely dissolved, and the temperature is lowered to 30°C.

[0033] 2. Weigh 78 parts of anhydrous sodium sulfate into a three-necked flask, weigh 573 parts of diethanolamine in a constant pressure dropping funnel, slowly add diethanolamine under stirring, the reaction is an exothermic reaction, control the reaction temperature at 40°C , after the dropwise addition of diethanolamine was completed, the temperature was kept at 40° C., and the reaction was continued for 1 hour. Then the temperature was lowered to 30°C, and the sodium sulfate after absorbing water was removed by filtration.

[0034]3. Raise the temperat...

Embodiment 2

[0047] 1. Weigh 222 parts of n-butanol in a 2L three-neck flask with a magnetic stirrer, a constant pressure dropping funnel and a thermometer, raise the temperature to 80°C, add 180 parts of paraformaldehyde solid, and adjust the polyformaldehyde with sodium hydroxide solution The pH of the formaldehyde solution is 9-11, until the paraformaldehyde is completely dissolved, and the temperature is lowered to 30°C.

[0048] 2. Weigh 100 parts of calcium oxide into a three-necked flask, weigh 623.8 parts of diethanolamine in a constant pressure dropping funnel, slowly add diethanolamine under stirring, the reaction is an exothermic reaction, control the reaction temperature at 40°C, After the ethanolamine was added dropwise, the temperature was raised to 50° C., and the reaction was continued for 0.5 hours. Then the temperature was lowered to 30°C, and the calcium oxide after absorbing water was removed by filtration.

[0049] 3. Raise the temperature to 45-50°C, under the condit...

Embodiment 3

[0053] 1. Weigh 700 parts of isopropanol in a 2L three-neck flask equipped with a magnetic stirrer, a constant pressure dropping funnel and a thermometer, raise the temperature to 60°C, add 180 parts of paraformaldehyde solid, and adjust the polyformaldehyde with sodium hydroxide solution The pH of the formaldehyde solution is 9-11, until the paraformaldehyde is completely dissolved, and the temperature is lowered to 30°C.

[0054] 2. Weigh 80 parts of anhydrous calcium sulfate into a three-necked flask, weigh 519.8 parts of diethanolamine in a constant pressure dropping funnel, slowly add diethanolamine under stirring, the reaction is an exothermic reaction, control the reaction temperature at 30°C , after the addition of diethanolamine was completed, the temperature was kept at 30° C., and the reaction was continued for 2 hours. Calcium sulfate after absorbing water was removed by filtration.

[0055] 3. Raise the temperature to 45-50°C, under the condition that the degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com