Halogen-free flame-retardant textile finishing agent as well as preparation method and application thereof

A technology for flame-retardant fabrics and finishing agents, applied in fiber treatment, textile and papermaking, fiber types, etc., can solve problems such as environmental pollution, and achieve the effects of good durability, little secondary pollution, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

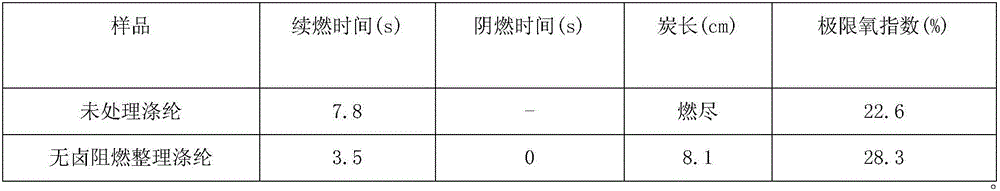

Examples

Embodiment 1

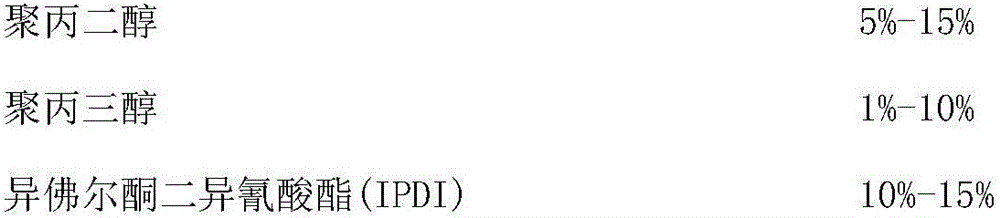

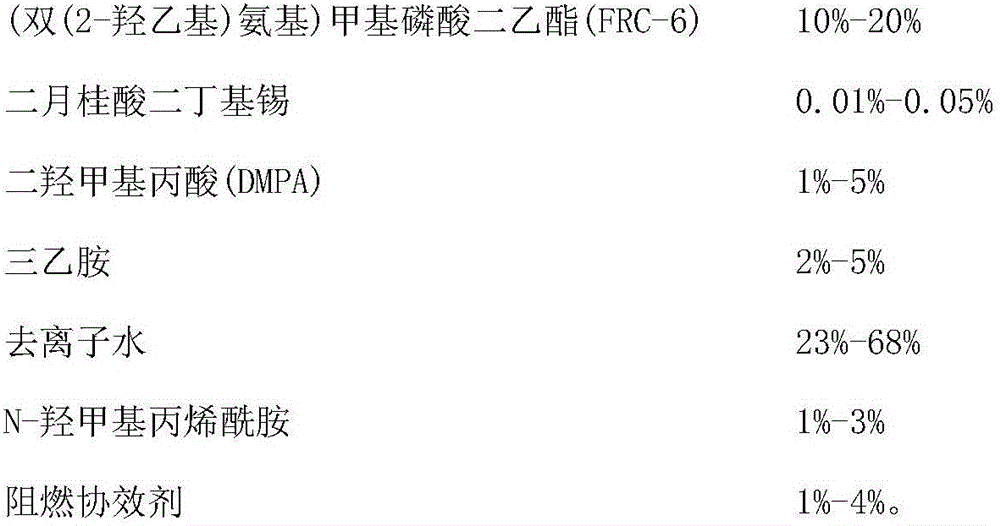

[0031] A preparation method of a halogen-free flame-retardant fabric finishing agent, specifically comprising the following steps:

[0032] (1) Weigh 12 g of polypropylene glycol and 5 g of polyglycerol, respectively, place them in completely dry three-neck flasks with thermometers, and treat them at 120 ° C and 140 ° C for 2 hours under the condition of a vacuum of 0.01 atm;

[0033] (2) Pour the pretreated polypropylene glycol and polyglycerol into the same three-necked flask after being lowered to normal temperature, install the stirring device, start the stirrer, add isophorone diisocyanate 8g, (bis(2-hydroxy Ethyl)amino)methyl diethyl phosphate 10g, a drop of dibutyltin dilaurate, start to slowly heat up to 70°C, and react at a constant temperature for 120min;

[0034] (3) After the reaction, cool the system down to 60°C, add a certain amount of acetone and stir for 10 minutes, add 2g of dimethylolpropionic acid, raise the temperature of the system to a constant temperatu...

Embodiment 2

[0048] A preparation method of a halogen-free flame-retardant fabric finishing agent, specifically comprising the following steps:

[0049] (1) Weigh 12 g of polypropylene glycol and 5 g of polyglycerol respectively, place them in completely dry three-neck flasks with thermometers, and treat them at 120° C. and 140° C. for 2 hours under vacuum of 0.01 atm;

[0050] (2) Pour the pretreated polypropylene glycol and polyglycerol into the same three-necked flask after being lowered to normal temperature, install the stirring device, start the stirrer, add isophorone diisocyanate 4g, (bis(2-hydroxy Ethyl) amino) methyl phosphate 14g, a drop of dibutyltin dilaurate, began to slowly heat up to 70 ° C, constant temperature reaction 120min;

[0051] (3) After the reaction, cool the system down to 60°C, add a certain amount of acetone and stir for 10 minutes, add 2g of dimethylolpropionic acid, raise the temperature of the system to a constant temperature of 70°C, and react for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com